Jump to a question:

Is a grease trap the same as a grease interceptor?

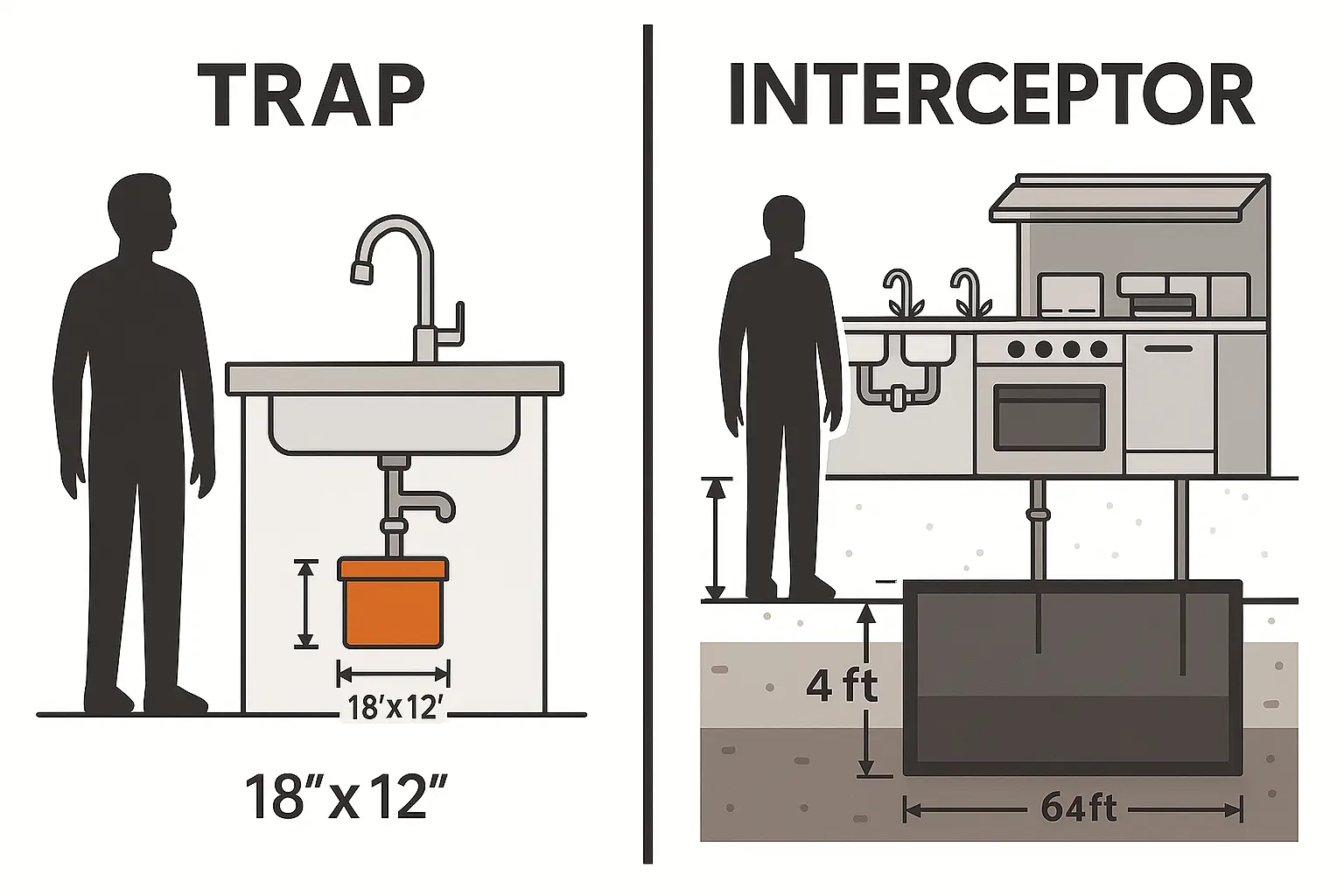

No, grease traps and grease interceptors are different devices. Grease traps are smaller units installed beneath the kitchen sink handling less than 50 gallons per minute (GPM), while grease interceptors are larger units installed underground outside buildings handling over 50 GPM.

