Table of Contents

Why Proper Oil Storage Sets the Tone for Every Inspection

Used cooking oil feels like yesterday’s problem until an inspector lifts the lid on your drum and starts snapping photos. At that moment the conversation shifts from food to safety, fire risk, and municipal code. In many states a single spill or unlabeled container triggers a critical violation and a re‑inspection fee that wipes out a full weekend’s revenue.

Regulators care because hot grease can flash near 600 °F, flow under doors, and turn a small leak into a building‑wide hazard. Rancid oil attracts pests, stains asphalt, and creates fatbergs that block city sewers. When a crew finds a blockage they trace it back and demand manifests; every gallon you cannot account for becomes a fine.

Proper storage is step one in restaurant grease disposal. A sealed, purpose‑built container keeps oxygen and rainwater out, reduces fire load, and gives your hauler a clean pump port. Equally important, it shows inspectors you run a disciplined shop. They know the difference between a battered 35 lb shortening cube and a UL‑rated 55‑gallon black drum with a locking ring. Choose the second and you signal professionalism before a single word is spoken.

This guide walks you through the routine our clients follow to earn “no findings” during fire, health, and EPA visits. It starts with a container sized to your nightly volume, continues with cooling and filtering practices that preserve the oil’s recycling value, and ends with a pickup that happens so smoothly your team barely notices. By the end, you will know exactly what inspectors expect, what recyclers pay for, and how a few minutes of daily habit can protect your kitchen’s reputation.

Pick a Container Your Health Inspector Trusts

Pick a container your health inspector trusts, your cooks can use without spills, and your hauler can empty in under 5 minutes. That means looking beyond the free plastic barrel your grease company left behind 10 years ago. Start by measuring nightly fryer turnover: a pair of 50‑lb fryers emptied after service yields roughly 10 gal of used oil. Over a 7‑day interval that becomes 70 gal. A container should hold at least 25 percent more than your peak weekly volume so you never scramble on holiday weekends.

For most independents the 70 gal square caddy on wheels is the sweet spot. Its low profile slides under a hooded fryer dump station, the hinged lid holds vapors in, and the drawbar lets staff roll it to the loading dock without lifting. If you serve high‑volume fried chicken, step up to the 140‑gal rectangular tank with a locking lid; the extra headroom prevents late‑night overflows that soak asphalt and invite rodents. Multi‑unit operations with shuttle pumps lean on the 300‑gal larger rectangular tank on wheels, or the tall slim automated system that pairs a pump cart and hose for hands‑off transfer.

No matter the size, demand double‑walled steel or heavy‑gauge poly tested to UL 80. Heat‑resistant gaskets prevent flash fires when oil is still 350 °F. A front sight glass lets staff confirm capacity at a glance, avoiding the “just dump it in the drain” temptation. Ask for models that accept both gravity dump and quick‑connect pump‑out; that flexibility cuts hauler downtime and keeps your disposal fee low.

Label the unit “Used Cooking Oil Only” in 4‑inch letters, log the install date, and mark the maximum fill line. Those three touches alone resolve 90 percent of wording inspectors use when they write up storage deficiencies.

Let the Oil Cool, Strain, and Settle; Your Future Self Will Thank You

Letting oil cool, strain, and settle sounds obvious until a rush hits and someone tips a 35‑lb fry pot straight into the caddy. That shortcut drives up used fryer oil pickup costs because haulers must process water, crumbs, and charred batter you could have removed for free. Worse, pouring oil over 300 °F into a closed drum can ignite vapors.

The target temperature is below 140 °F; cool enough to handle safely, hot enough to stay liquid. Most fryers reach that point 45 minutes after power‑down. Post‑service, crack the drain valve, let oil pass through the fryer’s crumb screen, then guide it through a fine‑mesh cone filter before it hits your storage tank. If your fryer lacks an internal screen, use a stainless pot with a reusable 100 micron bag. The whole routine takes 4 minutes and removes up to 80 percent of solids that would otherwise sink to the tank bottom.

