Table of Contents

Summary

Cold weather turns used cooking oil (UCO) into a slow moving, waxy solid that clogs pipes, stalls vacuum pumps and violates FOG rules. This guide explains why oil thickens, the operational failures it triggers, and, most importantly, the proven equipment upgrades, heat trace techniques, logistics tweaks and compliance steps that keep winter collections flowing. Follow these expert level practices and your fryers, haulers and biodiesel partners will glide through sub freezing months without costly call outs or fines.

Understanding How Cold Affects Used Cooking Oil

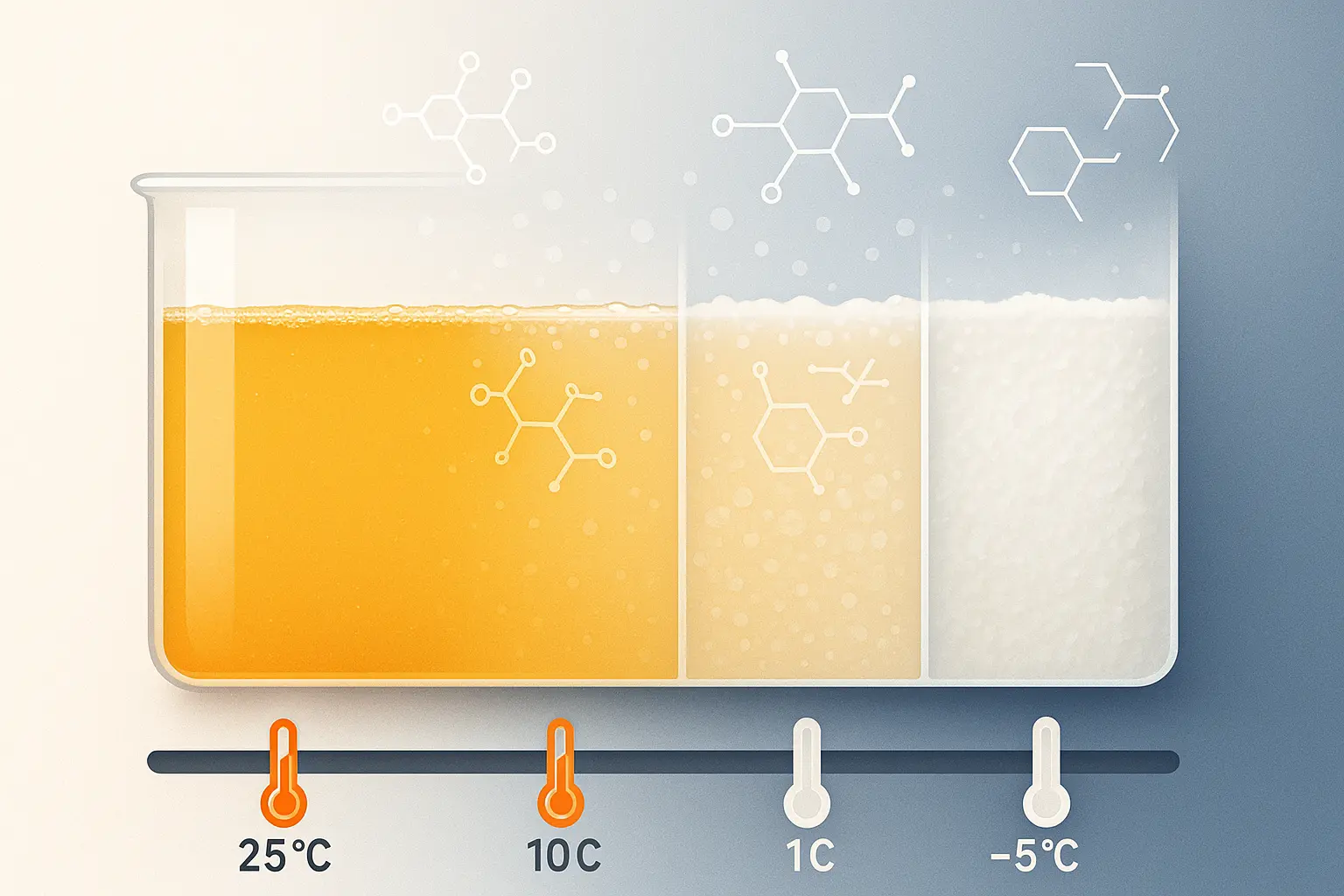

Used cooking oil begins to cloud just above the freezing point of water; soybean based oil hazes at about 1 °C (34 °F) and animal fats can solidify above 40 °C (104 °F), sharply raising viscosity, according to Farm Energy Extension and laboratory viscosity studies. Thicker oil moves up suction hoses more slowly, increases pump amperage and can stall diaphragm pumps altogether. Cooling also accelerates free fatty acid crystallisation, creating waxy platelets that block strainers. The result is a system that behaves as though it were half full of concrete.

