Table of Contents

Why Size Matters in Florida

Grease interceptors are silent workhorses, but if they’re undersized your kitchen will back up faster than an afternoon storm on I 95. In Florida, inspectors judge capacity first because the state’s warm climate accelerates FOG (fats, oils, grease) solidification. The right volume prevents overflow, keeps pH levels stable, and cuts pump out frequency, saving thousands in haul off fees each year. More importantly, compliance with Chapter 10 of the Florida Building Code and county FOG ordinances is mandatory for your health permit to stay active. Choosing the correct size upfront means fewer emergency calls and less lost revenue when tourist season peaks.

The Regulatory Sizing Framework

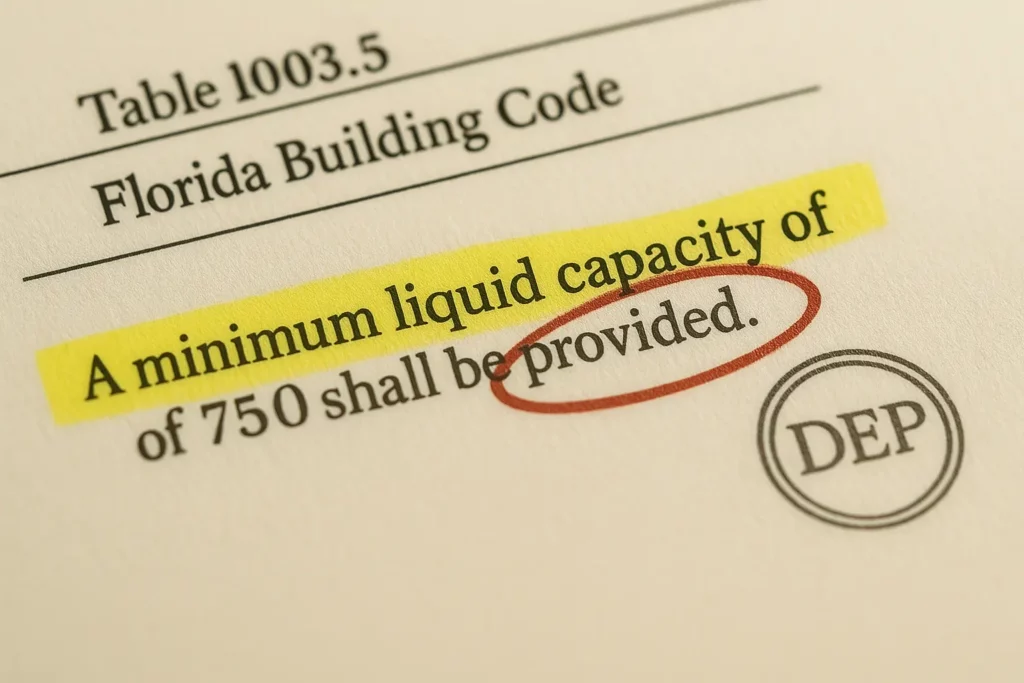

Florida uses a dual system: hydromechanical grease traps (HGTs) inside the building and gravity grease interceptors (GGIs) outside. FAC 64E 6 sets a minimum 750 gallon volume for any gravity unit and caps a single chamber at 1,250 gallons. Above that, tanks must be placed in series. Hydromechanical units are measured by flow rate (gallons per minute, GPM) and grease retention (pounds). Counties layer on stricter rules; Orange and Miami Dade county require engineering sheets showing fixture counts and daily flow before issuing a permit. When DOH or DEP reviews your plans, they will check these figures against Table 1003.5 of the Florida Building Code, so your sizing worksheet must match field reality.