After transfer, close the lid and give the oil a day to settle. Sediment drops to the bottom, leaving cleaner oil on top that pumps faster and clogs hoses less. Train staff never to stir the tank; agitation mixes sediment back in and resets the clock. If condensation forms on the hood, wipe it before it drips; water turns hot oil into a mini‑geyser.

Weekly to do: open the rear drain and bleed off the sludge layer into a 5‑gal bucket. The thick paste of breading and starch belongs in the solid‑waste dumpster, not in your hauler’s tanker. Cleaner oil means bigger rebates and a smiling driver. Keep a kitchen timer near the fryer chute as a cue; when it buzzes, staff know the cooling window is over and safe transfer can begin without guesswork.

Grease Connections

Keep the Storage Zone Clean, Secure, and Weather Proof

An oil tank is only as safe as the corner where it lives. Choose a zone with three qualities: level ground, overhead protection, and clear access for a vacuum truck hose no longer than 50 ft. A covered dock or fenced pad beside the grease interceptor keeps rain out and inspectors calm. If you must store outdoors, set the container on a spill‑proof pallet or a concrete pad with 2 in berms. That captures drips before they reach the storm drain and counts as “secondary containment” under most local ordinances.

Security matters too. Used cooking oil fetches real money on the black market; a 300 gal tank can hold $500 in biofuel feedstock on a busy week. Bolt the tank to anchor points, install a lid hasp, and aim a motion‑activated light at the pad. Theft drops by 90 percent when cameras are visible. Inside, place floor mats around the funnel to grip grease‑soaked shoes and cut slip claims.

Post a simple SOP at eye level: cool, filter, pour, wipe, close. One laminated sheet reduces training time for new hires and gives inspectors proof of written procedure. Keep an MSDS for used cooking oil in your safety binder; yes, even though it is “just food.” Fire marshals ask for it because grease is a Class K fuel.

Once a month, degrease the exterior walls with citrus solvent, inspect gaskets for cracks, and confirm the sight glass is clear. The 10‑minute ritual prevents buildup that hides leaks and breeds fruit flies. Should your landlord require proof of maintenance, snap a date‑stamped photo after each cleaning and file it; that tiny habit can resolve disputes years later.

Give Your Hauler a Friction Free Pickup Day

The fastest way to sour a hauler relationship is to make their driver hunt for your tank. Send a standing calendar invite that reminds the closing manager to roll the caddy to the dock 30 minutes before the window. If the container stays put outdoors, unlock the gate and clear parked cars that block the vacuum truck. Drivers appreciate shaved minutes and reward punctual kitchens with early slots on holiday weekends.

Before the truck backs in, verify the oil level is below the “max fill” stripe. An overfilled drum foams when the hose stirs it, coating asphalt and earning you a cleanup bill. Skim floating crumbs with a wire strainer and tighten the lid. These gestures tell the driver the load is clean, which often translates into better rebate pricing because the product needs less filtering downstream.

When the pump switches on, record the beginning and ending gallon counts shown on the truck meter. Cross check that figure against your fryer log: last week’s oil‑out should roughly equal this week’s transfer‑in plus any top‑ups of fresh jugs. Discrepancies larger than 10 percent hint at theft or sloppy handling. Most haulers email a digital bill of lading within hours; save it in a “Grease” folder for instant retrieval during audits.

Finally, wipe drips from the hose coupler, relock the lid, and reset the spill berm if you moved it. A quick sweep with absorbent pads keeps the pad stain‑free and deters pests. The whole hand‑off, done right, takes 8 minutes and sends you back to prepping mise en place before the lunch rush. Consistency is key; when every Tuesday looks the same, staff stop improvising and the operation runs on rails, leaving you free to focus on guests instead of garbage.