| Oil Type | Cloud Point | Pour Point* | Practical Risk Level |

|---|---|---|---|

| Soybean | 1 °C / 34 °F | -3 °C / 26 °F | Hoses slow; filters clog |

| Canola | -1 °C / 30 °F | -6 °C / 21 °F | Moderate |

| Tallow rich blend | > 40 °C / 104 °F | > 35 °C / 95 °F | High: solid at room temp |

Winter Collection Challenges on the Ground

Restaurant alleys turn into “no pump zones” once oil reaches its pour point; trucks idle longer, spill risks rise and staff face slip hazards from congealed grease, according to industry experts. Frozen lids and locking mechanisms delay pick ups, while inside the kitchen, grease traps harden faster, pushing FOG back into drains and risking municipal violations. Collection teams must also manage battery drain on lift gates and PTO units that work harder against thicker fluids, increasing diesel consumption.

Engineering & Equipment Solutions

Heated outdoor bulk containers with built in thermostats keep oil above 15 °C (59 °F), preventing wax formation, according to industry research. Where grid power is unavailable, double walled, foam insulated totes with removable thermal blankets offer passive protection and can maintain > 10 °C (50 °F) for 24 hours in -10 °C ambient, per equipment manufacturer data. Hose lines on the truck side should be jacketed with self regulating heat trace cable to keep the fluid path above 20 °C; industrial freeze protection providers document 5 to 10 W/ft loads as sufficient for UCO viscosities.

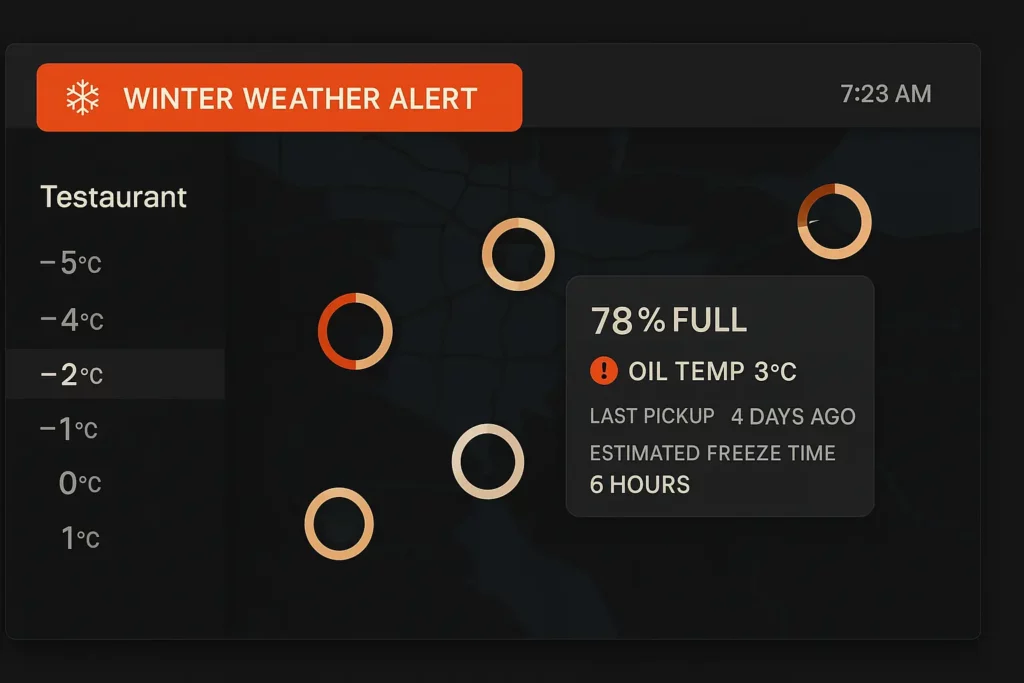

Optimizing Pickup Logistics and Monitoring

Schedule winter collections for mid day, when ambient temperatures are highest; industry reports show viscosity drops of up to 20% between 8 a.m. and 1 p.m. on 0 °C days. Equip tanks with ultrasonic level sensors that transmit via cellular to trigger pick ups only when volumes justify a warm truck roll; remote fill systems cut emergency visits by 30%. Drivers should perform a two minute “hose warm up” by recirculating oil through the truck’s onboard heater loop before suction begins to avoid pump cavitation.

