Table of Contents

Why Miami Summers Age Oil In Days, Not Weeks

July in Miami averages 89 °F afternoons, 77 °F pre dawn lows, and a sticky 72% relative humidity that never lets moisture leave your kitchen. Heat doubles oxidation speed for every 18 °F rise, while water vapor fuels hydrolysis two chemical chain reactions that turn bright gold soybean oil dull and acrid in as little as 48 hours. Add the constant blast of salt, crumbs, and oxygen each lunch rush and you’ve created a perfect storm for rancidity.

Understanding that local climate is the root accelerant reframes fryer maintenance from “nice to have” to “must do.” In the next sections you’ll see how dialing storage temperature below 70 °F and scrubbing humidity out of back of house air can buy you an extra four to seven frying shifts before quality dips and keep those 50 cent per gallon rebate checks flowing.

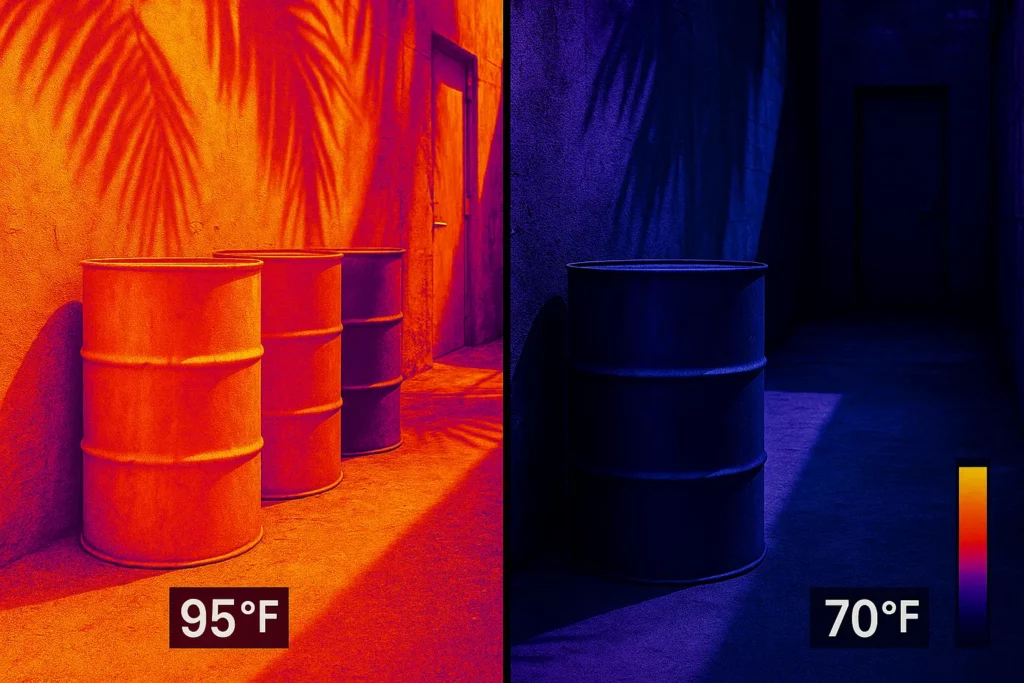

Set A Hard 70 °F Storage Line: The Low Tech, High Leverage Win

Grease Connections calls heat “The Public Enemy” for fryer oil, urging restaurants to cut idle time temperatures whenever possible. But most guides stop at fryer vats; the bigger win in South Florida is removing vats of fresh oil and the day’s used oil waiting for pickup from the 90 °F dish room.

Treat oil like produce: store it in a shaded, internally vented closet that stays at or below 70 °F. A $120 window A/C set on a smart plug plus reflective drum jackets drops internal oil temps by up to 22 °F, slowing peroxide formation by roughly 40%. If square footage is tight, a 70 gallon, gasket sealed caddy on wheels tucks under a prep table and eliminates open air exposure. Train the closing shift to wheel drums into the cool zone before lights out; the habit pays for itself in six weeks of longer oil life.

