Table of Contents

The Awakening at Sunrise Bakery Systems

The conveyor belts at Sunrise Bakery Systems in Tampa never stop. Every hour, 10,000 donuts emerge from massive fryers, golden and perfect. For twenty-three years, plant manager Carlos Mendez viewed the 500 gallons of used cooking oil generated daily as nothing more than an expensive disposal headache. The oil accumulated in enormous storage tanks behind the facility, a dark reminder of operational costs that seemed as inevitable as the sunrise itself.

Carlos found something that would fundamentally change how industrial food producers across Florida view their operations: that “waste” oil was worth more than the flour they were buying.

This revelation began a journey that would transform not just Sunrise Bakery’s bottom line, but their entire approach to sustainable manufacturing. The question “Can you get paid for used cooking oil in Florida?” suddenly shifted from idle curiosity to urgent business strategy.

Find Your Waste Oil Profit

Get a 48-hour audit and see what your used oil is really worth.

The Industrial Scale

Carlos wasn’t alone in his ignorance. Across Florida, bread factories, empanada manufacturers, snack food plants, and industrial kitchens were hemorrhaging money through their used cooking oil disposal. These weren’t restaurants dealing with a few dozen gallons monthly; these were industrial facilities producing thousands of gallons of used oil, treating it as hazardous waste requiring expensive disposal.

The truth emerged through a chance conversation at an industry conference. A competitor mentioned they were actually getting paid for their used cooking oil; substantial amounts that were impacting their quarterly earnings. The oil wasn’t waste at all, but rather a valuable commodity in the renewable energy market.

Carlos learned why professional cooking oil collection services were desperate for high-volume, consistent sources of quality oil. Industrial producers offered exactly what the biodiesel and renewable diesel industries needed: massive quantities of relatively clean oil from controlled processes. Unlike restaurants with varied cooking methods and contamination risks, factories maintained consistent temperatures, filtration systems, and oil quality standards that made their waste oil a particularly valuable controlled processes; making Sunrise one of the bulk fryer oil buyers Florida collectors fight to secure. .

The Science of Scale

The journey from industrial fryer to renewable fuel follows a fascinating path that Carlos had never imagined. When cooking oil services collect from industrial facilities, they’re not dealing with the 55-gallon drums common at restaurants. Instead, massive tanker trucks connect directly to storage tanks holding thousands of gallons, pumping oil through specialized equipment designed for industrial-scale transfer.

At processing facilities across Florida, the waste vegetable oil (WVO) Florida plants generate is collected in bulk. When oil is aggregated at this scale, conversion efficiency rises dramatically. Waste oil from bread factories becomes biodiesel that powers delivery trucks. Oil from snack-food plants is refined into sustainable aviation fuel, helping airlines hit carbon-reduction goals. Even the glycerin by-product finds a second life in resins and cosmetics, creating the circular economy Carlos had never imagined.

Industrial producers typically maintain higher oil quality than foodservice businesses because of their controlled processes. Automated fryers maintain precise temperatures. Industrial filtration systems remove particles continuously. Climate controlled environments prevent moisture contamination. This meant industrial oil often commanded premium prices—sometimes reaching $0.75 to $1.00 per gallon for the cleanest batches.

The Compliance Catalyst

Waste-oil disposal (industrial fryer-oil disposal): $73 000

But Carlos’s education was just beginning. The Florida Department of Environmental Protection had been tightening regulations around industrial waste disposal, and used cooking oil sat squarely in their crosshairs. The days of simply paying a waste management company to “handle it” were ending.

State inspectors arrived unannounced, examining Sunrise Bakery’s waste disposal practices. While they passed, the inspector mentioned new regulations coming into effect: stricter documentation requirements, enhanced environmental protection measures, and substantially higher fines for violations. Industrial facilities pouring oil down drains or allowing it near storm drains faced penalties starting at $10,000—per incident.

The inspector shared something unexpected: facilities partnering with certified cooking oil recycling services automatically met all regulatory requirements. These services provided complete documentation for regulatory compliance, handled all transportation permits, and ensured proper disposal chains that satisfied even the strictest audits.

Until that moment, Carlos had viewed environmental compliance as a cost center. Now he saw it as a potential profit center that simultaneously eliminated compliance headaches.