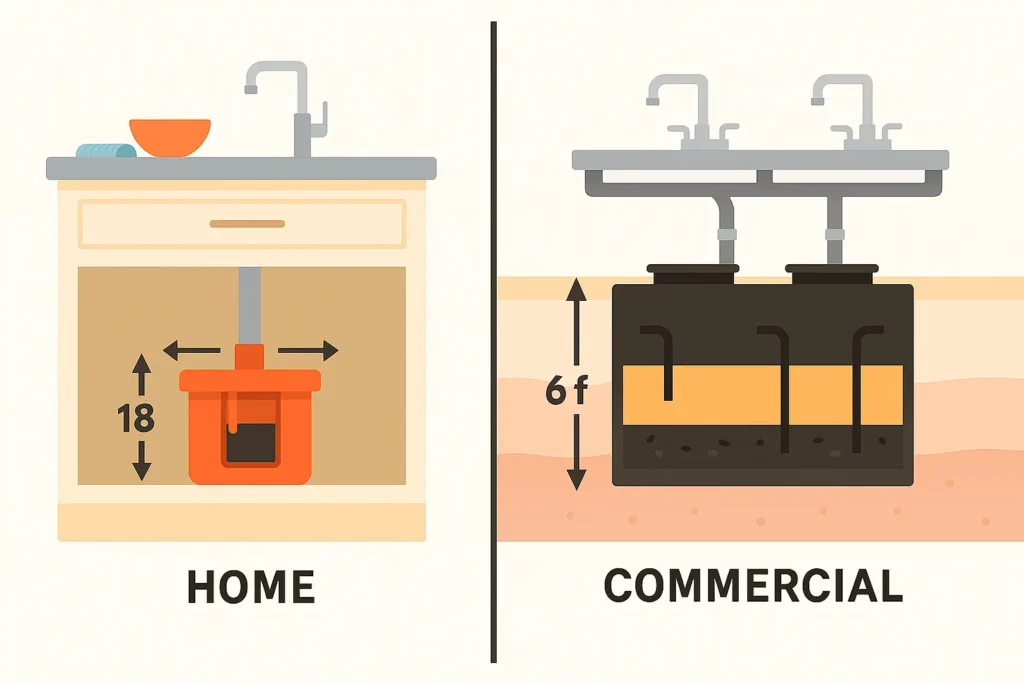

The key differences between a grease trap and interceptor lie in their size, location, and capacity. Grease traps are compact, shoebox-sized units that sit under sinks in smaller commercial kitchens like cafes and small restaurants, managing FOG (fats, oils, and grease) from daily food prep with low-pressure flow.

Grease interceptors are built for large scale establishments like schools, hospitals, and busy restaurants. These concrete or fiberglass tanks are installed underground and can handle the high-volume wastewater flows from multiple kitchen stations. While both devices prevent FOG buildup in the sewer system, interceptors have significantly larger holding capacity; starting at 500 gallons.

The technology for grease traps was invented in the 1880s and has remained nearly unchanged, proving its effectiveness. Grease interceptors work the same way: FOG hardens and floats while cleaner water flows into the sanitary sewer. Local regulations and kitchen size determine which device you need.

Summary: Grease traps and interceptors serve the same purpose but differ in size—traps handle small-volume kitchens under 50 GPM, while interceptors manage larger scale operations over 50 GPM.

What is the difference between a grease trap and a grease arrestor?

There is no difference; “grease arrestor” is simply another term for grease trap. Both refer to the same plumbing device that captures FOG from commercial kitchen wastewater before it enters the sewage system.

When wastewater flows through, the device uses gravity separation; grease floats to the top, solids sink, and cleaner water exits to the septic system or sanitary sewer. This simple yet effective design has protected plumbing systems since the 1880s.

The real distinction you need to know is between these smaller under-sink units (whether called traps or arrestors) and the larger grease interceptors used in high-volume kitchens. Focus on your flow rate and local regulations rather than terminology when selecting grease management equipment.

