How do I stop my grease trap from smelling?

Pour 2 gallons of boiling water mixed with 1 cup high-grease-cutting dish soap (e.g., Dawn) down all drains, wait 20 minutes, then flush with cold water. Add weekly enzyme treatments to prevent future odors and keep your trap working properly.

This emergency grease trap smell fix works because hot water liquefies trapped grease while soap breaks it down, ridding your kitchen of foul odors. The enzymes are beneficial bacteria that continuously eat grease between cleanings, essentially preventing bad smells from developing. Stop grease-trap odors fast with this proven method.

For long-term odor prevention:

- Run hot water (as hot as tap delivers, ideally 120 °F / 49 °C) for 60 seconds nightly

- Add enzyme digesters weekly to eliminate buildup

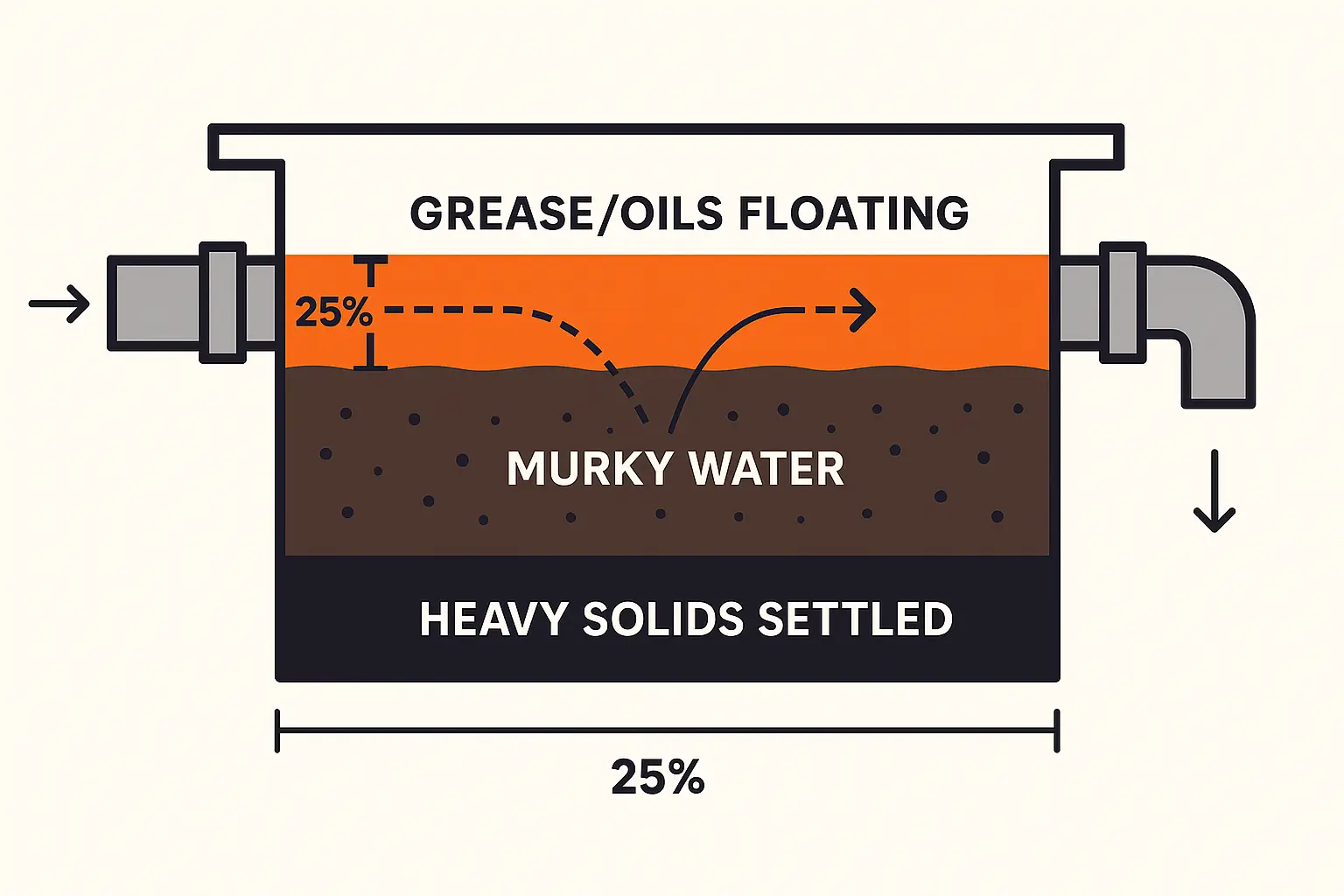

- Pump trap when 25% full to stay safe from overflows

- Never pour grease directly down drains

Regular cleaning and maintenance make a significant difference in preventing grease trap odors that frequently affect restaurant property and family businesses alike.

