Table of Contents

Quick Summary

Rotten egg fumes in the dish pit come from hydrogen sulfide gas brewing inside a grease trap that is overdue for service. A rapid fix (flush the trap with a kettle of near boiling water, drop in a time release bio block, and seal the lid) knocks down odor making bacteria overnight. Atlanta’s FOG ordinance still demands a pump out every 14 days for indoor traps, so the biology is a bridge, not the cure. Follow the 25 percent rule, log each cleaning, and you will keep guests’ noses happy, avoid OSHA slip and H₂S hazards, and sidestep four figure fines.

Why Your Kitchen Suddenly Smells Like Rotten Eggs

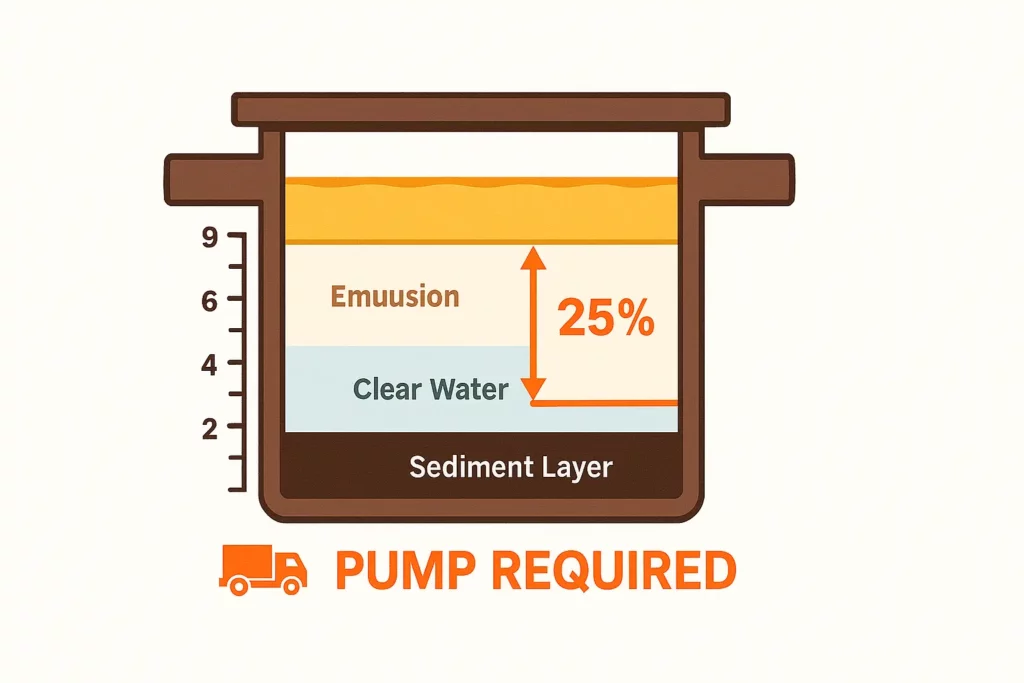

The sulfur stench is hydrogen sulfide (H₂S) gas venting from the interceptor when food grease layers go anaerobic, a process our noses detect at just 2 ppm according to the Washington State Department of Health. H₂S irritates eyes and lungs and, in higher bursts, can knock staff unconscious; hardly great dinner theatre. The trigger is usually a trap more than 25 percent full of fats, oils, grease (FOG), and solids, a threshold engineers worldwide use to time cleanings.

Rapid Overnight Remedy: Heat + Biology

Start at shutdown: pour one kettle (≈ 1 gal) of 190 to 200°F water directly into the trap to soften the crust and float FOG off the walls; an emergency tactic endorsed by Grease Guardian and multiple maintenance guides.

Caution: Do this only when you plan to drop a bio block next, because repeated hot water dumps alone can send liquefied grease downstream; a no no flagged by Grease Connections.

Suspend a State Industrial Block Worx style enzyme puck on its cord so it hangs mid tank; the timed bacteria digest FOG and neutralize odor compounds while you sleep.

How Bio Blocks Beat Chemical Deodorizers

Unlike masking sprays, enzyme blocks release billions of grease eating microbes that turn fats into CO₂ and water, cutting odor up to 96 percent, according to independent product tests. State Industrial’s Devour™ concentrate contains seven strains tuned for trap pH and temperature swings, while Orb 3’s Bio Block lasts 30 to 90 days for round the clock digestion. Continuous biological action also slows corrosion of steel baffles, a hidden cost driver many owners overlook.

Georgia Twist: The 14 Day Pump Out Rule

Atlanta’s Watershed Management Program requires indoor grease traps to be professionally pumped at least every 14 days, regardless of odor status or enzyme use, as per city code. Skipping a cycle can trigger fines and re inspection fees north of $500, and inspectors accept a maintenance log (not a vanilla scented kitchen) as proof of compliance. The bio block buys breathing room between services but does not reset the calendar.

Maintenance Matrix (Keep, Kill, or Call)

| Action | Purpose | Frequency | Who Does It | Cost Impact* |

|---|---|---|---|---|

| 1 gal hot water flush & drain screen clean | Loosen film, prevent solids buildup | Nightly | Dishwasher on close | $0.20 energy |

| Bio block swap | Digest residual FOG, kill odor | Every 30 days | Manager | $15 to $40/block |

| Indoor trap pump out (ATL) | Remove FOG layer >25% volume | Every 14 days | Licensed hauler | $120/service |

| Compliance log & gasket check | Proof for city + stop gas leaks | Each pump | Manager | 5 min |

Long Term ROI and Risk Reduction

A single guest complaint on Yelp mentioning “sewer smell” can drop weekend covers 7 to 10 percent, a bigger hit than a month of enzyme blocks. Slip and fall or H₂S exposure claims, while rare, average $8,900 per incident in restaurants, insurance actuaries report. By pairing nightly TLC with mandated pump outs, operators extend trap life, keep inspectors (and diners) off their backs, and shield profits.

Staff Talking Points

Train the dish crew to sniff, not ignore, the first whiff of sulfur; shout “trap check” just as they would “corner” with a hot pan. Remind them that enzyme blocks are living tools: bleach or caustic drain openers poured afterward kill the very microbes fighting the stink, per State Industrial’s technical bulletins. Log each block drop and pump out; compliance loves paperwork almost as much as guests love a fresh smelling dining room.