Summary: “Grease arrestor” and “grease trap” are interchangeable terms for the same device; focus on choosing the right size and type for your kitchen’s needs rather than the terminology.

What size grease trap or interceptor do I need for my commercial kitchen?

Size follows flow rate: choose an under-sink trap (10–500 gal) for kitchens under 50 GPM; install an outdoor interceptor (500 gal and up) if your flow rate is higher.

Calculating the right size starts with understanding your kitchen’s wastewater flows. Count your sinks, dishwashers, and floor drains, then multiply by their flow rates. A typical three-compartment sink flows 20–25 GPM, while a commercial dishwasher adds another 5–8 GPM. Small cafes with one sink might need only a 40-gallon trap, while busy restaurants require 1,000-gallon interceptors.

Under-sink traps must fit a space roughly the size of a shoebox. Grease interceptors need outdoor space for underground installation, requiring excavation and proper drainage connections. Many municipalities mandate minimum sizes based on seating capacity or meals served daily.

Undersizing saves money up front but costs more in downtime and fines. An undersized trap causes frequent foul odors, requires constant grease trap cleaning, and leads to FOG buildup that blocks pipes. Oversizing wastes money but ensures reliable operation. When in doubt, consult your local plumbing inspector who knows your area’s specific requirements for grease removal capacity or reference a grease interceptor sizing chart.

Tip: Oversizing a trap by one rating step costs about 10 percent more but can double the time between cleanings.

Summary: Choose grease trap size based on flow rate calculations; under 50 GPM needs a trap (10–500 gallons), over 50 GPM requires an interceptor (500 gallons and up).

When should I clean my grease trap vs grease interceptor?