The Implementation Journey

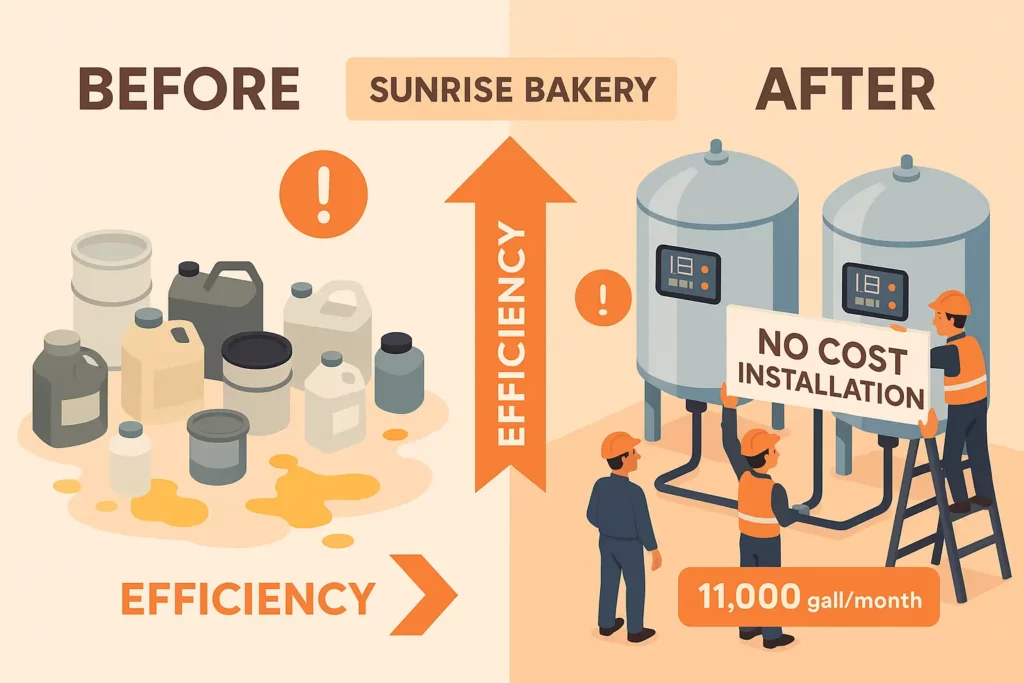

Carlos’s transformation of Sunrise Bakery’s oil management began with a comprehensive assessment. Working with industrial cooking oil collection specialists, they discovered their facility was producing 11,000 gallons monthly—enough to power a small fleet of biodiesel vehicles.

And then came the infrastructure evaluation. Unlike restaurants using simple containers, industrial facilities required sophisticated systems:

Storage Solutions: Industrial-grade storage tanks with 5,000-gallon capacities replaced their hodgepodge of smaller containers. These tanks included:

- Automated level monitoring to prevent spills

- Temperature controls maintaining oil quality

- Sealed systems preventing contamination

- Secondary containment meeting environmental regulations

Transfer Systems: Professional services installed direct-connect pumping systems, eliminating manual handling and preventing spills that had previously created safety hazards and environmental risks.

Quality Management: New filtration and testing protocols ensured oil maintained maximum value throughout storage.

The real surprise: most of this equipment came at no cost as part of the service agreement. The cooking oil collection company viewed it as an investment in securing a reliable, high-volume supplier.