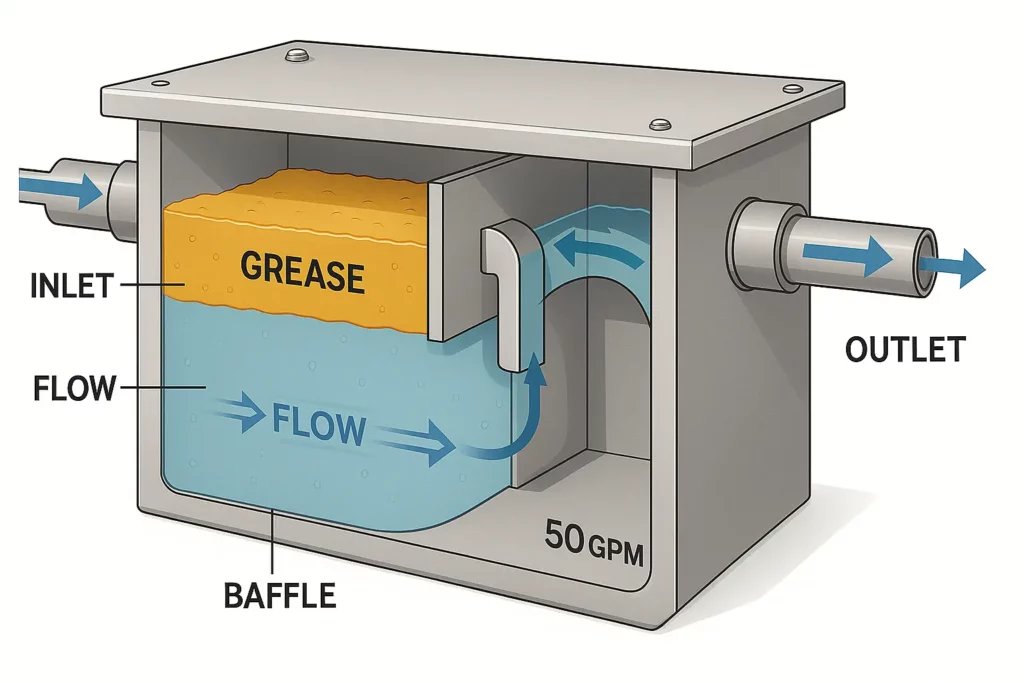

Compact Hydromechanical Interceptors (Under Sink)

Hydromechanical models sit close to the source, often under the three compartment sink or wok station. They range from 20 GPM/40 lb units for coffee shops to 100 GPM/200 lb boxes for high volume QSRs. Because the flow is turbulent, they separate FOG within minutes, but they fill quickly; most operators schedule weekly pump outs. Look for third party certification (PDI G101, ASME A112.14.3) and a quick clean baffle design to cut labor time. Stainless steel resists the coastal humidity that corrodes cheaper painted steel. If you install a dishwasher downstream, factor its discharge temperature; above 140 °F can remobilize captured grease and void capacity ratings.

| Hydromechanical Size | Typical Application |

|---|---|

| 20 to 35 GPM / 40 to 70 lb | Coffee bars, bakeries |

| 50 to 75 GPM / 100 to 150 lb | Full service restaurants |

| 100 GPM / 200 lb | Resort banquet kitchens |

Standard Gravity Interceptors (750 to 1,500 Gallons)

The workhorse for stand alone restaurants is the buried gravity tank. Florida code fixes the low end at 750 gallons; anything smaller fails plan review, while most building officials lean toward 1,000 or 1,250 gallons to handle rush hour spikes. Fiberglass shells are popular in coastal zones because they resist saltwater intrusion; precast concrete dominates inland for price and traffic load. Installing a sampling tee downstream is a Florida best practice: it gives inspectors a quick window into effluent quality and lets operators self monitor before fines hit. Schedule maintenance every 90 days or when the grease layer reaches 25% of liquid depth, whichever comes first.

