*”Carefully consider all options and compare different providers when choosing a used cooking oil storage system. Explore the resources below to gather additional information and compare different perspectives.”

What is UCO? A 30-Second Primer

Used Cooking Oil (UCO) is the liquid gold your fryers produce after cooking. Instead of paying for disposal, restaurants can earn $0.15-0.50 per gallon by recycling it into biodiesel. The key? Choosing the right storage container that matches your volume, space, and budget. Get it wrong, and you’ll waste hundreds annually. Get it right, and you’ll turn waste into profit with minimal effort.

Table of Contents

Regional Rebate Reality Check

Your location significantly impacts UCO economics. Here’s what restaurants are earning in key markets:

Florida: $0.28-0.35/gallon average | Container fees: $35-65/month | Strong year-round demand

Georgia: $0.24-0.31/gallon average | Container fees: $30-55/month | Growing biodiesel market

New Jersey: $0.32-0.38/gallon average | Container fees: $40-75/month | Premium for clean oil

These rates reflect 2025 market conditions. Rural areas typically see 15-20% lower rates due to transportation costs.

Introduction: The Decision That Haunted Mike for Three Years

Mike Rodriguez thought bigger meant better when he chose a 240-gallon UCO container for his 35-seat Mexican restaurant in Austin. His mistake? The oversized container cost him $500 annually in unnecessary fees and degraded oil quality.

His restaurant only generated 45 gallons monthly, leaving the container three-quarters empty between pickups. According to the National Renderers Association, storing oil beyond 30 days reduces its commodity value by up to 15% due to oxidation and contamination. Mike learned this lesson over three expensive years.

The wrong container choice costs restaurants between $200 and $500 annually in inefficiencies. By the end of this guide, you’ll know exactly which container fits your space, volume, and budget – and how to avoid Mike’s costly mistake.

Chapter 1: Your Three Container Options Decoded

The Smart Selection Framework

Choosing the right UCO container isn’t about finding the “best” option – it’s about matching container characteristics to your restaurant’s unique combination of space, volume, and operational needs. The industry offers three primary categories, each solving specific challenges.

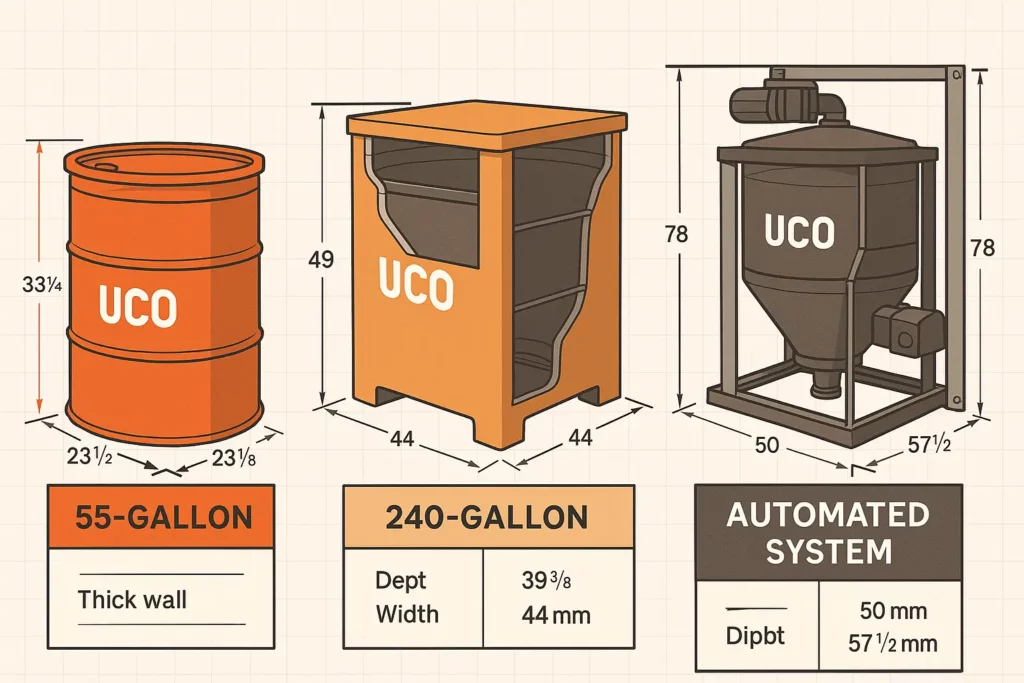

Option 1: 55-Gallon Traditional Containers

The Specs:

