Table of Contents

Key takeaway: Rapid advances, from AI assisted feedstock grading to refinery co processing, are driving double digit percentage savings across every major step of used cooking oil (UCO) conversion, making low carbon fuels more competitive with petroleum diesel. Below, we unpack the nine technologies most responsible for slashing capex, opex, and energy intensity.

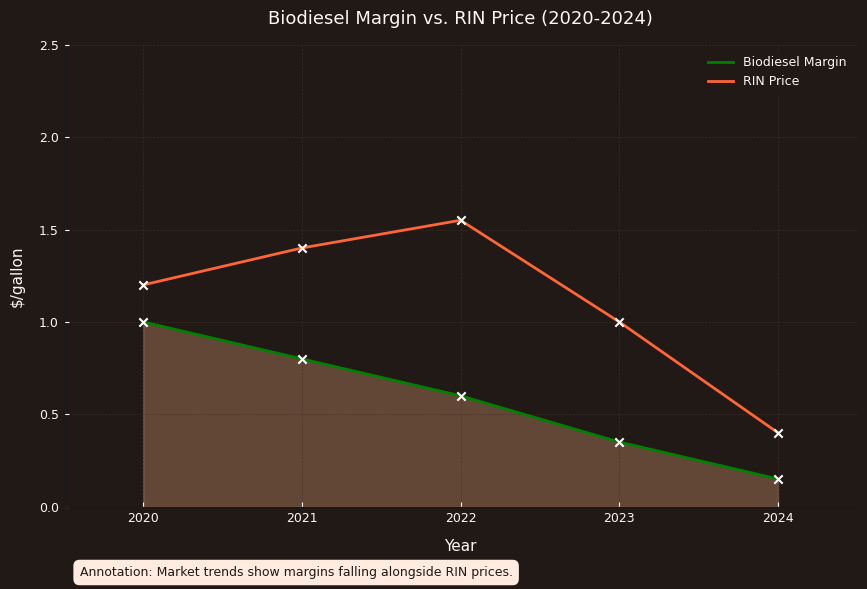

Why cost matters in UCO conversion

Feedstock now accounts for 70 to 90% of biodiesel production cost, so any technology that raises yield or lowers chemical use shifts the profit curve dramatically. Falling RIN prices and a renewable diesel glut add urgency by squeezing margins across North America.

AI driven feedstock grading and smart collection

Optical gas sensing IoT probes mounted inside 55 gallon drums now score FFA levels in real time, letting haulers route only in spec loads to processors and avoid costly acid pretreatment. Blockchain tags on each 70 gallon caddy maintain tamper proof custody records that meet new EU traceability rules, cutting audit overhead.