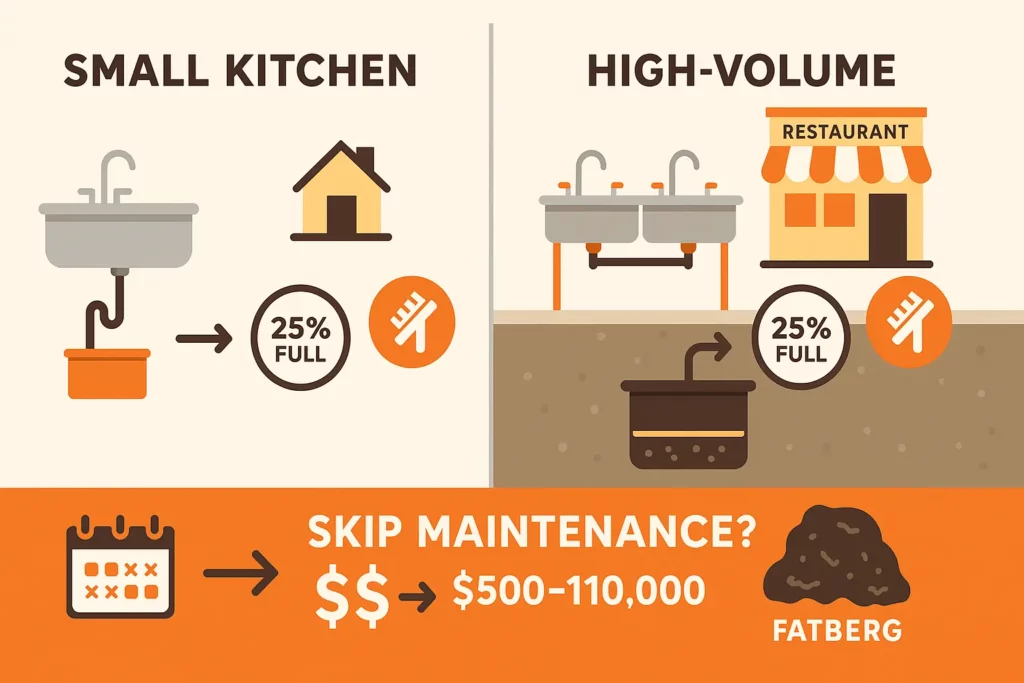

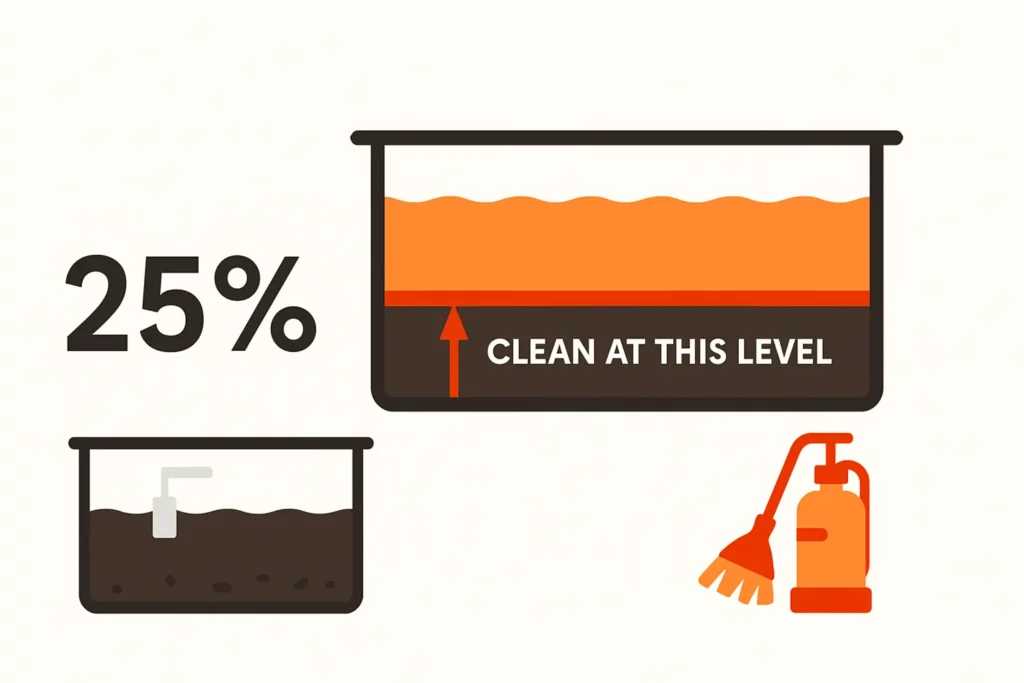

Clean grease traps when they hit 25% capacity; often once a month in busy kitchens; while larger interceptors can usually go about three months between pump-outs unless volume is very high.

Grease trap cleaning frequency depends on usage, not just time. The 25% rule is critical; once grease and solids fill one quarter of your trap’s holding capacity, efficiency drops dramatically. A busy restaurant might hit this mark weekly, while a small cafe takes a month. Check levels weekly with a dipstick to establish your pattern. Neglecting this leads to sewage system backups and expensive emergency calls.

Grease interceptors, thanks to their larger capacity, can often go three months between cleanings; though busy summer months generate more grease, so check levels more often. Regular maintenance prevents FOG from overwhelming the system and entering septic tanks or the municipal sewer.

⚠️ Warning signs demanding immediate cleaning:

- Slow drainage

- Gurgling sounds

- Foul odors from drains

- Water backing up

These indicate your grease management system is failing. Keep detailed cleaning logs; many health departments require proof of regular maintenance during inspections. Some areas mandate specific cleaning schedules regardless of capacity.

Summary: Maintain grease traps monthly or at 25% capacity, clean interceptors quarterly; but let usage patterns and warning signs guide your actual schedule for optimal grease removal.

What happens if I don’t maintain my grease management system?

Neglecting maintenance causes FOG buildup that blocks pipes, creates sewage backups, generates foul odors, and results in fines up to $25,0001. Escaped grease forms massive fatbergs in the municipal sewer system.

As grease accumulates past 25%, it hardens in the pipes like concrete, slowing sinks, backing up dishwashers, and soon filling the kitchen with rancid odors. Eventually, raw sewage backs up through floor drains, contaminating your food prep areas and forcing emergency closure.

