Table of Contents

Opening Note: Why This Matters

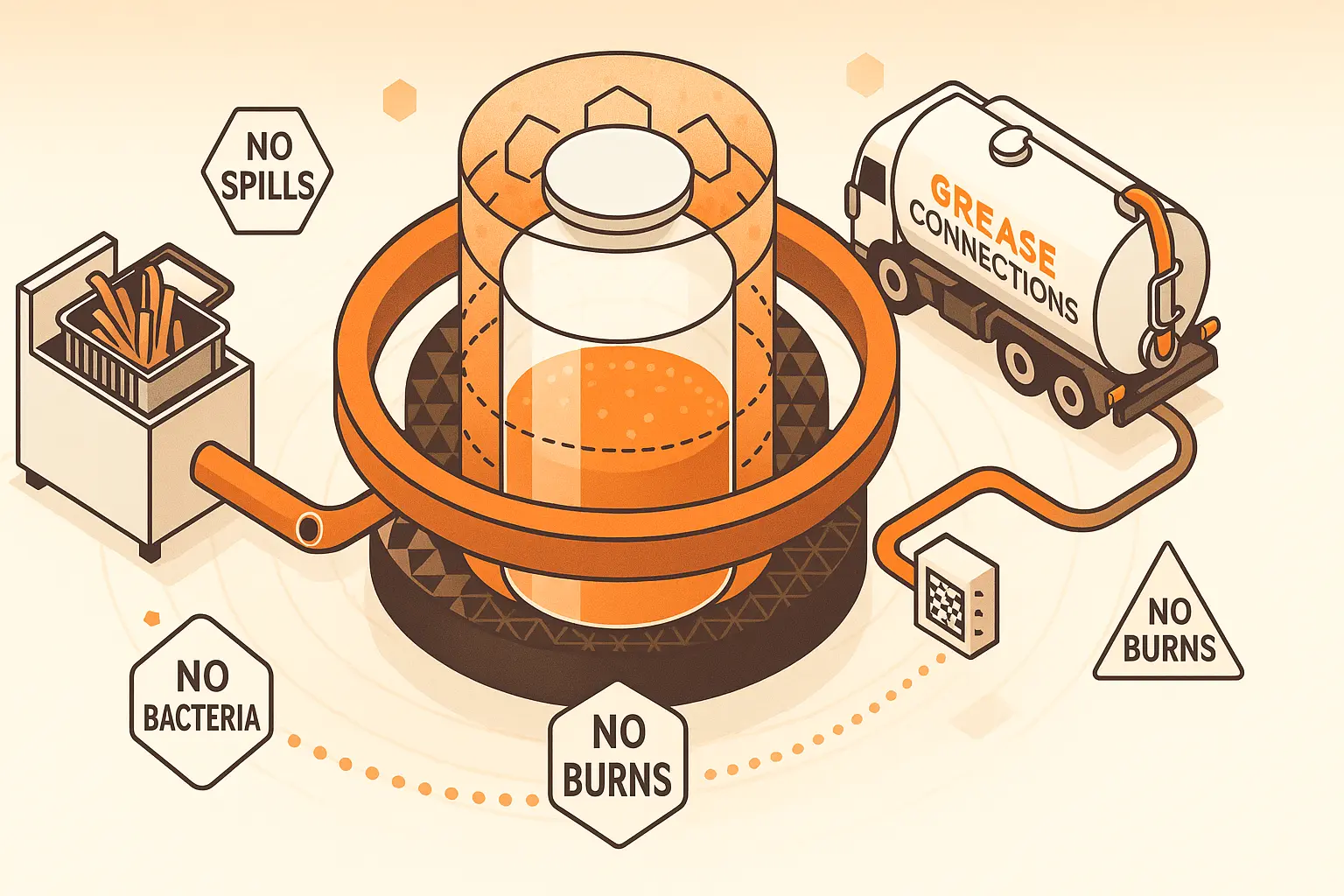

A single splash of fryer oil can spread bacteria, fuel a hood fire and sideline staff with burns. CDC cleaning guidance warns that moist, organic waste is a ready growth medium for pathogens. In healthcare kitchens where every meal touches vulnerable patients, traditional open barrels break three rules at once: they expose hot oil to air, invite spills on the floor and force staff to lift 350 degree liquid.