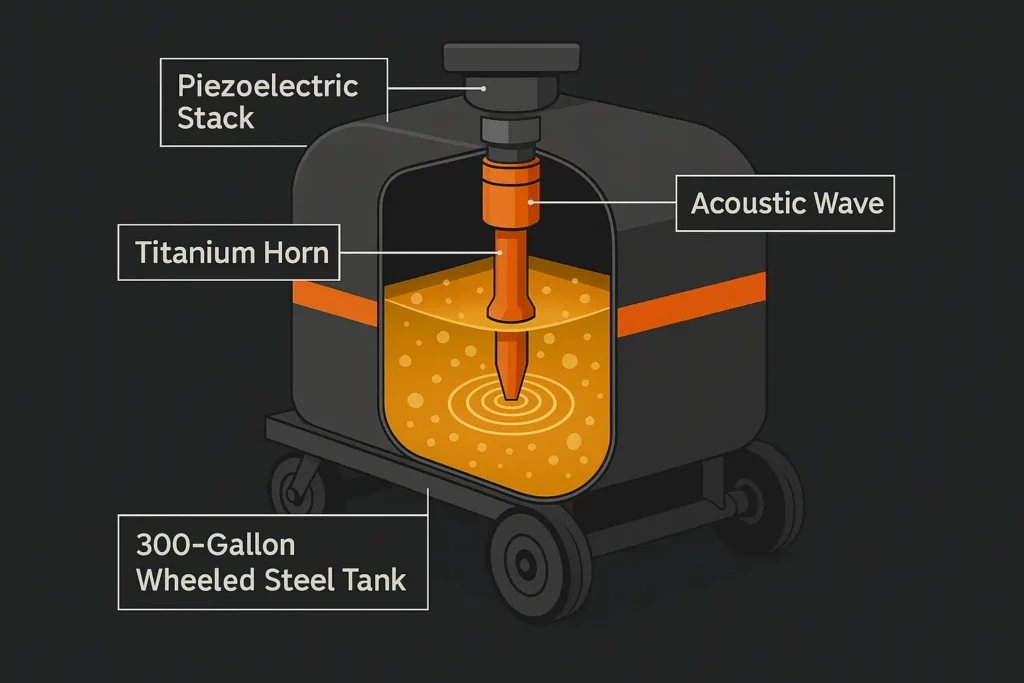

Ultrasonic & microwave pretreatment

Ultrasonic cavitation breaks fatty acid chains in seconds, trimming reaction times to minutes and reducing methanol use by up to 30%. Pilot microwave reactors run on recovered fryer heat, lowering pretreatment energy by 18% in side by side trials.

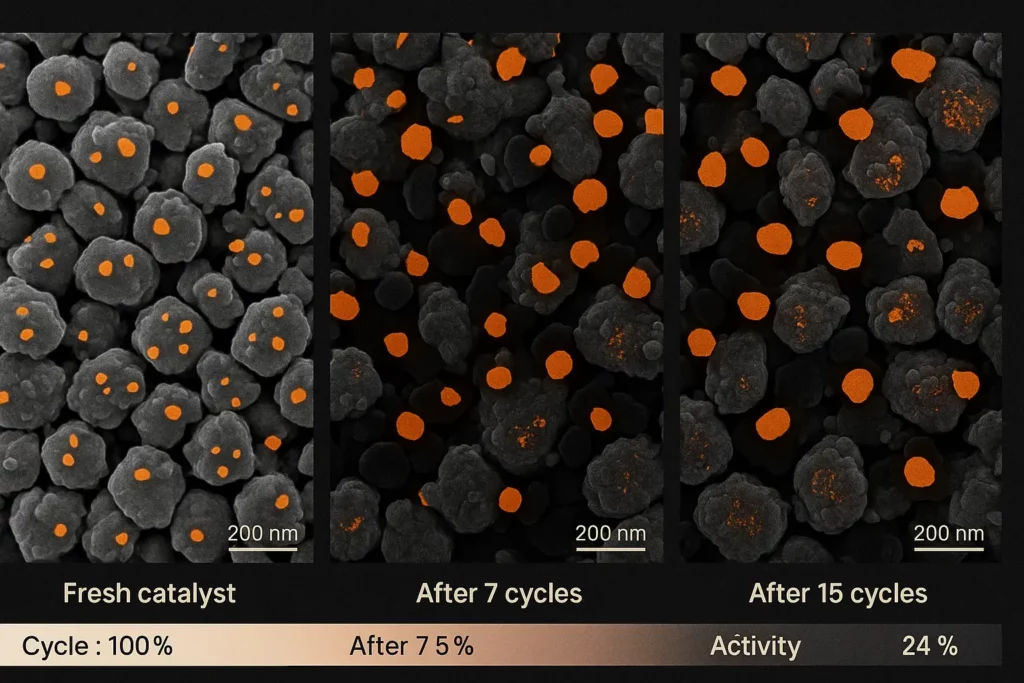

Solid and enzyme catalysts slash chemical spend

Reusable CaO nanocatalysts eliminate neutralisation and halve wastewater generation, extending catalyst life to 15 cycles without activity loss. Immobilised lipase now delivers >94% conversion at 40 °C, saving 25% in heating costs and allowing lower grade UCO feed.

Continuous flow microreactors & modular skids

Credit card sized micro channels achieve residence times under 5 s, cutting reactor volume, and capex, by 90%. Containerized rotating tube units process 2 ML/yr and can be stacked at quick service restaurant depots, trimming logistics miles by 40%.