The Financial Transformation

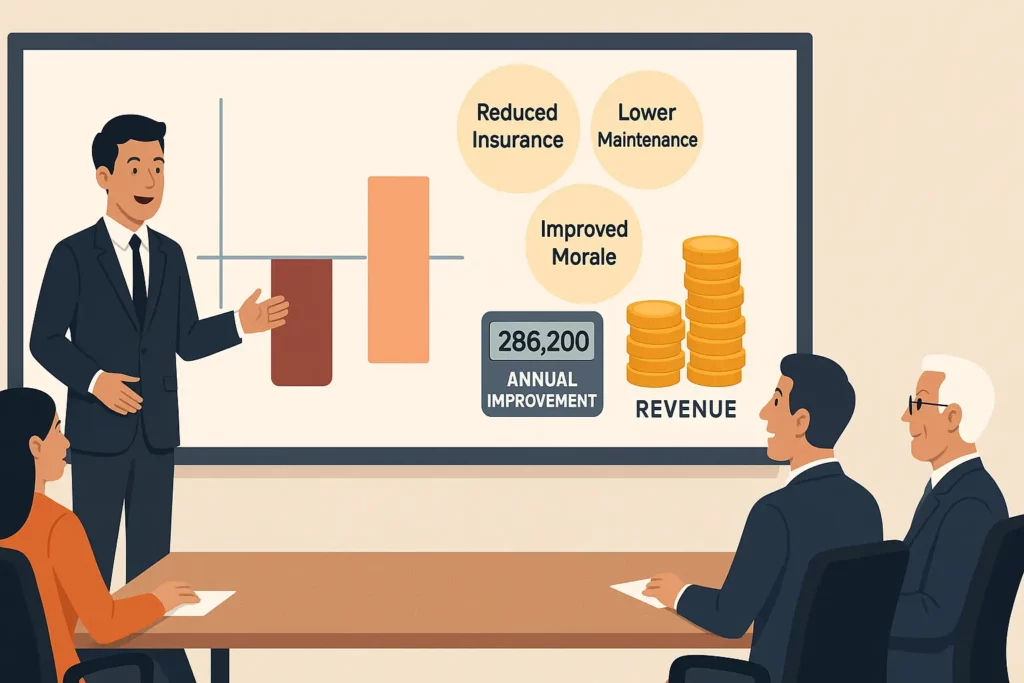

The numbers Carlos presented to corporate leadership seemed almost too good to be true. But the math was undeniable:

Previous Annual Costs:

- Waste oil disposal: $73,000

- Environmental compliance: $12,000

- Spill cleanup/maintenance: $8,000

- Total: $93,000 in expenses

New Annual Revenue Model:

- Oil sales (11,000 gallons/month @ $0.85): $112,200

- Eliminated disposal costs: $73,000

- Reduced compliance costs: $8,000

- Total: $193,200 in value

The swing from $93,000 in costs to $193,200 in value—a $286,200 annual improvement—captured corporate attention immediately.

And then came additional benefits Carlos hadn’t initially calculated. Insurance premiums decreased due to improved safety protocols. Maintenance costs plummeted as proper equipment prevented the clogs and spills that had plagued their drainage systems. Employee morale improved as workers no longer dealt with dangerous, messy oil disposal tasks.

2025 UCO Price Chart

Check the latest per-gallon rebate rates updated weekly across Florida. Compare your potential payout against live market prices before you schedule a pickup.

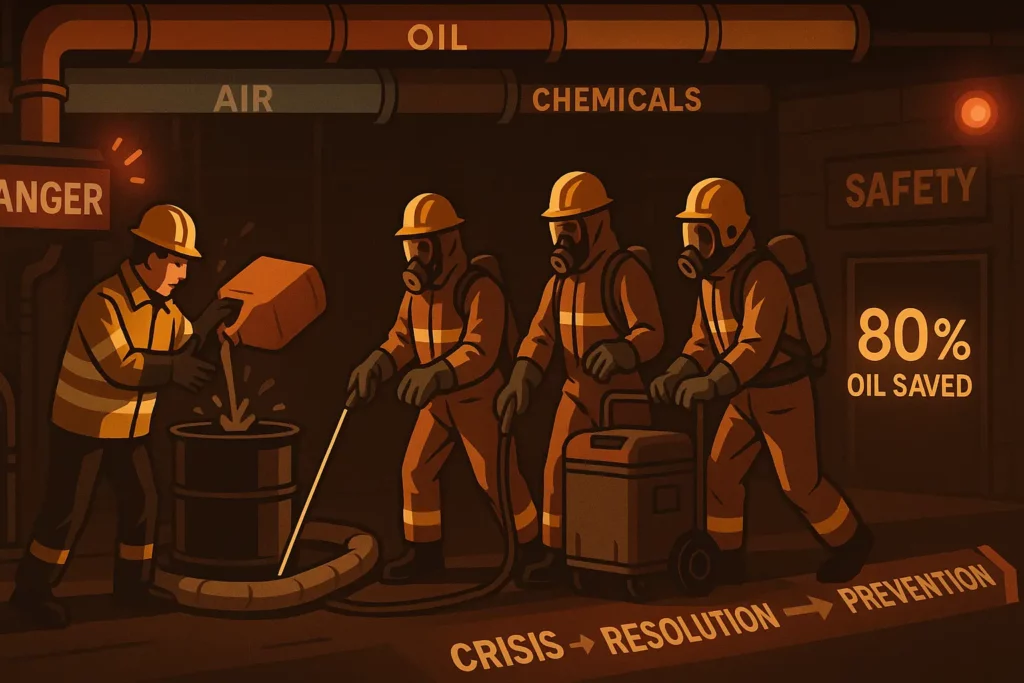

The Contamination Crisis and Resolution

Six months into their new program, disaster nearly struck. A night shift supervisor, unaware of the new protocols, directed cleaning crews to dump fryer cleaning solution into the oil storage tanks. The contamination—harsh chemicals mixed with water—threatened to ruin 3,000 gallons of oil.

Their cooking oil service partner’s value became crystal clear. Instead of rejection and disposal costs, their provider’s emergency response team arrived with mobile testing equipment. They isolated the contaminated section, saving 80% of the oil through specialized treatment processes.

