Table of Contents

From Fryer to Flight: why restaurants matter to SAF

Used cooking oil is an approved feedstock in ASTM D7566 Annex A2 for the hydroprocessed esters and fatty acids (HEFA) pathway that supplies nearly every commercial SAF gallon today, according to ICAO data. Clean, low water oil can cut life cycle jet fuel emissions by up to 94 percent when compared with fossil Jet A, the U.S. Alternative Fuels Data Center notes.

That means the quality decisions you make at the fryer ripple all the way to the runway. With EPA’s 2023 25 Renewable Fuel Standard letting SAF producers claim advanced biofuel RINs, demand for traceable, high grade UCO has surged. On site filtration is the first, cheapest step in that value chain, and it starts under your hood, not at the refinery.

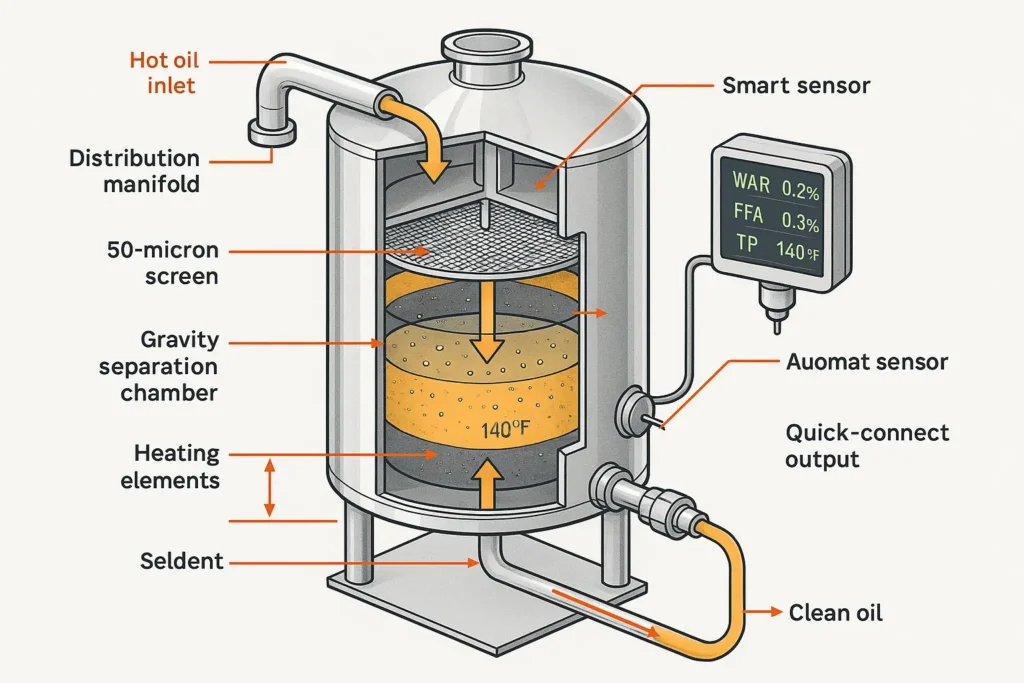

Two minute tech: how closed loop filtration works

Hot oil drains straight from the fryer through insulated piping into a sealed stainless tank. Inside, a 50 micron screen and gravity chamber separate crumbs, ice crystals, and water while the oil stays above 140 °F, the sweet spot where contaminants settle fastest, NREL’s 2024 HEFA report confirms.

A smart probe alerts staff if water rises above 0.1 percent, so every pickup meets refinery specs without extra chemical wash. When your used collection company arrives, a quick connect hose empties the tank: no buckets, no burns. The entire cycle takes less than two minutes of labor per day yet protects every gallon on its trip to the SAF plant.

Cleaner oil, lower carbon: the science that sells

| Impurity | Unfiltered barrel | On site filtered | HEFA target |

|---|---|---|---|

| Free fatty acids | 12 to 20 % | 5 to 9 % | < 1 % |

| Water | 1 to 2 % | ≤ 0.2 % | ≤ 0.05 % |

| Solids/metals | Visible sludge | Trace | Near zero |

Laboratory snapshots above mirror ranges in NREL’s 2024 state of industry dataset. Every point of impurity you drop saves hydrogen, caustic soda, and clay at the refinery, directly lowering a SAF batch’s carbon intensity (CI). According to the IRS draft rules for the §45Z Clean Fuel Production Credit, SAF that beats a 50 percent CI reduction can earn up to $1.75 per gallon in 2025. Exporting cleaner oil lets your buyers hit that mark and pay you more for every tote.

Policy turbo boost: RFS, IRA & other acronyms that pay

EPA’s current RFS set rule labels HEFA SAF gallons “advanced biofuel,” letting refiners stack D4 RINs on top of market price. Starting 1 January 2025, the Inflation Reduction Act’s §45Z adds a performance based clean fuel credit worth up to $1.75 / gal for low CI SAF, the IRS draft notice shows. Because CI falls with lower free fatty acids and water, restaurants that ship refinery ready UCO ride that upside through premium rebates from buyers: no paperwork required on your end.

