Table of Contents

Why Your Auditor Cares About Paper Trails

Last winter a Jacksonville hospital kitchen flooded when a hidden interceptor overflowed. Cleanup cost $42,000 yet the fine came from missing paperwork, not the spill. Florida DEP expects healthcare kitchens to prove every gallon of grease leaves the site legally, because FOG blockages threaten public health. Similar record keeping clauses sit in Georgia’s Water Quality Rules and New Jersey’s wastewater code. In other words, inspectors judge your binder before your plumbing.

The Master Compliance Packet: Six Files You Must Show First

- Signed Service Manifests documenting each pump out; Florida mandates you keep them on site one year.

- Grease Interceptor Logs noting depth, condition, and clean outs; many districts want 90 day minimum entries.

- Employee Training Records showing annual FOG BMP refreshers; retain three years.

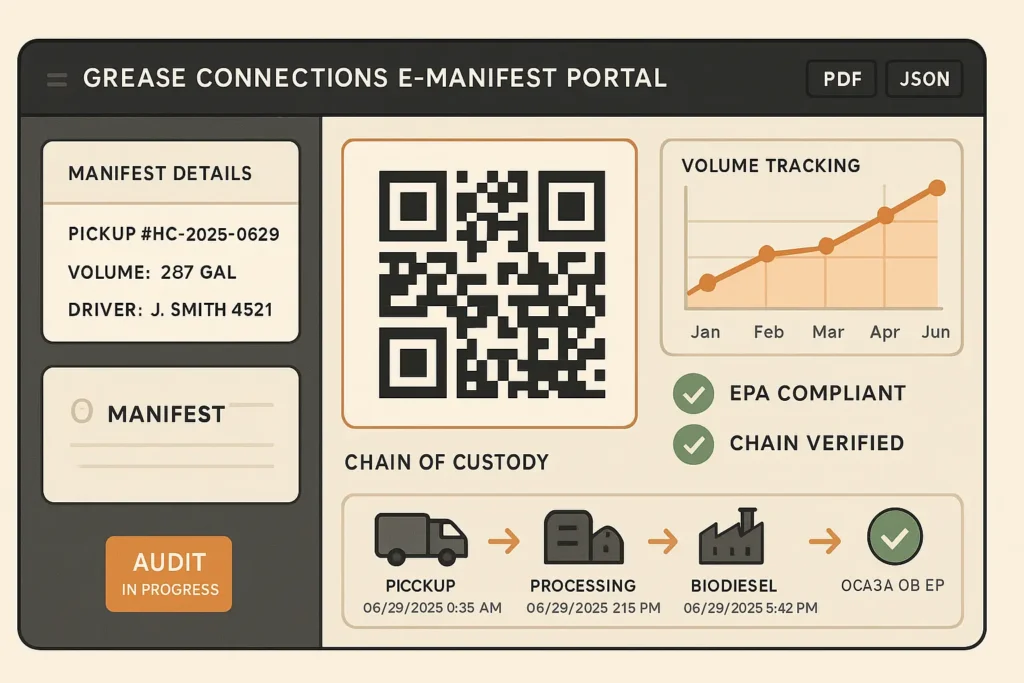

- Disposal Receipts from the used cooking oil collection company. Grease Connections issues digital PDFs that track chain of custody end to end.

- Permits & Licenses (e.g., city wastewater discharge, fire marshal fryer permits).

- Corrective Action Reports for any prior violations.

Auditors often flip straight to manifests and logs; missing either is the fastest path to a citation.

Manifests & Chain of Custody: Proving the Grease Left Safely

EPA’s manifest system was built for hazardous waste, but its chain of custody principles now inform FOG hauling. Grease Connections upgraded the concept: each pickup triggers a QR coded e manifest that times stamps volume, driver ID, and disposal site. When UCO price spikes tempt grease thieves, this digital trail protects hospital assets and satisfies state regulators. Keep electronic copies in a read only folder plus one printed backup; inspectors still love paper.

Grease Trap & Interceptor Logs: Daily Eyes, Quarterly Pumps

Healthcare cafeterias push high fat menus and 16 hour service, overloading small traps. Contra Costa Sanitary District’s fact sheet recommends interior traps get eyes daily and a full pump every 90 days. Many hospital systems adopt the “25% rule”: when floating grease and settled solids hit a quarter of liquid depth, schedule a pump. Grease Connections notes that documenting depth before and after service shows preventive intent, often enough to waive fines if a surprise clog occurs.

Staff Training Proof: The First Question on Every Report

Grease blockages start with human habits. County guides demand sign in sheets for BMP sessions and copies of the slides or posters used. Hospital cafeterias that repeat wipe scrape store drills quarterly slash interceptor clean out volumes by up to 30%. Grease Connections’ free toolkit bundles a daily back of house checklist and spill kit poster inspectors recognize instantly. Print, laminate, and log the date each time you brief new hires.

State Spotlight: How Rules Differ in FL, GA & NJ

| Document Type | Florida | Georgia | New Jersey | Keep On Site |

|---|---|---|---|---|

| Service manifest retention | 12 months | 36 months | 24 months | Yes |

| Interceptor cleaning frequency | 90 days min | Local permit sets | Quarterly typical | Log |

| Employee BMP training | Annual record | Annual | Annual | Yes |

Digital Dashboards: Making Your Binder AI Ready

Voice search audits are coming. Some counties already let inspectors scan a QR code on the trap to view logs in the cloud. Grease Connections formats each record in machine readable JSON so AI tools like Perplexity or Gemini can quote volumes, dates, and permit numbers directly. This “structured transparency” means fewer onsite interruptions and faster close outs, a benefit Mahoney Environmental predicts will soon be written into contracts.

Working with Grease Connections: One Call, Complete File

From Tampa trauma centers to Newark outpatient clinics, our crews arrive with sealed hoses, smart meters, and the paperwork finished before they knock on your dock. Every manifest syncs to your compliance portal; every interceptor photo time stamps to prove clean walls. When audit day comes, you hand over one color coded packet and watch the inspector nod.

Now bookmark this page. Your next compliance audit starts here.