- Dimensions: 22.5″ diameter × 34.5″ height

- Footprint: 9 square feet minimum

- Capacity: 55 gallons (220 pounds of oil)

- Typical pickup frequency: Weekly to bi-weekly

Perfect For: Small restaurants (15-40 seats) generating 20-60 gallons monthly with limited outdoor space. The compact footprint fits almost anywhere, from narrow alleys to shared loading areas.

Real-World Application: Tony’s Pizzeria in Brooklyn generates 35 gallons monthly from their single fryer. Two 55-gallon containers cost $40 in monthly rental fees but generate $180 in rebates, netting $140 profit. The flexibility to add a third container during busy seasons sealed the deal for Tony.

Key Advantages: Lower monthly fees ($30-45), maximum placement flexibility, and easy relocation when needed. Budget-conscious operators appreciate the minimal upfront investment.

Trade-offs: More frequent pickups mean additional coordination. Manual handling requires staff attention to prevent overflow. Per-gallon costs increase if containers aren’t filled efficiently.

Option 2: 240-Gallon High-Capacity Containers

The Specs:

- Dimensions: 48″ × 34″ × 72″ (4′ × 3′ × 6′)

- Footprint: 24 square feet minimum plus access

- Capacity: 240 gallons (960 pounds of oil)

- Typical pickup frequency: Monthly

Perfect For: Medium to large restaurants (50+ seats) generating 100+ gallons monthly with dedicated storage areas and steady volume.

The Math That Matters: Fixed monthly fees of $45-75 seem higher than 55-gallon options, but the per-gallon cost actually decreases. A restaurant filling a 240-gallon container monthly pays roughly $0.31 per gallon in fees versus $0.82 per gallon for partially filled 55-gallon containers.

Operational Benefits: Fewer pickups reduce coordination headaches. Larger openings make oil disposal safer for staff. Premium service levels often include flexible scheduling and emergency response.

Space Requirements: Delivery trucks need 12 feet of width and 14 feet of height clearance. Ground must support 1,000+ pounds when full. Some municipalities restrict placement in certain zones.

Calculate Your Monthly Oil Volume in 30 Seconds

Start creating beautiful, fully-customizable websites with the new WordPress Site Editor and the Ollie block theme.

Option 3: Automated Pump Systems

The Technology:

- Indoor caddy: 35-50 gallon capacity

- Outdoor tank: 240-500 gallon capacity

- Automated pump transfers oil on demand

- Remote monitoring prevents overflow

Perfect For: High-volume operations (120+ gallons monthly) with space constraints, premium service needs, or efficiency priorities.

Investment & Returns: Initial installation runs $500-2,000 with monthly fees of $75-150. The EPA estimates automated systems reduce oil-handling labor by 75% while improving oil quality by 20-30% through contamination prevention.

Case Study Results: Downtown Steakhouse implemented automation after struggling with alley access. Results: 80% reduction in staff oil-handling time, zero spill incidents in 18 months, and 25% increase in rebate values from improved quality. ROI achieved in 8 months.

