Why Grease Traps Matter

Every commercial kitchen produces fats, oils, and grease (FOG). Left unchecked, FOG clogs pipes and triggers costly disasters—your grease trap is the first line of defense before these substances wreak havoc on your plumbing and your bottom line.

The stakes are high. According to the EPA, FOG causes nearly half of all sewer overflows nationwide¹. In Florida, violations of grease management rules (§62-6.052) result in fines ranging from $100 to $2,500 per incident². Worse, repeated violations can shut down your operation entirely.

The solution is simple. A properly maintained grease trap protects your business, your reputation, and the environment. When functioning correctly, grease traps capture 85-95% of FOG before it enters the sewer system. When Chef Carla implemented regular maintenance at her Miami restaurant, she saw unpleasant odors drop by 30% and foot traffic increase within two months.

Anatomy of a Grease Trap

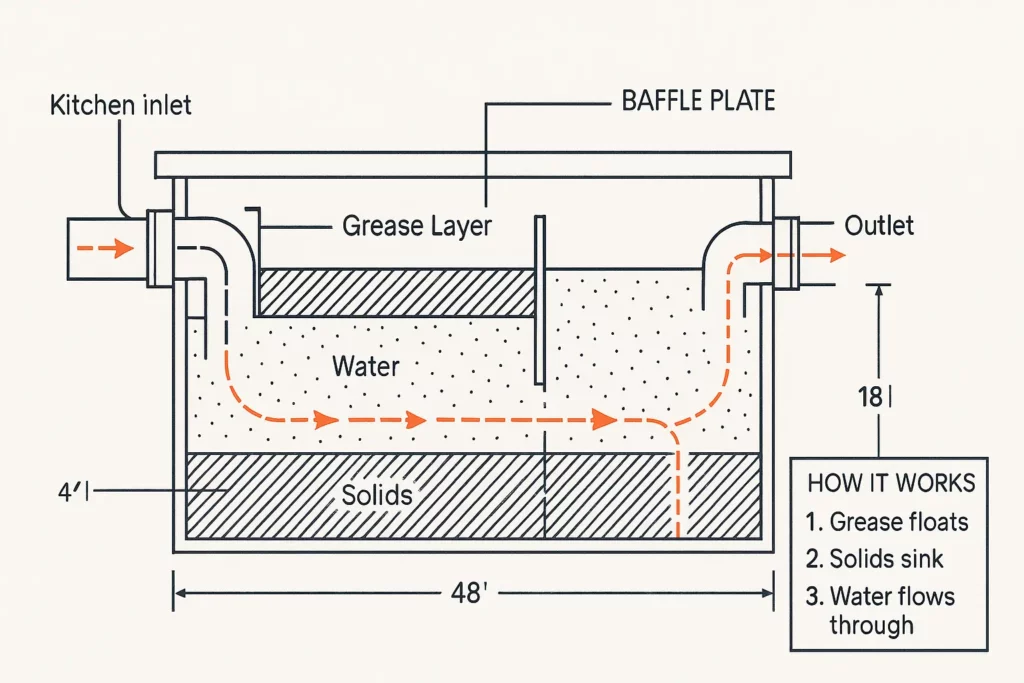

Think of your grease trap as your kitchen’s kidney—it filters out harmful substances before they poison your plumbing system. From the moment wastewater enters through the specially designed inlet, every component works together. The T-shaped fitting immediately slows the rushing water, while internal baffles create a maze that forces further deceleration.

Inside the main chamber, gravity does the heavy lifting. The outlet pipe sits strategically about 18 inches from the bottom, ensuring only the clearer middle layer of water can escape. Meanwhile, a removable strainer basket catches larger food particles before they can settle. Heavy-duty steel covers with tight gaskets seal everything shut, providing access for maintenance while preventing odors from escaping.

Larger establishments often have gravity traps with additional features—flow control devices that regulate incoming surges, and external manholes that make commercial grease trap pumping more efficient.

How Grease Traps Work

The science is elegantly simple. When wastewater enters your trap, physics takes over. The flow rate drops, allowing grease (which is lighter than water) to float to the top while solids sink to the bottom. Clean water remains in the middle layer and exits through the outlet baffle.

This natural separation process works because grease has a lower density than water—the same principle that makes oil float on your pasta water. Baffles ensure the grease stays contained while only treated water escapes to the sewer lines.

