Table of Contents

Why Yesterday’s Fry Oil Matters to Tomorrow’s Flight

America’s deep fryers throw off nearly three billion pounds of used cooking oil each year: enough carbon rich liquid to fly coast to coast ten million times when upgraded to sustainable aviation fuel (SAF). Today’s SAF, made mostly through the Hydroprocessed Esters and Fatty Acids (HEFA) pathway, can cut lifecycle greenhouse gas emissions by up to 80% compared with fossil Jet A.

The magic is “drop in” compatibility: airports, engines, and fuel trucks stay the same, slashing adoption costs. That is why major carriers already blend HEFA on commercial routes, and why federal policy targets three billion gallons of SAF by 2030. The race is on, and the feedstock is already in your kitchen.

HEFA in Plain English: The Kitchen Oil to Jet Fuel Makeover

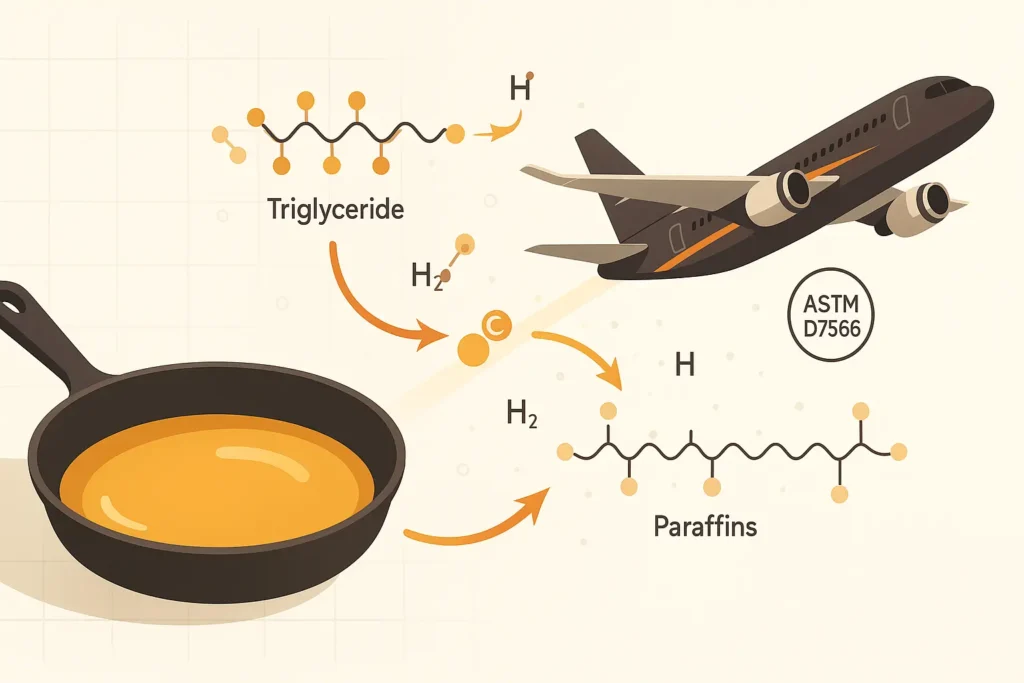

HEFA starts with any triglyceride: think fryer grease, tallow, or distillers corn oil. After pretreatment removes water and metals, the oil meets high pressure hydrogen in a reactor approved by ASTM D7566 Annex 2 back in 2011.

Oxygen leaves as water, turning fats into straight n paraffins. A second reactor cracks and bends those chains until they match jet fuel length, a trick that resembles renewable diesel production but runs hotter and longer for aviation specs. HEFA already powers over 95% of all SAF flights to date, because restaurants, renderers, and seed crushers can supply waste lipids today: no futuristic feedstock required.

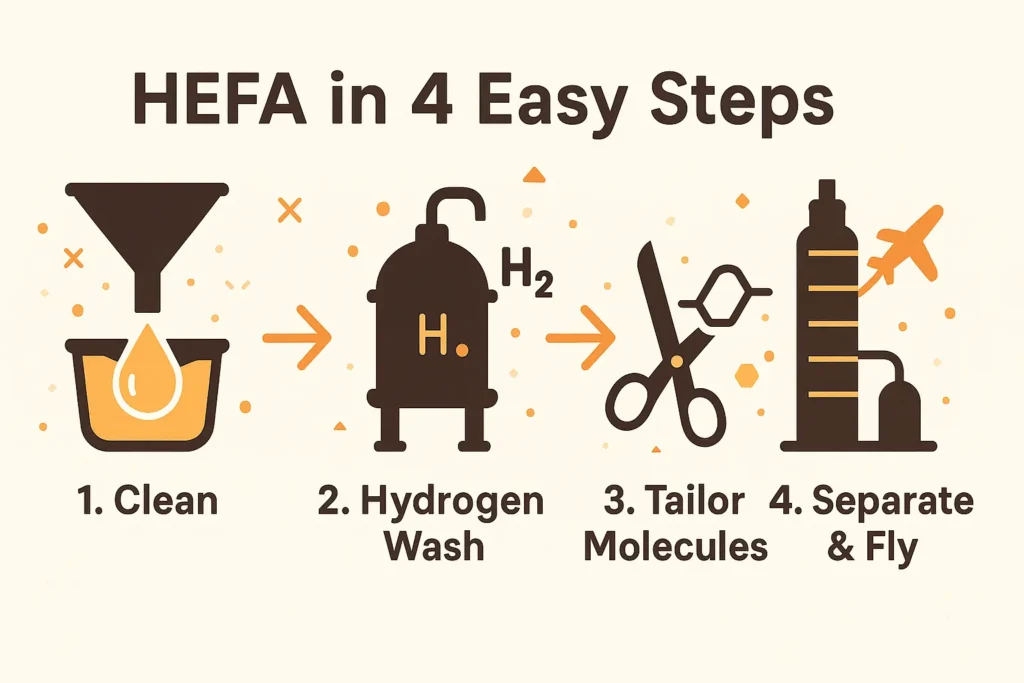

Step by Step Chemistry: From Fries to Flight

- Hydrodeoxygenation (HDO) strips oxygen with a sulfided NiMo or CoMo catalyst, releasing water and propane.