The service provider conducted comprehensive training for all shifts, explaining how water, food particles, cleaning agents, and especially motor oil contamination could destroy oil value. They implemented visual management systems—color-coded pipes, multilingual warning signs, and foolproof connection systems preventing future accidents.

Until this crisis, some staff had remained skeptical about the importance of oil quality. After seeing potential losses prevented through proper handling, everyone understood their role in maximizing this new revenue stream.

The Network Effect

Carlos’s success at Sunrise Bakery didn’t go unnoticed. Other industrial food producers began reaching out—tortilla factories, industrial cafeterias, prepared meal facilities, even cosmetics manufacturers using vegetable oils. They all faced similar challenges and opportunities.

A remarkable collaboration emerged. Several facilities in the same industrial park coordinated their oil collection schedules. This concentration of high-volume producers allowed their cooking oil service to offer even better rates—economies of scale benefiting everyone. The facilities shared best practices, creating an informal network of industrial oil producers maximizing their returns.

And then environmental groups took notice. The collective impact of these facilities diverting thousands of gallons from waste streams into renewable fuel production earned recognition from the Florida Department of Environmental Protection. This positive publicity attracted environmentally conscious clients, creating unexpected business development opportunities.

The Technology Revolution

As industrial cooking oil recycling matured, technology transformed operations beyond Carlos’s wildest expectations. Modern tracking systems provided real-time visibility into every aspect of their oil management:

Automated Monitoring: Sensors in storage tanks tracked oil levels, quality metrics, and potential contamination, alerting staff before problems developed.

Predictive Analytics: Software analyzed production patterns, predicting optimal collection schedules and preventing overflow incidents.

Digital Documentation: Blockchain-based tracking created unalterable compliance records, simplifying audits while ensuring complete transparency.

Quality Optimization: Continuous monitoring identified the perfect moment to change fryer oil—maximizing both food quality and oil value.

The integration with their existing manufacturing systems. Oil management became part of their overall efficiency metrics, with dashboards showing real-time revenue generation from what was once a waste stream.

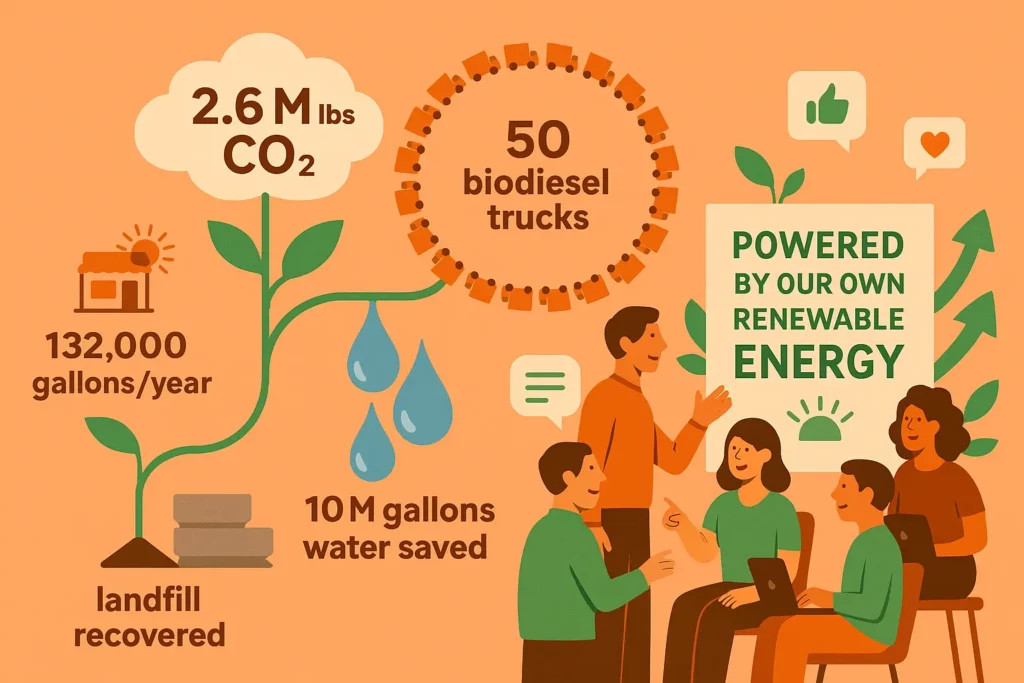

The Sustainability Dividend

The environmental impact of industrial scale oil recycling dwarfed what Carlos had initially imagined. Sunrise Bakery’s 132,000 gallons annually translated to:

- 2.6 million pounds of CO2 prevented

- Enough biodiesel to power 50 delivery trucks year-round

- Water pollution prevention equivalent to treating 10 million gallons

- Landfill diversion saving 500 cubic yards of space annually

Marketing seized the opportunity. “Powered by Renewable Energy from Our Own Operations” became a powerful message resonating with corporate clients. Major retailers specifically sought suppliers demonstrating circular economy principles. The cooking oil recycling program opened doors to contracts Carlos never thought possible.