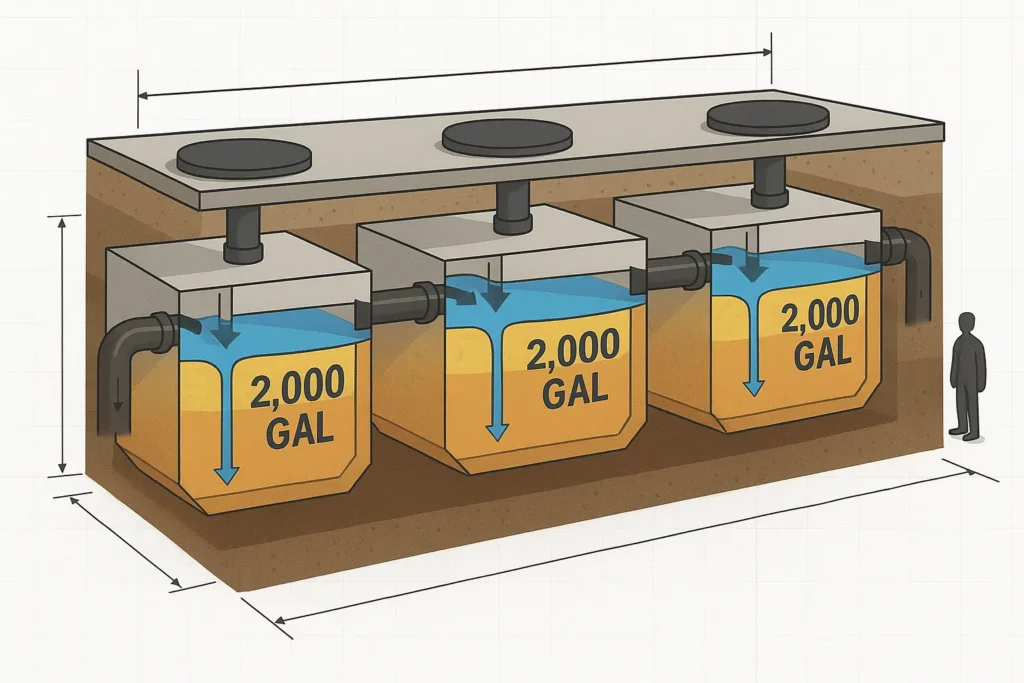

High Capacity Modular Systems (2,000 to 5,000 Gallons)

Food courts, stadiums, cruise terminals, and central commissaries can discharge more grease in one lunch rush than a diner emits all week. For them, engineers specify twin or triple tanks in series, often 2 × 2,000 gallons or 3 × 1,600 gallons, to satisfy the flow equations in FBC Table 1003.5 without overshooting the 1,250 gallon single chamber cap. HDPE vaults are gaining traction because sections snap together like PVC, shortening install time in high groundwater areas. Many operators add an inline flow meter and cellular level sensor; data proves compliance and optimizes pump out contracts. Plan a traffic rated lid if delivery trucks cross the pad.

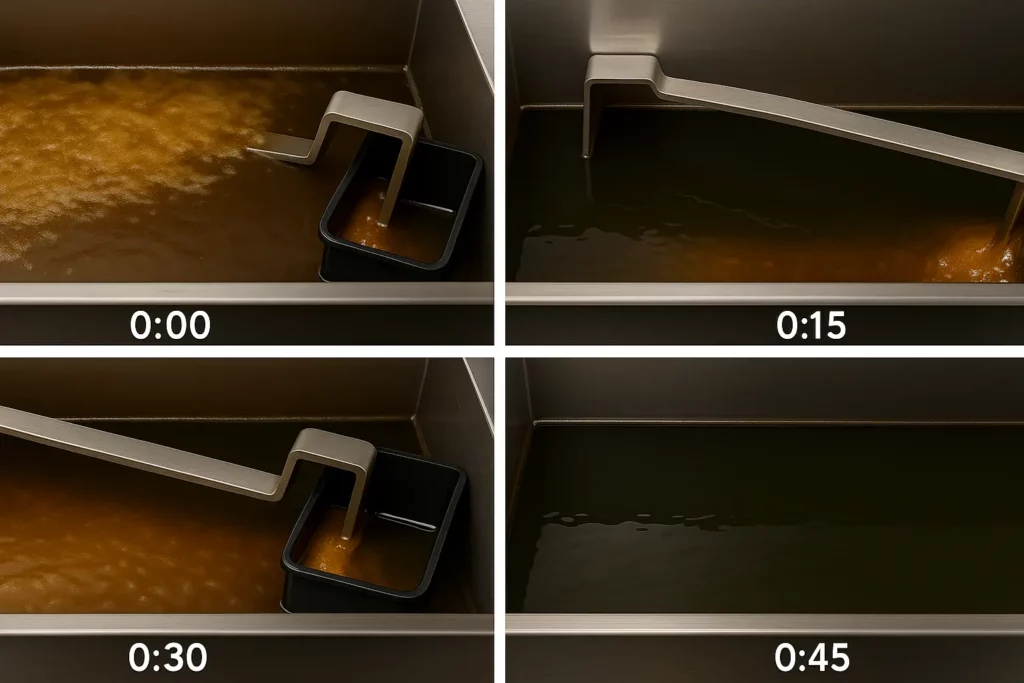

Automatic Grease Recovery Devices (AGRDs)