Summary: Stop grease trap smells immediately with hot water and dish soap flush, then maintain with weekly enzyme treatments that digest odor-causing bacteria, monthly inspections, and pumping every 1–3 months to prevent recurring odors.

How do I know if my grease trap is clogged?

Your grease trap is clogged when water backs up from one sink into another, multiple drains are slow, or you hear gurgling sounds from pipes. These clogs occur when food particles and grease solidify in your trap compartments.

The definitive test: Fill a sink with water and time how long it takes to drain. Healthy drains empty in under 30 seconds. Over 60 seconds means you have a clog that will only get worse without proper cleaning.

Other warning signs that frequently develop:

- Bad smells from all drains and sinks

- Grease appearing outside the trap or in your parking lot

- Water standing in sinks that won’t drain properly

- Sewage backing up (prepare for emergency pumping)

Each emergency type needs a different solution, but all indicate your trap needs immediate attention.

Summary: Multiple slow drains, water backing up between sinks, gurgling sounds, and drainage taking over 60 seconds are definitive signs of a clogged grease trap requiring immediate professional pumping to prevent sewage backup.

What are the fumes from a grease trap?

Grease trap fumes are hydrogen sulfide (rotten egg smell), methane (odorless but flammable), ammonia (sharp smell), and carbon dioxide. These gases form when bacteria break down trapped food particles and grease, releasing chemicals into the air.

These fumes pose real dangers and can affect your health:

- Hydrogen sulfide: Toxic at high concentrations, causes headaches

- Methane: Fire and explosion risk, especially near pilot lights

- Ammonia: Respiratory irritation that gets worse with exposure

- Carbon dioxide: Displaces oxygen, causes drowsiness

Always cut power to nearby pilot lights before investigating. Switch on hood fans or open doors for ventilation. If you smell strong chemical odors or feel dizzy, evacuate immediately and call professionals. Keep a portable gas detector on hand if staff must inspect confined spaces. Never ignore these warning signs—chemical spills from wrong cleaning materials can make fumes even more dangerous.

Summary: Grease trap gases include toxic hydrogen sulfide (rotten egg smell), flammable methane, respiratory-irritating ammonia, and oxygen-displacing carbon dioxide—ventilate immediately if odors are strong and evacuate if you feel dizzy.

How often should I pump my grease trap?

Pump your grease trap every 1–3 months or when it reaches 25% full (measured from top to grease layer), whichever comes first. Regular pumping helps eliminate odors and prevents costly disasters.

Pumping frequency depends on usage (same guidelines apply for how often to pump grease interceptor systems):

- High-volume restaurants: Monthly pumping to stay safe

- Medium-volume kitchens: Every 2 months

- Light-use facilities: Quarterly

- Always pump at 25% full regardless of schedule

Skipping pumping leads to clogs in drains, foul odors that affect your property, and expensive emergency service calls. Proper maintenance is essentially your insurance against disasters that frequently occur when grease traps are neglected.

Summary: Most grease traps need pumping every 1–3 months based on volume (monthly for high-use, quarterly for light-use), but always pump when grease reaches 25% of trap capacity to prevent emergency repairs costing 10x more.

What chemicals can I use in my grease trap?

Use only enzyme-based cleaners or natural solutions like baking soda and vinegar as your safe grease trap cleaner. Never use bleach, caustic cleaners, or mix different chemicals that could create toxic spills.

Safe cleaning materials and solutions:

- Enzyme digesters (bacteria that eat grease naturally)

- Baking soda + vinegar (safe foaming cleaner)

- Hot water + dish soap

- Citrus-based degreasers

Dangerous combinations to avoid:

- Bleach + ammonia = toxic gas requiring evacuation

- Different brand cleaners = unpredictable chemical reactions

- Caustic chemicals = pipe damage that gets worse over time

Using wrong chemicals can cause emergencies that affect your entire property. Periodically review your cleaning process to ensure staff know which materials are safe.

Summary: Enzyme cleaners and natural solutions like baking soda/vinegar are safe for grease traps and actually help break down grease; avoid bleach which kills beneficial bacteria and never mix chemicals which can create toxic gases.

How much does grease trap maintenance cost?

Regular maintenance costs $200–400 every 1–3 months. Emergency repairs from disasters cost $500–50,000 depending on severity (2025 US averages).

Typical 2025 U.S. cost ranges:

- Preventive pumping: $200–400 (keeps trap working properly)

- Emergency pumping: $500–1,500 (when clogs develop suddenly)

- Major pipe repairs: $5,000–50,000 (when rot affects parking lot pipes)

- Business interruption: $1,000–5,000/day (during repairs)

Regular maintenance prevents 95% of emergencies and extends trap life by years. Here are tips to prepare: budget for quarterly service, keep emergency funds available, and track maintenance to spot problems that frequently develop over time.