Florida, Georgia and New Jersey health inspectors now cross check those same steps against FDA Food Code waste provisions and Joint Commission infection control elements. The question becomes simple: Which collection system keeps oil, staff and patients safest? The answer, as new data and field results show, is the fully sealed, closed loop line that moves oil straight from fryer to indoor storage tank to a vacuum hose on the used collection company’s truck with no open pours, no carts in hallways, no second chance for microbes or fire.

Infection Control Rules That Shape Oil Handling

CDC’s environmental services playbook tells hospitals to pick equipment that can be sanitized, keeps waste covered and minimizes hand contact. FDA Food Code §5 501 adds that waste receptacles must be leak proof, pest proof and easy to clean. Joint Commission IC.02.02.01 extends the duty: hazardous kitchen waste must travel in sealed containers along a route that avoids patient areas.

Add NFPA 96 fire load limits on grease storage and you have a four agency checklist every hospital surveyor now carries. Any system that leaves oil in open tubs, tilt skillets or outdoor barrels fails at least one of those checkpoints. That has pushed many facilities toward semi or fully automated setups that cut touchpoints below CDC’s “hand hygiene breakpoint” and keep the pathway closed until the used collection company arrives.

Comparing the Options

Manual caddies, semi closed tote tanks and direct plumbed closed loop lines all exist on today’s market. The table shows how they score against infection control and safety markers documented by OSHA, NFPA and recent hospital audits.

| System Type | Sealed Path? | Surface Sanitized in line? | Weekly Burn/Slip Risk* | Meets Joint Commission IC waste element? |