AGRDs skim grease into a tote on a timer, combining separation and storage in one small footprint. Florida allows them when floor space is tight, but only if the recovery rate matches fixture flow. Models run 8 to 75 GPM and typically hold 15 to 50 lb of grease before the tote needs emptying. A programmable heater keeps fats liquid, critical in air conditioned prep rooms. Verify UL listing to avoid electrical red tags, and connect the outlet to a CCTV accessible cleanout; DEP inspectors increasingly request video proof that no bypass occurs. Because AGRDs discharge virtually grease free water, they can extend the service interval of a downstream gravity interceptor.

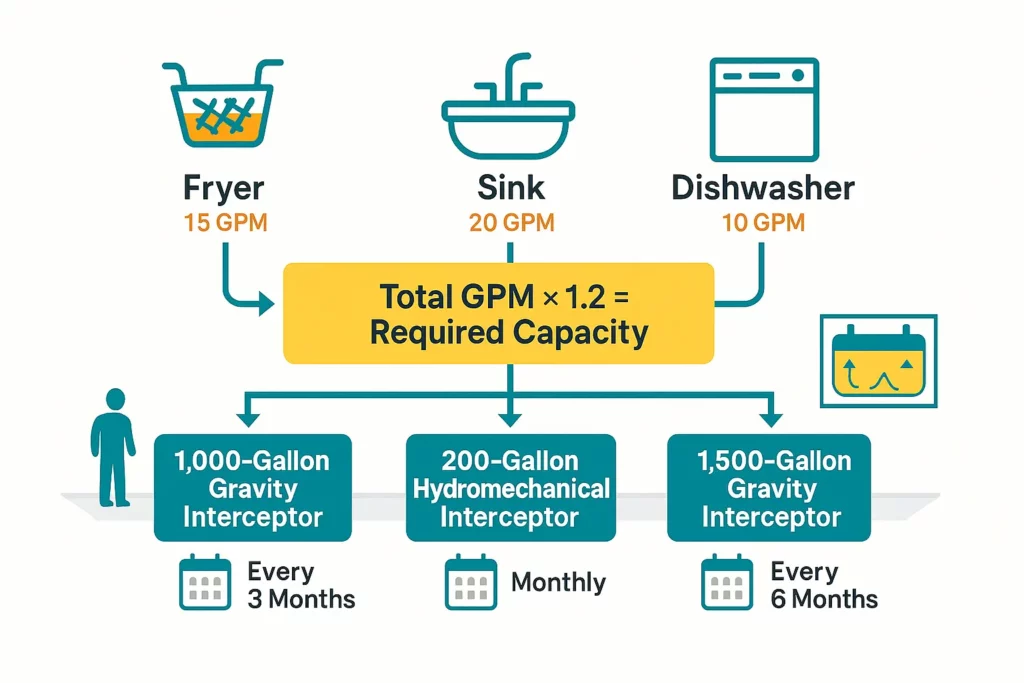

How to Choose the Right Capacity

Start by listing every FOG producing fixture: fryers, woks, pot sinks, and multiplying by their drain diameters to find total GPM. Cross check with Table 1003.5 to select an interceptor whose rated flow exceeds peak by at least 20%. If gravity units are required, round up to the next 250 gallon increment; Florida inspectors rarely approve “just enough” sizing. For AGRDs, match the unit’s skimming rate to your fryer’s oil turnover. Finally, model pump out costs: sometimes a 1,250 gallon tank with quarterly service is cheaper long term than an 800 gallon tank pumped monthly. Remember, right sizing is both an engineering calculation and a cash flow decision; get it wrong, and you’ll pay in downtime and fines.

Need help sizing or installing? Our certified interceptor specialists design, permit, and service units across Florida’s 67 counties, so your kitchen stays open and code compliant year round.