Safety, Compliance & FOG Regulations

FOG ordinances do not relax in winter. Hardened grease in external traps can breach 25% capacity rules within days, leading to fines, according to industry compliance experts. Inside, colder dishwater sets fats faster, so staff must flush lines with 43 °C (110 °F) water after each rush, environmental consultants note. Outdoor spills solidify quickly and become slip and fall liabilities; carry biodegradable absorbent and a propane torch to re liquefy spots for proper capture. Document clean up in your FOG log to satisfy inspectors.

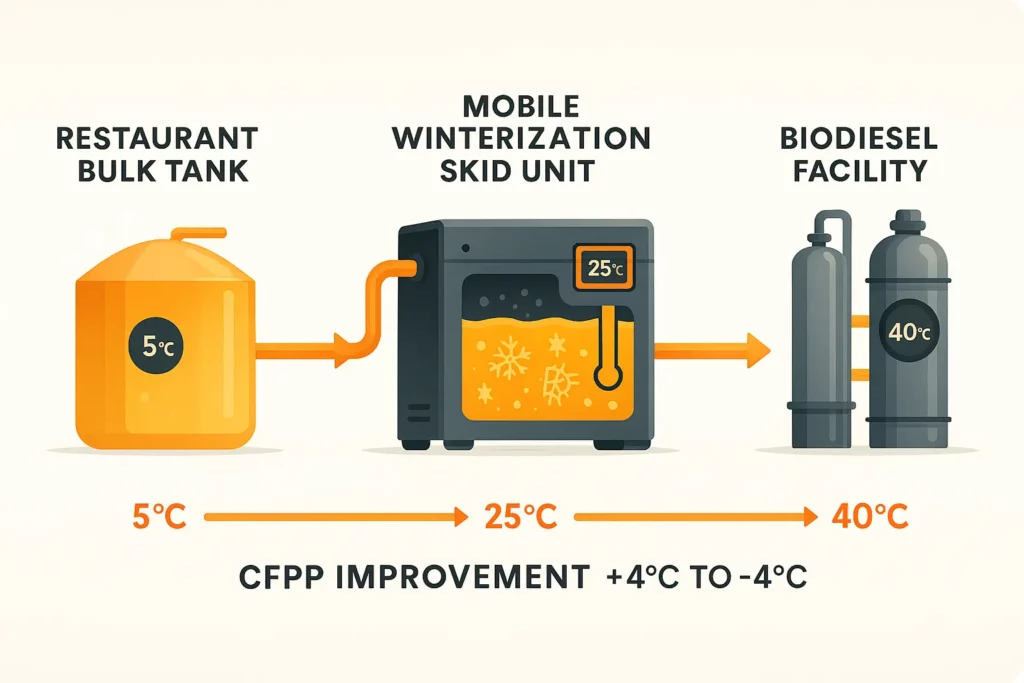

Preparing Oil for Biodiesel: Winterization Essentials

Biodiesel producers reject loads whose cold filter plugging point (CFPP) exceeds 0 °C. Waste oil biodiesel typically shows a CFPP of +4 °C, but winterization, filtering, chilling and decanting saturates, lowers CFPP by 6 to 8 °C, according to recent studies. Haulers that deliver pre screened, water free oil can capture a 3 to 5 ¢/lb. premium even in January. Keep loads covered and de watered: each 1% water raises pour point by roughly 0.5 °C.

Expert Routine for Sub Freezing Mornings

- Power up heat trace cables one hour before departure (self regulating models draw minimal idle power).

- Recirculate truck tank to 25 °C using onboard heat exchanger.

- Verify lid gaskets remain flexible; replace if rigid to stop vacuum leaks, industry experts advise.

- Use insulated drip trays under quick connects to catch cooling drips.

- Log viscosity reading with handheld viscometer; anything above 200 cP at 20 °C triggers a heated flush.

Cost Benefit Snapshot

| Mitigation | Up Front Cost (avg.) | Winter Failure Cost Avoided | Payback Period |

|---|---|---|---|

| Heat traced 50 ft hose | $780 | $1,500 pump replacement | 6 months |

| Heated outdoor bulk tank | $2,900 | $4,000 flood & clean up fine | 1 winter |

| Remote level sensor | $350 | $800 emergency pick up | 4 months |

Conclusion: Protect Profit, Protect Pipes

Cold weather is inevitable; frozen grease is not. By marrying insulated storage, heat trace technology and data driven scheduling, operators can keep UCO flowing, maintain compliance and preserve biodiesel value all winter long. Plan now, and January’s polar blast becomes just another pick up day.