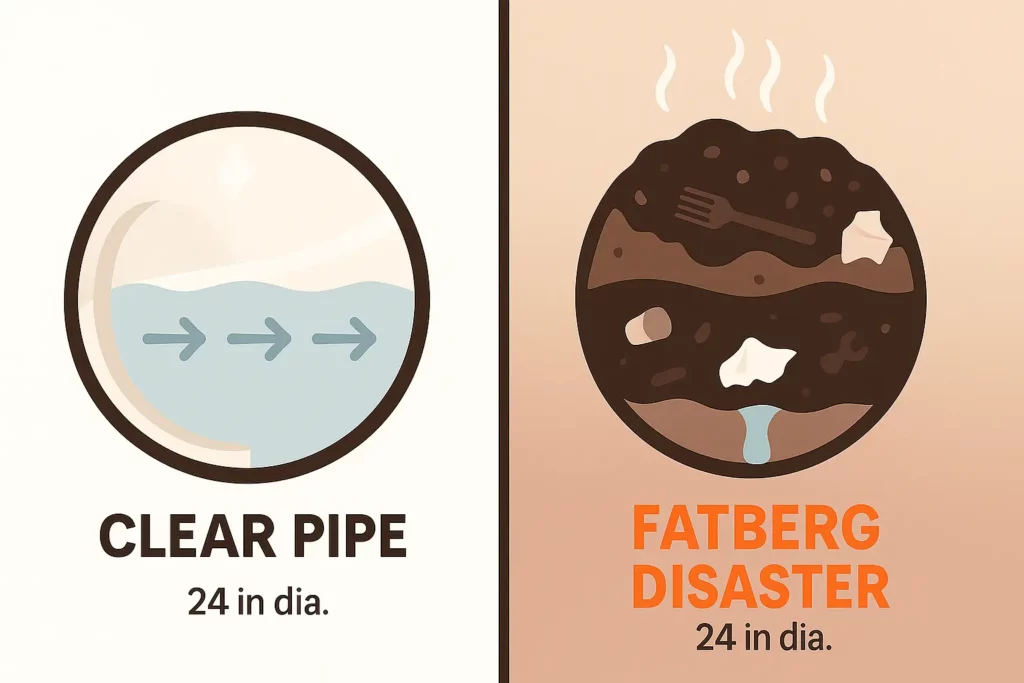

Beyond your building, escaped grease creates massive “fatbergs” in the sanitary sewer system. These blockages cause citywide overflows that damage the environment and public health. That’s why municipalities enforce strict grease management regulations with hefty fines. First violations typically start at $2,500, escalating to $25,000 for repeat offenses. Some jurisdictions pursue criminal charges for severe negligence.

The financial impact extends beyond fines. Emergency grease trap cleaning costs triple normal rates. Pipe replacement runs $5,000–$15,000. Lost business during forced closures, increased insurance premiums, and legal liability for environmental damage can bankrupt a food establishment. Regular maintenance costs pennies compared to these consequences.

Summary: Skipping grease trap maintenance leads to pipe blockages, sewage backups, business closures, and fines up to $25,000—regular cleaning is essential for any commercial kitchen.

Do I need a grease trap or grease interceptor for my food establishment?

Most commercial kitchens legally require either a grease trap or grease interceptor based on local ordinances. Small cafes typically need grease traps, while full-service restaurants require grease interceptors to handle higher grease volumes.

Most local codes require some form of grease control wherever food is prepared. Even small operations like coffee shops that only heat pastries often face mandates. The deciding factor is your menu and volume—facilities frying foods or washing greasy dishes produce enough FOG to require protection for the sewage system.

To determine which device you need, calculate your kitchen’s flow rate and grease output. Grease traps suit smaller kitchens with limited menus and fewer than 50 seats. They’re perfect for delis, small cafes, and bars serving light food. Grease interceptors become necessary for full kitchens preparing multiple meals, especially those with deep fryers, grills, and high-volume dishwashing.

Some establishments require both—a trap inside for prep sinks and an interceptor outside for the main kitchen flow. Food trucks and temporary facilities have special requirements, often needing portable grease management solutions. Contact your local health department for specific regulations, as requirements vary significantly between jurisdictions.