- Decarboxylation/Decarbonylation (DCO) can be tuned to save hydrogen at the cost of a little carbon loss, a key refinery trade off.

- Hydrocracking clips long chains into the C8 to C16 sweet spot for jet fuel, while hydroisomerization adds branches that improve cold flow properties, both detailed in ICAO’s HEFA process map.

- A final fractionation distills the mix so density, flash point, and aromatics sit safely inside ASTM limits.

Every reaction takes place in equipment most U.S. refineries already own, speeding scale up and keeping costs in check.

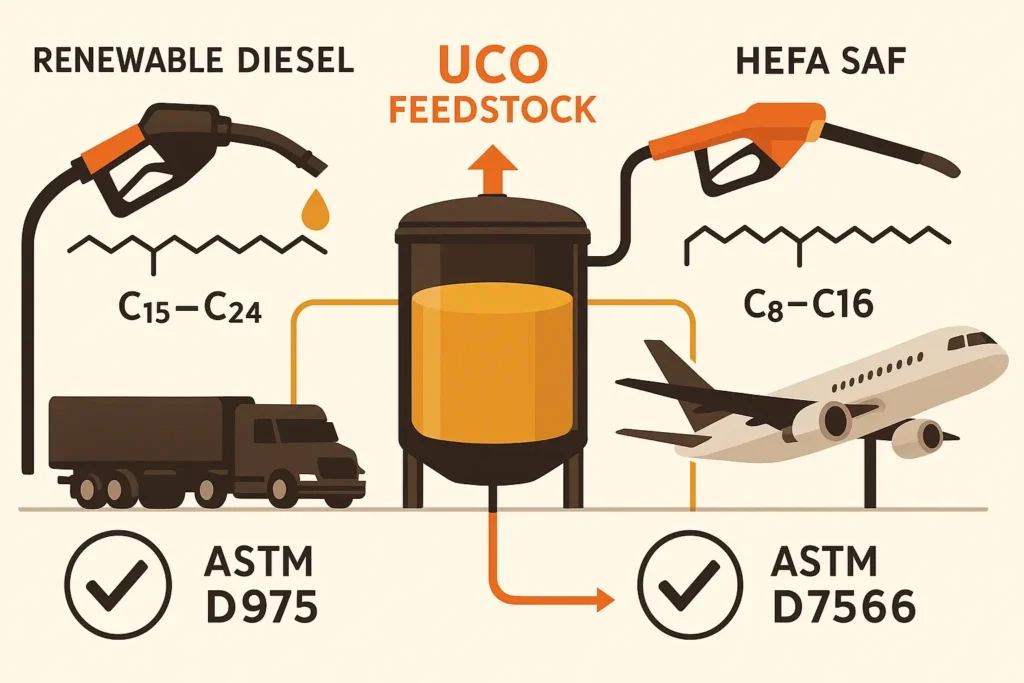

Diesel or Jet? How One Plant Makes Two Fuels

| Attribute | Renewable Diesel (RD) | HEFA SAF (HEFA SPK) |

|---|---|---|

| Main Cut | C15 to C24 diesel range | C8 to C16 jet range |

| Extra Cracking/Isomerization | Not required | Required |

| ASTM Spec | D975 | D7566 Annex 2 |

| Blend Limit | 100% drop in | 50% with Jet A |

| End Use | Road fleets | Aviation |

Renewable diesel plants can switch valves and catalysts to chase the higher value jet market, but doing so lowers yield per barrel, which helps explain why RD volumes still dwarf SAF. Airlines pay a premium for the lighter cut; fleets like the heavier one. Knowing the difference helps restaurants choose the right collection partner.

Feedstock Reality Check: Will There Be Enough Grease?

U.S. capacity could surge fourteen fold this year if announced HEFA projects deliver, says the Energy Information Administration. Analysts at the University of Illinois note that five renewable diesel plants already have SAF conversion lines totaling 1.5 billion gallons per year by 2026. Yet SkyNRG and ICF warn of a “HEFA tipping point” where waste oil supply tightens and prices rise.

That makes used cooking oil from U.S. restaurants mission critical. A single quick service site can yield 1,000 to 1,500 gallons of grease annually, enough for fifty cross country passenger legs after upgrading, according to Grease Connections 2025 industry report.

What This Means for Your Restaurant

Every gallon of fryer oil you hand to a reliable used collection company can travel farther and earn more than ever before. Grease now fetches renewable fuel credits and SAF tax incentives, lifting its value well above yellow grease’s historic commodity price.

When you document chain of custody data, airlines can claim the carbon reduction, and you can tell customers their favorite wings help decarbonize flight. That story boosts brand image and can satisfy new municipal waste diversion rules popping up from Atlanta to Miami. Ready to lock in? Grease Connections offers transparent volume tracking and the option to direct your oil to local SAF plants, keeping benefits and planes close to home.

Grease Connections’ Closed Loop Advantage

Grease Connections was built around the HEFA pathway. Our teams collect, pretreat, and ship your oil straight to partner refineries, closing the circle from fryer to flight. That means no speculative middlemen and verifiable lifecycle data you can share with auditors.