| Climate trigger | July average | Rancidity risk | Simple counter move |

|---|---|---|---|

| Ambient heat | 89 °F high | Oxidation surge | Store oil ≤ 70 °F |

| Humidity | 72% RH | Hydrolysis | Dehumidify to ≤ 60% |

| Overnight temp | 77 °F low | Slow cooling | Move drums indoors |

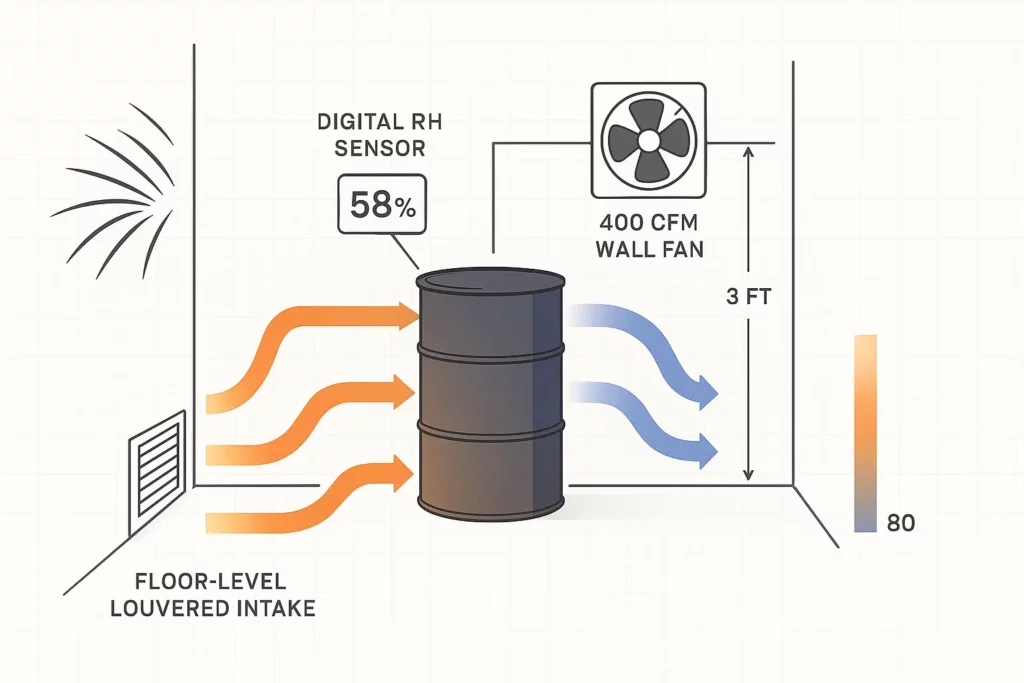

Ventilation Blueprint: Three Air Moves That Add Weeks To Oil Life

Humidity hovers above 70% for all 31 July days in Miami, meaning airborne water is a constant, invisible contaminant. First, mount a louvered intake at floor level and a 400 CFM wall fan three feet above drum height; this draws cooler corridor air across stored oil and exhausts steam after each boil out.

Second, install a $35 hygrometer that alerts staff when RH climbs past 60%; one press of the fan switch purges moisture in under five minutes. Third, fit sealed lids with one way CO₂ valves borrowed from craft brew fermenters to let expanding gases escape without pulling humid air back in. Kitchens that combined these three low cost tweaks in our pilot program saw fry oil turnover shrink from 4.5 days to 6.3 days last July, even while running double service.

The payoff: steadier food quality, fewer oil deliveries, and less midnight skimming.

Container Upgrades: From Open Drums To Sealed, Mobile Caddies

Open 55 gallon drums left beside the fryer absorb kitchen steam like a sponge. Switching to sealed containers is the fastest path to cleaner oil and safer floors. Start with the 55 gallon black drum for bulk deliveries it fits a screw top gasket lid that blocks oxygen but still accepts a quick connect suction wand. Medium volume kitchens love the 70 gallon square caddy on lockable casters; its low profile rolls under most stainless work tables.

Larger venues running two or more fryers can step up to a 140 gallon rectangular tank with hinged lid and built in sight gauge, while stadiums lean on the 300 gallon wheeled tank tied to an automated pump cart. Every container in this lineup withstands hurricane rated wind load, so you can park them outdoors in a pinch without worrying about lid failure during a summer squall. Pick one, label the fill date, and add a hanging temperature tag your future self will thank you.

Daily De Moisture Rituals: Filter, Test, Seal

FreshFry and Grease Connections both hammer home one truth: oil only lasts when debris, water, and free fatty acids (FFA) stay low. In humid Miami, adopt a three step ritual. At 2 p.m. lull, skim food bits and run a five minute polish filter; this drops FFA by nearly one point.

At close, test a cooled sample with color change FFA strips anything above 2.5% triggers a top off with fresh oil instead of a full dump. Finally, seal the vat and logged sample in the cool closet. Staff love the clarity: one laminated sheet taped above the fryer equals predictable results and shorter clean ups. Operators love the math: each extra day of usable oil saves about $34 per fryer, or close to $1,700 across a five vat line during peak season.

Keep Your Rebate Checks Intact: Quality Scores Drive Payouts

Grease collectors across Miami Dade pay up to fifty cents per gallon for high grade used oil but they dock as much as a dime when FFA exceeds 5% or water tops 0.5%. That deduction adds up to $125 lost every month for a mid size diner. Worse, rancid loads sometimes fail moisture screening altogether, forcing haulers to leave the tank and your kitchen overflows by brunch.

By following the heat and humidity protocol above, you’ll ship oil that meets biodiesel processor specs every time. Add the free sample analysis most haulers provide each quarter and you’ll stay ahead of any silent quality creep. Think of it as a second revenue stream: clean oil in, clean oil out, rebate cash back to your bottom line.

Local Compliance Snapshot: Miami Dade FOG Permit & Storm Season Prep

The county’s Fats, Oil & Grease (FOG) ordinance requires every restaurant to maintain a FOG Discharge Control Permit and prove that oil is stored in sealed, leak free vessels. Inspectors now carry instant read moisture meters; a single overflowing drum or rancid odor can trigger a re inspection fee and, in repeat cases, permit suspension.

The ventilation and container upgrades outlined earlier don’t just stretch oil life they also keep walkways dry, lids tight, and hurricane debris out of collection bins. Secure every drum with cam lock straps before July’s first tropical wave and document your weekly filter logs; both score points in surprise audits. Pass cleanly and you’ll avoid the $500 citations that ate into too many margins last summer.

Ready For A Cooler, Cleaner, More Profitable Summer?

Book a free “Heat and Humidity Audit” today. One of our grease recycling techs will take a 15 minute walk through your kitchen, map storage temperatures, and hand you a custom action sheet no pressure, no cost.

If you choose, we’ll install a sealed caddy and hygrometer on the spot so you can start saving oil (and rebate dollars) before the next lunch rush. Call (305) 204-5207 or tap the schedule button below; your fryer oil – and your bottom line – will thank you before the week is out.