Summary: Yes, most food establishments need grease management devices by law—small operations use traps while larger kitchens require interceptors based on volume and local ordinances.

What is the difference between a grease trap and a petrol interceptor?

Grease traps capture FOG from kitchens to protect the sewer system, while petrol interceptors trap petroleum products from garages and car washes to prevent environmental contamination. They serve completely different industries and contamination types.

Grease traps manage fats, oils, and grease from food preparation—organic materials that solidify and clog pipes. Petrol interceptors capture gasoline, motor oil, and hydrocarbons that could poison water supplies and violate environmental regulations. You’d never use these interchangeably.

The construction differs too. Grease traps use materials suitable for hot water and food waste, requiring frequent cleaning to prevent rancid buildup. Petrol interceptors need explosion-proof designs, special ventilation, and materials resistant to petroleum chemicals. They also connect to different disposal systems—grease goes to rendering plants or approved landfills, while petroleum requires hazardous waste handling.

Grease traps sit inside kitchens or just outside, convenient for regular maintenance. Petrol interceptors sit away from buildings with specific safety clearances. If you run a food establishment, you need grease management. If you operate a garage or car wash, you need petroleum interception.

Summary: Grease traps handle kitchen FOG while petrol interceptors capture automotive fluids; they’re industry-specific devices that aren’t interchangeable despite similar separation principles.

Is an oil interceptor a trap?

An oil interceptor is a type of trap, but specifically designed for petroleum-based oils rather than kitchen grease. While both are traps that separate contaminants from water, they serve different purposes and industries.

The name sounds similar, but the substance is not. A trap is any device that captures contaminants before they hit the drain; oil interceptors do that for petroleum products, preventing motor oil, hydraulic fluid, and similar substances from contaminating the septic system or storm drains.

Don’t confuse oil interceptors with grease traps despite similar names. Kitchen grease traps handle animal fats and vegetable oils that congeal when cooled. Oil interceptors capture motor oil, hydraulic fluid, and similar petroleum products that would otherwise contaminate drains. The materials, maintenance schedules, and disposal methods differ completely.

Some facilities need both types. Large food establishments might have grease interceptors for kitchen waste and oil interceptors for delivery areas where trucks might leak. Airports, for instance, use oil interceptors on runways and grease traps in terminal restaurants. Each serves its specific purpose in protecting our sewer system and environment.

Summary: Yes, oil interceptors are traps designed for petroleum products—but they’re completely different from grease traps used in commercial kitchens for food-based FOG.

Complete grease management guide summary

Understanding grease traps vs grease interceptors is crucial for every food establishment owner. These aren’t interchangeable devices—grease traps suit kitchens under 50 GPM; interceptors serve busier operations over that mark. The technology, invented in the 1880s, remains fundamentally unchanged because it works: both devices prevent FOG from entering and clogging the sewer system through simple gravity separation.

Size and location define the key differences. Grease traps (10–500 gallons) install beneath the kitchen sink, perfect for cafes and small restaurants. Grease interceptors (500 gallons and up) require underground installation outside, built from sturdier materials like concrete to handle the demands of busy kitchens. Your choice depends on calculating actual wastewater flows—count every sink, dishwasher, and drain, then multiply by their flow rates to determine your needs.

Maintenance schedules vary significantly. Clean grease traps monthly or when they reach 25% capacity to prevent FOG buildup and foul odors. Grease interceptors need cleaning every three months due to their larger holding capacity. Neglecting regular maintenance causes catastrophic problems: pipe blockages, sewage backups, health code violations, and fines up to $25,000. The cost of emergency repairs far exceeds routine cleaning expenses.

Local ordinances mandate grease management for most food establishments, making this an environmentally friendly necessity, not an option. Whatever they’re called, these devices protect both your plumbing and the municipal sewage system. Don’t confuse them with petrol or oil interceptors used in automotive settings—kitchen grease management requires specific equipment designed for fats, oils, and grease from food preparation. Invest in the right system for your operation’s size and maintain it properly to ensure smooth, compliant operations every day.

EPA Clean Water Act enforcement data (2024)2

Find professional grease trap services near you →