Final Checklist: Stay Audit‑Ready, Save on Fees, and Build a Greener Brand

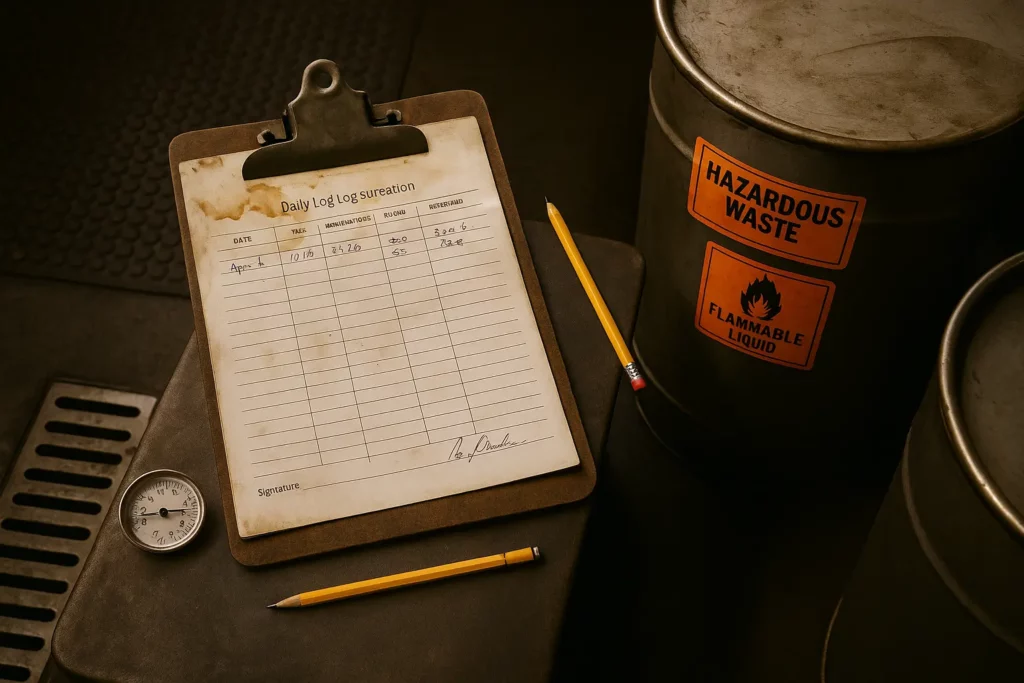

A clean close out routine ties every step together and keeps you audit‑ready. Begin with a daily two‑line log: temperature at transfer and gallons moved. The numbers prove you cooled oil below flash‑point and tracked volume. Add a weekly tick box for sludge bleed‑off and a monthly box for exterior cleaning. Inspectors love concise forms; they hate binders stuffed with unread SOPs. Keep the sheet on a clipboard at the tank, not in an office drawer.

Next, review your hauler contract. It should state pickup frequency, rebate formula tied to commodity markets, and liability coverage for spills. Confirm they provide certificates of recycling within 24 hours so you can show proof during surprise visits. If your business spans several sites, standardize containers and paperwork across the chain; uniformity simplifies training and lets regional managers spot anomalies at a glance.

Don’t ignore the marketing upside. Guests increasingly ask about sustainability. A brief menu note or social post explaining that you recycle 100 percent of fryer oil into biodiesel turns compliance into brand equity. Some operators wrap the tank in vinyl carrying the same message; the dock shifts from a back‑of‑house mess to a micro billboard.

Finally, test your fire‑suppression and spill‑containment plans twice a year. Simulate a hose rupture, time how long it takes staff to deploy absorbent booms, and document the drill. The exercise reinforces habits and demonstrates diligence if an incident reaches court. Remember: routine builds resilience. When turnover spikes during festival season or a new location comes online, the same disciplined framework scales without drama or surprise costs. Treat used cooking oil as a resource, not waste, and every inspector, hauler, and guest will notice.