Employees became ambassadors. Proud of their company’s environmental leadership, they shared the story on social media, attracting both customers and quality job candidates who valued working for a sustainable company.

The Regulatory Evolution

As more industrial facilities embraced oil recycling, Florida regulations evolved to encourage the practice. The state recognized that industrial producers represented massive potential for renewable fuel production and environmental protection.

The incentive programs for tax credits for facilities diverting substantial waste from landfills. Expedited permitting for companies demonstrating environmental excellence. Even grants for equipment upgrades improving oil quality and collection efficiency.

But regulations also tightened for non-participants. Facilities still treating oil as waste faced escalating disposal costs and stricter monitoring. Environmental compliance audits increased in frequency and severity. The message was clear: evolve or pay the price.

Until these regulatory changes, some facilities had postponed transitioning to recycling programs. Now, the combination of financial incentives and compliance requirements made the decision inevitable.

Lessons Learned: The Industrial Advantage

Three years after beginning their cooking oil recycling journey, Carlos reflected on the transformation. What started as a simple question—”Is used cooking oil worth money?”—had revolutionized their operations.

The key lessons for industrial producers were clear:

Scale Matters: Industrial volumes command premium prices and justify infrastructure investments impossible for smaller producers.

Quality Control: Controlled manufacturing environments produce consistently higher-quality oil than foodservice operations.

Integration Opportunities: Oil recycling integrates naturally with other sustainability initiatives, multiplying benefits.

Network Effects: Collaborating with nearby facilities creates mutual advantages through economies of scale.

Technology ROI: Advanced monitoring and management systems pay for themselves through prevented losses and optimized collection timing.

The ultimate realization: what they’d viewed as an unavoidable cost of production had become a competitive advantage. Facilities still paying for disposal couldn’t match the economics of those earning from their oil.

The Future of Industrial Oil Recycling

Looking ahead, Carlos sees even greater opportunities. Emerging technologies promise to extract more value from used cooking oil. New renewable fuel standards increase demand. Industrial facilities investing in oil quality management position themselves for premium markets.

Young engineers joining Sunrise Bakery arrive expecting sustainable practices. They bring fresh ideas for optimizing oil use, minimizing waste, and maximizing value. What was once Carlos’s special project has become embedded in their operational DNA.

Until that first conversation about getting paid for used cooking oil, Carlos had accepted waste as inevitable. Now he views every drop of oil as potential revenue, every improvement as competitive advantage, every gallon recycled as environmental leadership.

Your Industrial Facility’s Path Forward

The question isn’t whether industrial food producers can get paid for used cooking oil in Florida; it’s how much money you’re currently leaving on the table. With industrial facilities generating anywhere from 5,000 to 50,000 gallons monthly, the financial impact of not recycling is staggering.

Professional cooking oil collection services specializing in industrial accounts offer:

- Turnkey infrastructure installation

- Comprehensive compliance management

- Premium pricing for high-volume producers

- 24/7 monitoring and emergency response

- Integration with existing operations

The transformation from cost center to profit center typically takes less than 90 days. Most facilities see positive cash flow from their first full month of operation.

Summary and Closing

Every day your facility continues treating cooking oil as waste represents lost revenue and unnecessary environmental impact. The industrial producers already participating in oil recycling programs gain competitive advantages that compound over time.

The facts are undeniable:

- Used cooking oil from industrial facilities commands premium prices

- Professional services eliminate disposal costs while generating revenue

- Regulatory compliance becomes automatic with proper partnerships

- Environmental leadership attracts customers and employees

- Technology makes implementation and management effortless

Carlos Mendez transformed Sunrise Bakery Systems from spending $93,000 annually on oil disposal to generating over $190,000 in value. Similar opportunities exist at every industrial facility using cooking oil in Florida.

The time for viewing used cooking oil as waste has ended. The era of turning that oil into competitive advantage has begun. Your facility’s transformation starts with a single phone call to a professional industrial cooking oil service.

Don’t let another gallon; or another dollar; slip away. The future of sustainable, profitable manufacturing includes monetizing every resource, and your used cooking oil represents the lowest-hanging fruit on the tree of opportunity.