Summary: Spending $200–400 on regular pumping every 1–3 months prevents emergency repairs costing $5,000–50,000, plus saves thousands in daily business interruption costs, protects your property from disasters, and extends your trap’s lifespan by years—essentially the best investment to stay safe.

What causes grease trap odors?

Grease trap odors come from bacteria breaking down trapped food particles and grease, releasing hydrogen sulfide and other gases. These odors develop when organic materials accumulate in trap compartments.

The smell develops through this process:

- Food particles and grease accumulate in each compartment

- Bacteria multiply and eat waste materials

- Decomposition releases smelly gases into the air

- Overfilled traps can’t contain odors, making problems worse

Poor ventilation, infrequent pumping, and mechanical failures (like dry P-traps) allow grease trap smells to spread throughout your property. This process occurs more quickly in warm weather when bacteria are more active.

Summary: Bacteria decomposing trapped grease and food particles create odorous gases like hydrogen sulfide—regular cleaning every 1–3 months and weekly enzyme treatments prevent this buildup, eliminate bad smells at the source, and keep your trap working properly to protect your family or staff.

When should I call a professional for my grease trap?

Call professionals immediately if sewage backs up, multiple drains won’t work, you smell gas (not grease), or see grease in unexpected places like parking lots.

Emergency signs requiring immediate help:

- Water backing up into sinks/floors

- Complete drainage failure

- Overwhelming chemical smells

- Visible grease outside trap area

- Gurgling from multiple fixtures

These indicate system failure beyond DIY fixes.

Summary: Multiple drain failures, sewage backups, gas odors, or grease appearing outside the trap indicate system failure requiring immediate professional service with specialized vacuum trucks and safety equipment within 24 hours.

Can I clean my own grease trap?

Basic maintenance like enzyme treatments and hot water flushes are safe DIY tasks, but leave pumping and repairs to licensed professionals with proper equipment. This approach helps you stay safe while maintaining your trap.

What you can do to rid your trap of minor issues:

- Daily hot water flushes to eliminate grease buildup

- Weekly enzyme treatments (bacterial solution)

- Visual inspections of accessible areas

- Preventive maintenance between professional cleanings

What requires professionals:

- Pumping (needs vacuum trucks and disposal permits)

- Internal repairs to damaged compartments

- Chemical spill cleanup from wrong materials

- Major clogs affecting multiple sinks and drains

Some municipalities require manifests or disposal records—check local grease trap ordinances before attempting any grease trap work. Professional cleaning makes the difference between a trap that works properly and one prone to disasters.

Summary: Handle daily hot water flushes and weekly enzyme treatments yourself to save money, but hire licensed professionals for pumping and repairs to ensure safety, proper disposal, compliance with regulations, and to avoid exposure to dangerous gases.

How do grease trap problems develop?

Grease trap problems develop over 13+ weeks: food particles accumulate (weeks 1–2), bacteria multiply causing odors (weeks 3–4), grease thickens affecting flow (weeks 5–8), clogs form (weeks 9–12), then emergencies occur. Understanding this process helps you prepare for maintenance.

This timeline shows typical progression in restaurant and family business settings:

- Weeks 1–2: Initial accumulation in compartments

- Weeks 3–4: First odors appear as bacteria eat waste

- Weeks 5–8: Drainage slows, affecting sink performance

- Weeks 9–12: Serious clogs develop in pipes and drains

- Week 13+: Emergency conditions require immediate pumping

Regular maintenance periodically interrupts this cycle, preventing disasters. Without intervention, problems get progressively worse until your trap stops working properly.

Summary: Grease trap failures follow a predictable 13-week pattern from initial food particle buildup to full emergency conditions—regular maintenance every 1–3 months interrupts this cycle and prevents costly disasters before week 9 when serious problems begin.

Complete Maintenance Summary

To prevent grease trap problems: flush with hot water nightly (60 seconds minimum), add enzyme digesters weekly (beneficial bacteria that eat grease), pump every 1–3 months or at 25% full, and never pour grease down drains or sinks. Address foul odors immediately with hot water mixed with high-grease-cutting dish soap, followed by baking soda and vinegar for persistent bad smells. Call professionals for sewage backups, multiple drain failures, gas odors (not just grease), or when grease appears outside the trap area (parking lot or exterior drains).

This comprehensive approach prevents 95% of emergencies, extends trap lifespan by 50%, reduces emergency repair costs from $5,000–50,000 to just $200–400 in regular maintenance, and keeps your kitchen safe, compliant, and odor-free year-round. Proper maintenance essentially eliminates disasters that frequently affect restaurant property and family businesses.

Need step-by-step troubleshooting tips? See our full Grease Trap Maintenance Guide for step-by-step grease trap cleaning procedures, video tutorials, and downloadable maintenance schedules to help you prepare for any situation.