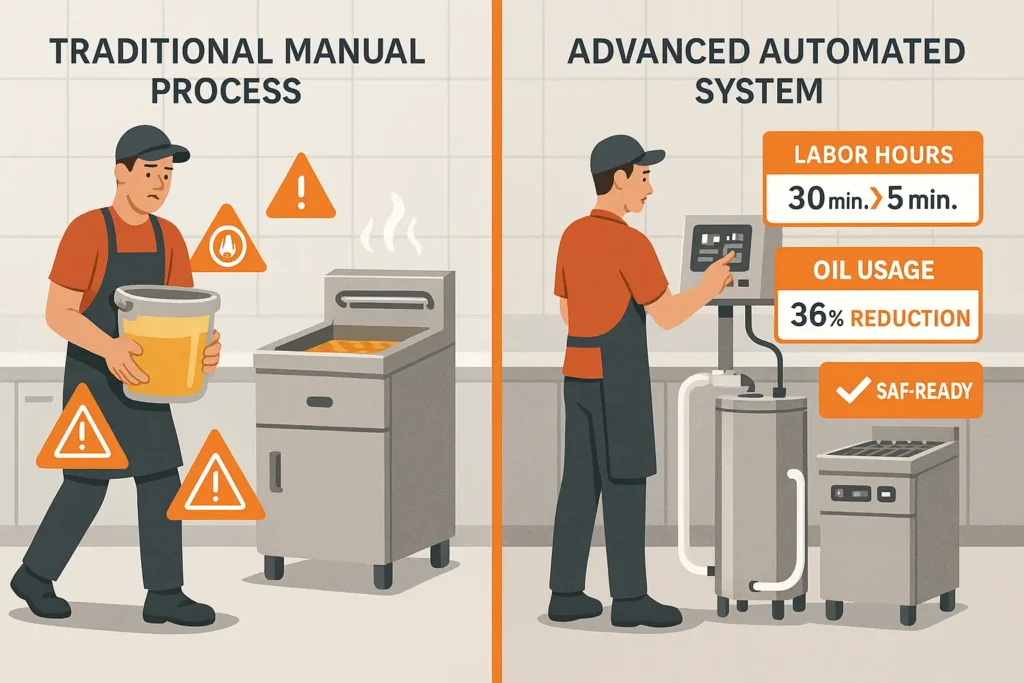

Safety & staffing wins you’ll notice tomorrow

OSHA’s accident log lists hundreds of hot oil burns each year; many involve workers carrying open fryer pots across the floor. Closed loop pipes eliminate that hazard and, because used cooking oil’s flash point is above 200 °F, it counts as a Class IIIB combustible liquid under NFPA 30, which means fewer costly electrical upgrades when the oil stays enclosed. Insurance carriers reward the risk drop with up to 15 percent lower premiums, Restaurant Technologies notes in its 2024 customer survey. Safer, simpler shifts also help retain cooks in a tight labor market.

Dollars & sense: what restaurants actually save

| Cost lever | Old school buckets | Closed loop system | Annual swing* |

|---|---|---|---|

| Fryer downtime | 30 min/day | 5 min/day | -$2,500 |

| Oil purchases | 50 lb/week | 32 lb/week | -$5,000 |

| Insurance | baseline | -15 % | -$1,200 |

*Figures reflect 150 seat casual concept in RTI’s 301 restaurant survey. Add the buyer premium for refinery ready oil, often 10 to 15 cents per pound in current spot deals (check with your local used collection company), and most sites recoup installation in under 12 months. According to NREL, HEFA SAF margins stay positive up to a $0.55 / kg feedstock price, so quality oil keeps you in demand even when markets swing.

Traceability beats fraud and boosts premiums

Rising imports of suspect “fake UCO” from Asia have triggered Reuters reported fraud probes on both sides of the Atlantic. EPA has already begun auditing supply chains of U.S. renewable fuel makers to verify origin claims. Grease Connections’ cloud linked sensors stamp every gallon with time, temperature, and location, giving refineries the proof they now demand. That audit trail earns preferred supplier status and can push rebate offers even higher.

Step by step: switch your kitchen in seven days

- Day 1: Site walk through; measure fryer height, door width, and floor slope.

- Day 3: Permit packet: Grease Connections handles NFPA 96 and plumbing sign off.

- Day 5: Pre built tank rolls in; piping drops through the hood flange with no menu disruption.

- Day 6: Online training; staff practice a live drain and filter run that takes 90 seconds.

- Day 7: First pickup scheduled; digital portal shows oil quality trending green. Most installs finish without shutting down service, and the same design fits food courts, ghost kitchens, or stadium concessions across the East Coast.

Choose the partner who stands behind every gallon

Grease Connections was built for one job: turn fryer waste into a flight worthy asset. We serve every ZIP code in Florida, Georgia and New Jersey, integrate with any used collection company, and guarantee your oil meets HEFA pretreat specs, or we pay the difference.

Book a five minute call to see a custom savings model and, if you’re in Florida, check our Miami service page for a live deployment map. Your next basket could power the next flight. Let’s start today.