Snapshot of impact

| Innovation | Typical cost saving | Commercial maturity |

|---|---|---|

| AI grading | 4 to 7 ¢/L opex | Early pilots |

| Ultrasonic | 6 to 9 ¢/L energy/chem | Demo scale |

| Solid catalyst | 3 to 5 ¢/L chem & effluent | Scaling |

| Microreactor | 20 to 30% capex | Niche commercial |

| Membrane polish | 2 to 4 ¢/L utilities | Commercial |

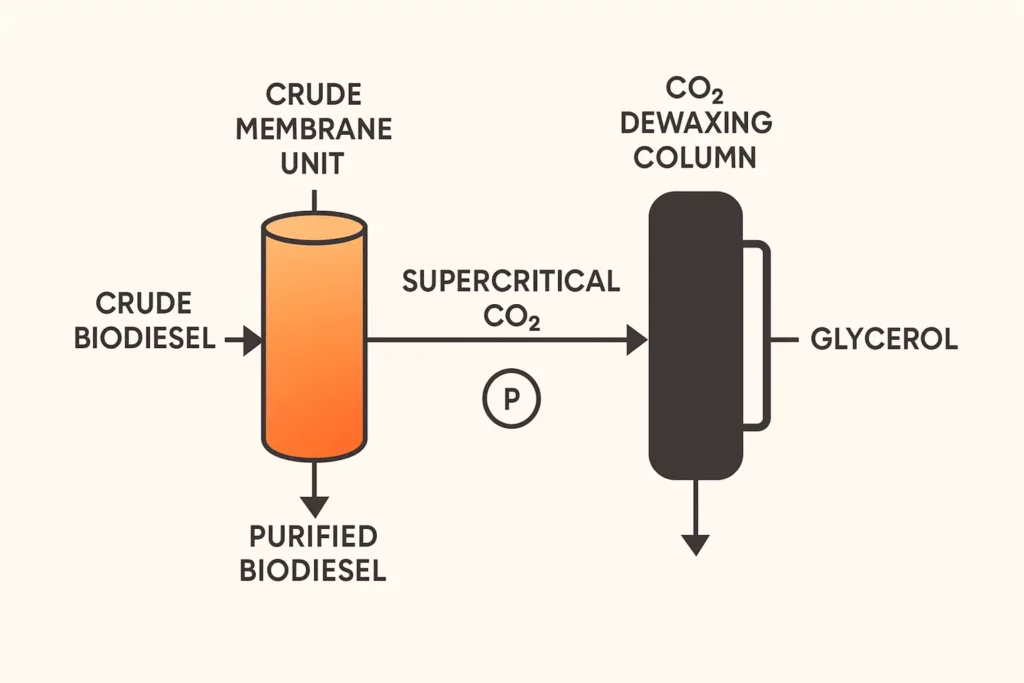

Membrane & supercritical downstream polishing

Hybrid ceramic membranes strip glycerol to 0.02 wt%, meeting ASTM D6751 in one pass and cutting water wash volumes by 80%. Supercritical CO₂ dewaxing simultaneously dries and degums biodiesel, trimming utility loads by 15%.