Warning Signs and Costs of Neglect

Ignoring your grease trap is like ignoring chest pains—the consequences compound quickly. Three quarters of trap failures stem from simple neglect: skipping scheduled cleanings until it’s too late. Another 15% fail when staff use hot water or harsh chemicals that push liquefied grease deeper into pipes. The remaining 10% suffer from damaged baffles that go unnoticed without regular inspections. Here’s what happens when maintenance slides:

Immediate impacts: Your first warning often comes from the dish pit; water draining slower each shift until it barely moves. Soon, that distinctive sewage smell creeps from floor drains into dining areas. Some operators notice grease actually backing up into their three-compartment sinks. By the time these symptoms appear, your trap has likely exceeded what health inspectors call the “25% threshold”; when accumulated grease and settled solids fill more than a quarter of the tank’s depth. Past this point, the trap can’t separate FOG effectively, pushing problems into your pipes and theirs.

Financial damage: Emergency plumbing calls average $500 to $1,500. Sewer backup cleanup runs $3,000-$10,000. Regular commercial grease trap pumping costs a fraction of these emergency expenses; usually $175 to $350 for under sink units or $300to $600 for larger in ground systems. Health department fines start at $500 and escalate with each violation.

Legal consequences: Florida inspectors can arrive unannounced; fail the grease check and they’ll issue a citation on the spot. Mandatory re-inspections (at your expense) follow, with potential closure orders for repeat offenders.

Hidden costs: Pest infestations thrive in grease buildup. Online reviews mention “that smell.” Your insurance premiums increase after claims. Staff turnover rises in unpleasant work environments.

Environmental impact: When FOG escapes into municipal systems, it combines with other waste to form “fatbergs”; massive sewer blockages that cost cities millions to remove. During heavy rains, these blockages force raw sewage into waterways, killing fish and contaminating drinking water sources. The EPA tracks these events, and responsible parties face both criminal charges and civil lawsuits from affected communities.

Step by Step Cleaning Playbook

Professional cleaning is recommended, but understanding the process helps you work effectively with service providers. While some operators attempt DIY cleaning, most find that waste disposal permits and proper equipment make professional service more cost-effective:

- Safety first: Workers need gloves, eye protection, and proper ventilation.

- Cool water flush: Run cool (not hot) water to solidify and float grease—hot water liquefies it, pushing problems downstream.

- Remove and measure: Document grease levels before removal (many jurisdictions require logs).

- Scrape and clean: Remove all grease and solids from walls and baffles.

- Inspect components: Check baffles, gaskets, and outlet T for damage.

- Proper disposal: Licensed haulers must transport FOG to approved facilities—illegal dumping carries criminal penalties.

Types of Grease Traps

Proper sizing depends on your kitchen’s fixture count, flow rates, and retention time requirements—Florida code mandates specific formulas that licensed engineers calculate. Here’s what’s available:

| Type | Capacity | Cleaning Interval | Best For |

|---|---|---|---|

| Automatic Grease Removal Units (AGRUs) | 50 to 100 gal | 90 to 180 days | High volume kitchens |

| Gravity traps | 1,000 to 5,000 gal | 30 to 60 days | Large facilities |

| Under-sink interceptors | 20 to 100 gal | 7 to 14 days | Individual stations |

AGRUs feature programmed skimming with higher upfront costs ($5,000-$15,000) but lower maintenance frequency. Gravity grease traps require monthly professional pumping. Under-sink units need weekly manual cleaning but cost less ($500-$2,000).

Chef Carla’s Success Story

“I used to dread Monday mornings—the weekend grease smell hit you at the door. After implementing bi-weekly cleaning and enzyme treatments, our kitchen air quality improved dramatically. We’ve had zero plumbing emergencies in 18 months, and our newest review specifically mentioned how ‘fresh and clean’ our restaurant smells. That maintenance schedule literally pays for itself.”

—Chef Carla, Biscayne Bistro, Miami

Compliance Checklist

✓ Train all staff on proper FOG disposal—no grease down drains

✓ Post cleaning schedules and logs near the trap

✓ Monitor accumulation levels regularly—health codes mandate pumping at 25% capacity

✓ Add biological treatments between cleanings

✓ Schedule professional service well before reaching critical thresholds

✓ Keep three months of maintenance records on-site

✓ Install adequate signage per local codes

Take Action Before It’s Too Late

Your grease trap works 24/7 to protect your business. Return the favor with proper maintenance. Download our grease trap maintenance schedule template or schedule a free 10 minute compliance consultation with our grease trap cleaning service specialists.

Because when it comes to grease traps, the nose knows—and by then, it’s already too late.

Sources:

- EPA. (2023). Report to Congress on Combined Sewer Overflows and Sanitary Sewer Overflows. EPA Report

- Florida Department of Environmental Protection. (2022). Grease Management Rules §62-6.052. Florida DEP