|---|---|---|---|---|

| Manual Wheeled Caddy | No | No | High | Rarely |

| Semi Closed Tote w/ Wand | Partial | Tank washable | Medium | Sometimes |

| Closed Loop Direct Plumbed | Yes | Automatic flush option | Low | Yes |

Why Closed Loop Wins

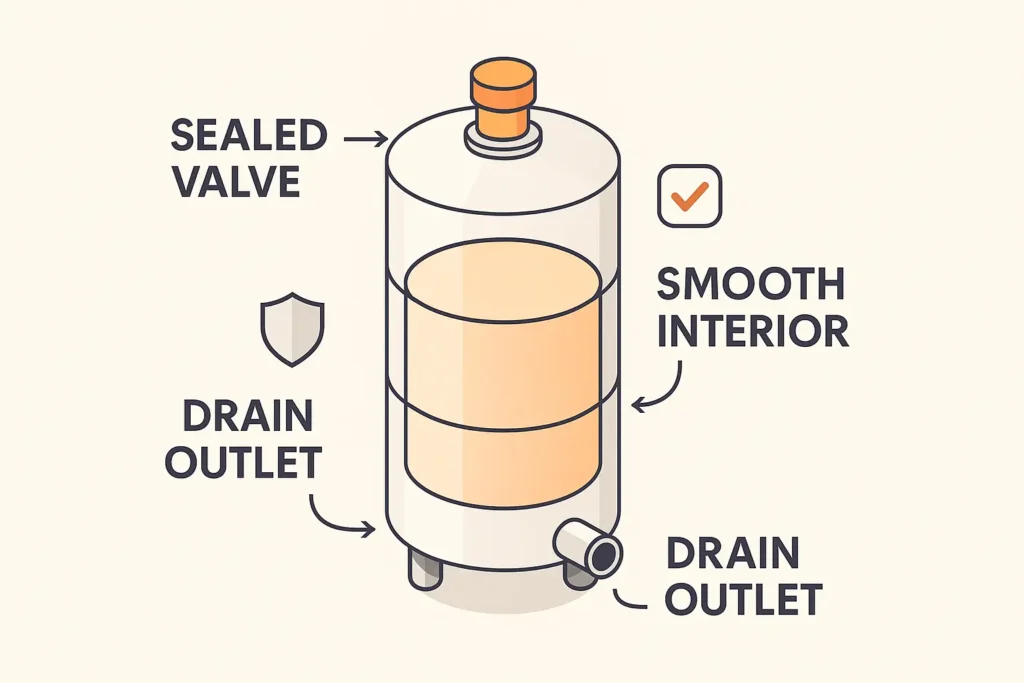

Closed loop lines keep oil under a sealed nitrogen blanket from fryer drain to stainless indoor tank. That barrier blocks aerobic bacteria growth noted in UNC’s infection prevention kitchen checklist and prevents slips the RTI study linked to 90% of oil burns. An inline filter captures crumbs that would otherwise decay, while the tank’s smooth interior meets CDC guidance for “easily cleaned” surfaces.

When the used collection company docks its hose, vacuum transfer keeps vapors out of hallways, an OSHA fix for confined space gas buildup in outdoor traps. NFPA 1 already tells inspectors that metal grease containers must be emptied or inspected weekly; a closed loop vendor’s telemetry log triggers pickups automatically, so compliance is hands free.

Implementation Blueprint for FL, GA & NJ Hospitals

Start with a joint walk through: food service, infection control and engineering teams map fryer locations to the nearest wall penetration. Next, a licensed plumber installs Schedule 40 lines with ½ inch fall, sloping away from the kitchen to an indoor 200 to 300 gallon tank sized for the facility’s average fry volume.

NFPA 96 clearance (18 in. from combustibles) and state plumbing codes apply. Florida AHCA env health officers, Georgia DPH inspectors and New Jersey DEP FOG regulators all accept closed loop tanks because the oil never touches a drain. Finally, write the process into the HACCP plan: the only staff task becomes flipping a drain valve lever twice daily.

Compliance & Survey

Surveyors ask three things: “Show me your policy, your logs and your maintenance record.” A cloud dashboard from the closed loop vendor exports CSV files that list drain times, volumes and automatic pickup dates, perfect for Joint Commission eTrac upload. Weekly visual checks, signed by food service leads, satisfy FDA Food Code §8 401 self inspection, while quarterly filter swaps meet NFPA 96 11.6.2 cleaning intervals. Because the line stays sealed, infection control practitioners log “no patient exposure risk” under IC.02.01.01.

Cost Benefit Story

When Tampa General switched to sealed lines it reported zero burn claims in 12 months and recouped installation cost through 12¢/lb bio credit on every pickup. An Atlanta system showed 30 minutes saved per shift and a 90% drop in slip and fall payouts. OSHA’s bulletin puts the average grease trap injury at $48,000 in medical and lost time costs, dwarfing the monthly lease of a closed loop system. Cleaner fryer exhaust also cut hood scraping from monthly to quarterly, aligning with ABS hospital equipment sanitization standards.

Looking Ahead: Biofuel & ESG Wins

Used oil is now a preferred feedstock for low carbon aviation and truck fuels. Hospitals in Penang even upcycle a fraction into antimicrobial soap for ward cleaning. Closed loop collection keeps the chain of custody airtight, which certifiers like ISCC require for Scope 3 emissions credits. Adding QR coded manifests lets sustainability officers prove diversion from sewer to renewable fuel, a data point that helped one New Jersey network earn Climate Ready Campus grants last spring.

Key Takeaways

Sealed, touch free closed loop systems hit every infection control checkbox: leak proof, easy clean, zero contact, fire safe and fully trackable. They replace risky lifts with a one hand valve, slash staff injuries and turn fryer waste into a compliance asset. In Florida, Georgia and New Jersey; where inspectors cite FDA, CDC, Joint Commission and NFPA rules; closed loop is now the clear path to a perfect kitchen score and greener operations.