Table of Contents

“We fill a 1,000 gallon tank every week what’s the smartest move?”

Georgia classifies you as a significant industrial user if you discharge 25,000 gallons of process water a day or fall under Categorical Pretreatment Standards both common in manufacturing kitchens and airline commissaries. That status triggers a local pretreatment permit, quarterly inspections, and strict manifest control under State Rule 391 3 6 .24. The real challenge isn’t the paperwork; it’s optimizing pickup cadence so oil never sits long enough to oxidize yet is voluminous enough to command top rebates from processors.

Option 1 Designing Bulk Storage & Scheduled Vacuum Service

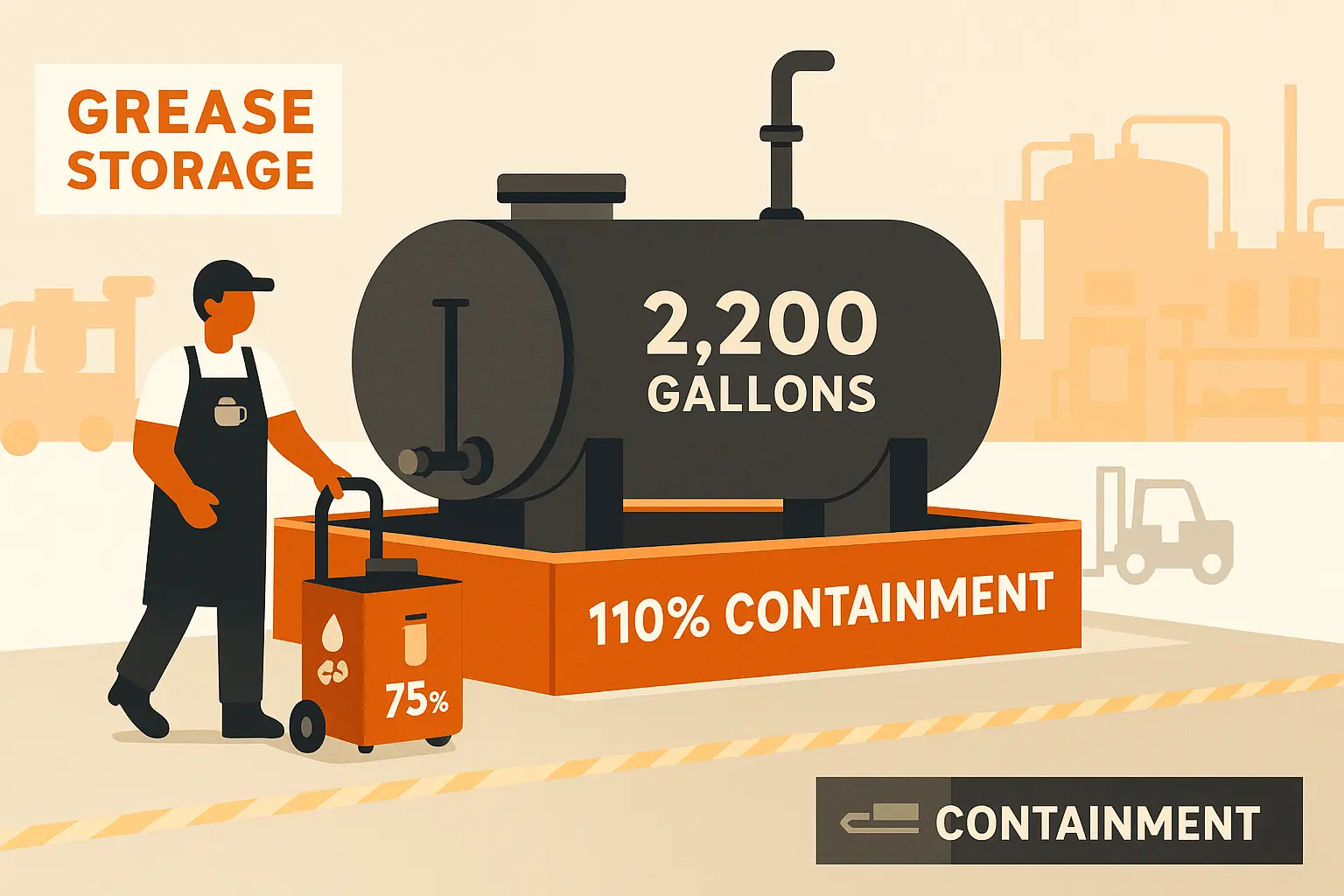

Atlanta’s FOG ordinance (§154 297.01) allows above ground double wall tanks as long as secondary containment equals 110 % of volume and vent lines reach roof height. Facilities typically install 1,000 or 2,200 gallon steel “farm tanks” plumbed to stainless quick disconnects so drivers stay outside the hygiene zone.

Companies out there offer stock tanks up to 500 gallons, but Grease Connections fabricates units to 5,000 gallons so industrial fryers can drain directly via hard line. Vacuum truck fleets such as Grease Connections pull 5,300 CFM at 28″ Hg, emptying a 2,000 gallon belly in under 15 minutes. Service intervals scale from twice weekly to monthly; manifests upload to EPD’s portal within 24 hours, satisfying auditors and keeping insurance premiums low.