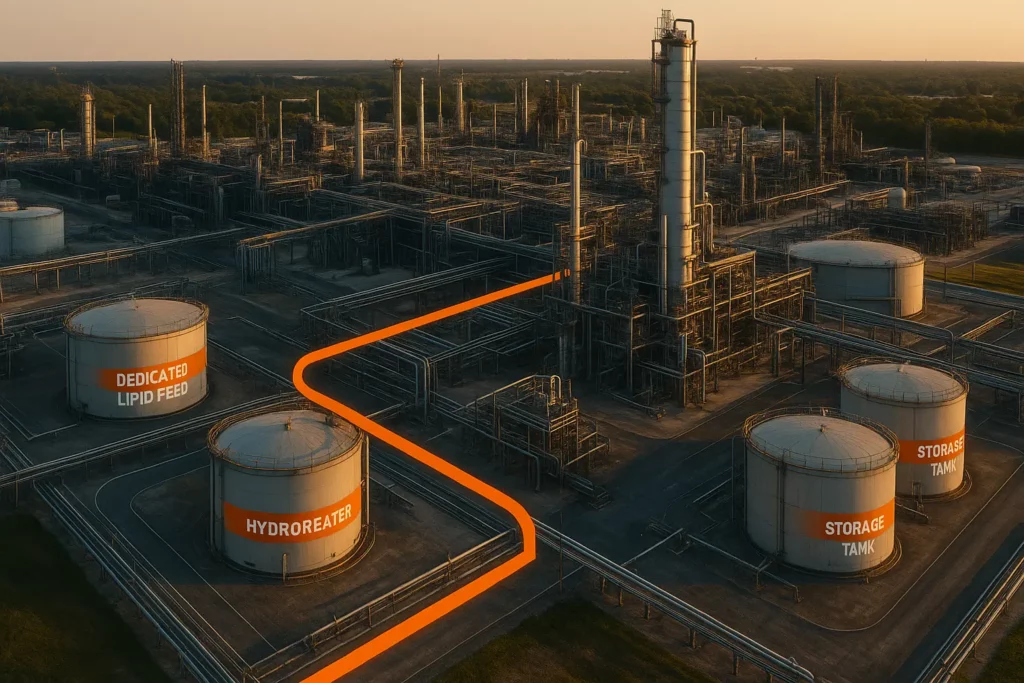

Hydroprocessing & refinery co processing

Hydrotreated vegetable oil (HVO) units integrated in existing hydrotreaters convert UCO directly to renewable diesel at 88% overall yield. OMV’s new Schwechat line proves co processing can handle 160 kt/yr without new greenfield builds, slicing capex per barrel by 45%.

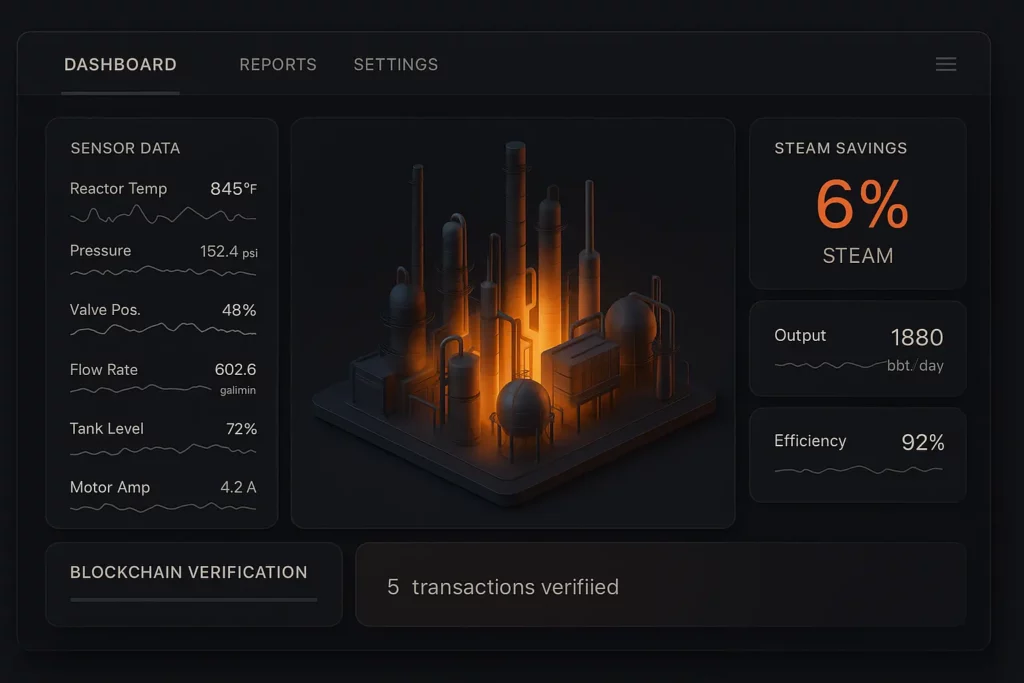

Digital twins, blockchain & advanced analytics

Real time digital twins mirror every valve and sensor, optimizing heat integration and saving 4 to 6% in steam annually. Smart contracts on blockchain automate sustainability credit claims, shaving weeks off compliance cycles while guarding against “virgin oil laundering.”

Implementation roadmap

- Start with IoT drum sensors to tighten FFA specs.

- Retrofit ultrasonic horns to existing kettles.

- Trial a skid mounted microreactor on a side stream.

- Transition to solid base catalysts and membrane polish.

- Leverage blockchain and digital twin analytics to close the optimisation loop.

Each step builds modularly, allowing payback in under three years at $0.80 L biodiesel pricing.