Table 1 Bulk Tank Selection for High Volume Generators

| Capacity | Footprint | Best Fit | Typical Pickup Cadence |

|---|---|---|---|

| 500 gal cube | 5’×5′ | Micro brewery kitchen | Weekly |

| 1,000 gal vertical | 6’×6′ | University dining hall | Bi weekly |

| 2,200 gal horizontal | 8’×10′ | Snack plant | Weekly |

| 5,000 gal split compartment | 10’×18′ | Industrial food processor | Twice weekly |

Vertical tanks exploit head height where floor space is scarce, while split compartment horizontals let QA teams isolate allergen batches without doubling hardware.

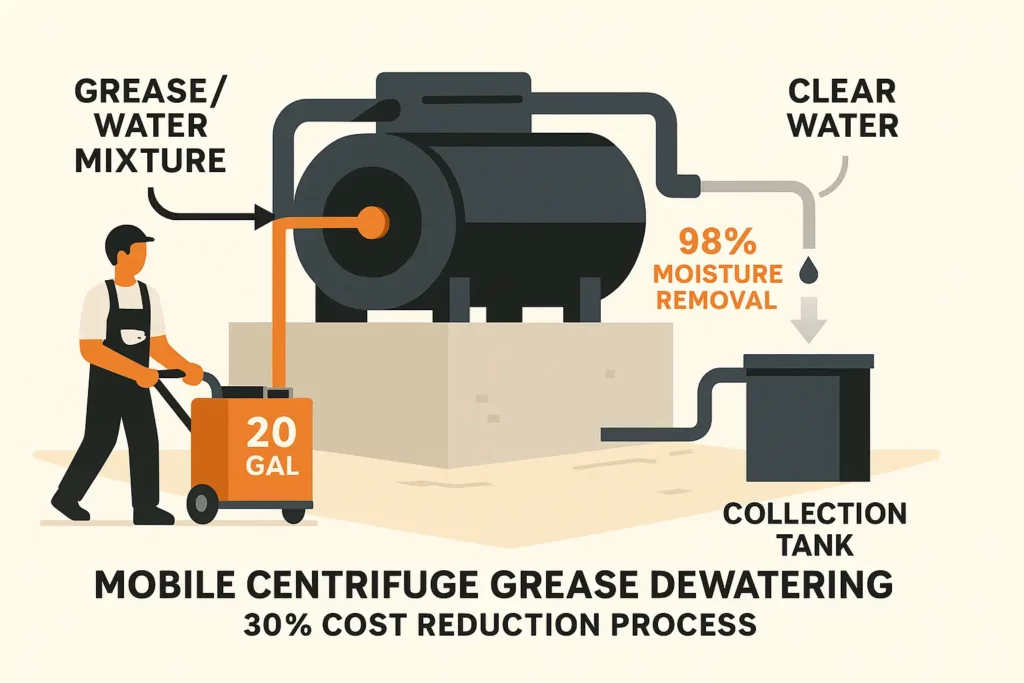

Option 2 Pretreatment + Sludge Dewatering

Vacuum fleets such as Grease Connections pair tanker removal with on site centrifuges that spin residual water to <2 % moisture, reducing load weight and off site disposal fees by 30 %. Grease Connections national network then transports the concentrated grease cake to regional renderers, producing tallow and renewable diesel while guaranteeing cradle to grave tracking. Under EPA’s Pretreatment Program (40 CFR 403.5), sludge with <10 % free liquids may bypass POTW surcharges if documented, a loophole Atlanta inspectors support when lab sheets accompany manifests.

Option 3 Biodiesel Revenue Share Agreements

Grease Connections has no long term contracts, however similar processors sign three year take or pay contracts that credit generators 15 to 25 ¢ per gallon above WTI spot when volumes exceed 10,000 gal/month. Because yellow grease trades on the Chicago Board of Trade, locking price bands protects against diesel volatility. Facilities often dedicate a 500 gal “day tank” for quality sampling before every haul; poor titration scores downgrade rebates, so a simple inline heater pays for itself by preventing cold weather polymerization, a tip Grease Connections shares during onboarding.

Compliance & Paperwork Why Large Volume Means Zero Margin for Error

Atlanta’s Watershed Department levies up to $2,400 in annual permit fees for facilities with 36 to 40 grease traps. Fulton County’s Commercial Pretreatment Unit cross checks manifests against vacuum truck GPS logs, citing mismatches as “false reporting” with fines that eclipse disposal costs. State inspectors also verify that every tanker bears an EPD registration sticker missing numbers trigger immediate service suspension and possible criminal charges under Rule 391 3 6 .24. Keeping a three year digital archive and a 30 day cab copy meets both state and federal record retention rules.

Table 2 Pickup Frequency vs. Generation Rate

| Weekly Oil Volume | Recommended Tank Size | Optimal Service Interval |

|---|---|---|

| <500 gal | 1,000 gal | Every 14 days |

| 500 to 1,200 gal | 2,200 gal | Weekly |

| 1,200 to 2,500 gal | 5,000 gal | Twice weekly |

| >2,500 gal | Twin 5,000 gal | 3× per week |

Case Study: Snack Manufacturer Cuts Haul Costs 42 %

A South Fulton chip plant once dispatched five 300 gal totes daily. By installing a 5,000 gal split tank and switching to Cowart Industrial’s high CFM tanker, it reduced weekly trips from 5 to 2 and secured a 22 ¢/gal biodiesel premium, saving $3,800 a month. The “aha” moment came when engineers realized transport fees, not trap pumping, were the profit leak.

For campuses, plants, or airlines ready to turn oily waste into a revenue stream, Grease Connections engineers, installs, and services every gallon so you stay compliant and profitable across Atlanta, Augusta, Savannah, Macon, and beyond.