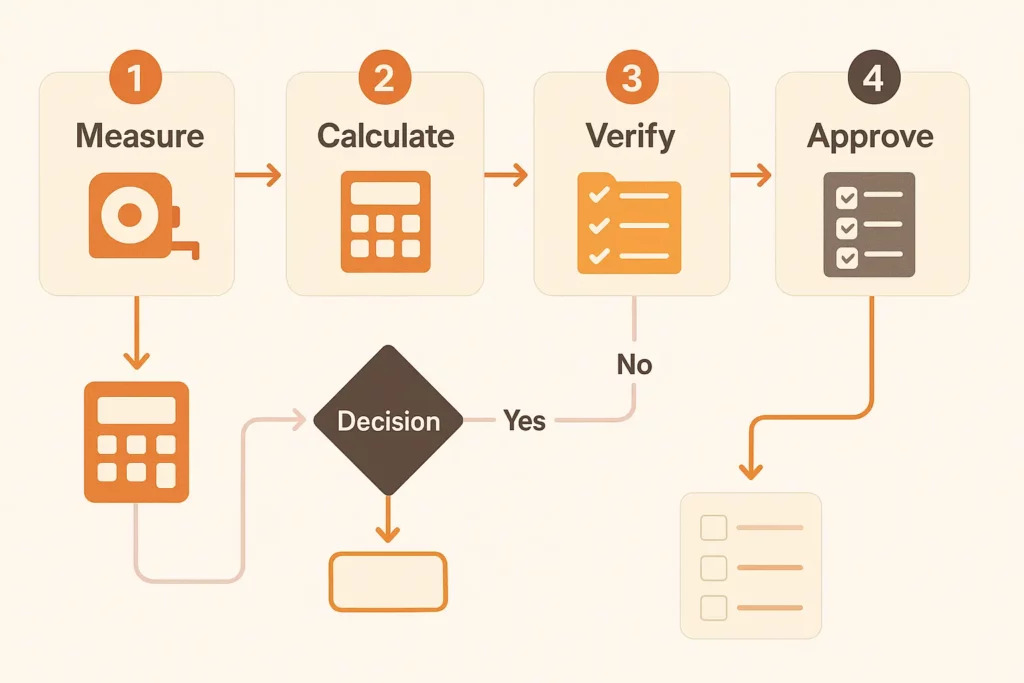

Chapter 2: Your 4-Step Selection Process

Step 1: Space Assessment (5 minutes)

Measure These Dimensions:

- Available ground space (length × width)

- Height clearance for truck access

- Distance from kitchen to container location

- Turning radius for delivery vehicles

Document These Factors:

- Ground condition (concrete, asphalt, gravel, dirt)

- Drainage patterns during rain

- Existing utilities or obstacles

- Security and lighting conditions

Common Mistakes to Avoid: Don’t select summer locations that become inaccessible in winter. Verify landlord approval before assuming placement rights. Consider neighbor complaints about odors or aesthetics.

Step 2: Volume Calculation (10 minutes)

Track for Two Weeks:

- Daily oil disposal amounts

- Oil changes and top-offs

- All sources (fryers, flat-tops, woks)

- Peak vs. average periods

Industry Benchmark: The average full-service restaurant generates 35-70 gallons monthly per fryer, according to the Restaurant Facility Management Association. Adjust based on your menu mix and operating hours.

Seasonal Adjustment Formula: Peak Month Volume × 0.8 = Right-sized container capacity (The 20% buffer prevents overflow while avoiding excess capacity)

Step 3: Total Cost Analysis (10 minutes)

Beyond Monthly Fees, Calculate:

- Pickup charges (if applicable)

- Emergency service fees

- Quality degradation costs

- Staff time for coordination

- Potential contamination penalties

3-Year Comparison Example:

| Container Type | Monthly Fee | Annual Pickups | Other Costs | 3-Year Total | Revenue Impact |

|---|---|---|---|---|---|

| 55-Gallon | $35 | 52 @ $15 | $200 emergency | $2,460 | -$180 quality loss |

| 240-Gallon | $60 | 12 @ $0 | $0 | $2,160 | +$360 quality bonus |

| Automated | $125 + setup | 12 @ $0 | $1,500 install | $6,000 | +$1,080 efficiency gain |

Step 4: Apply the Decision Matrix

If you generate <40 gallons/month: Choose 55-gallon containers

- Low investment matches uncertain volume

- Flexibility for growth or reduction

- Minimal space commitment

If you generate 40-120 gallons/month: Evaluate 240-gallon containers

- Calculate pickup frequency at current volume

- Consider growth trajectory

- Weigh space availability against efficiency gains

If you generate 120+ gallons/month: Consider automation

- Calculate labor savings at your wage rates

- Factor in space constraints

- Evaluate quality improvement potential

Red Flags That Disqualify Providers:

- Won’t specify exact container dimensions

- Vague about total fee structure

- Inflexible pickup scheduling

- No local references available

- Pressure for immediate decision

Quick Implementation Guide

Placement Best Practices

Foundation Requirements: Level surface preventing oil pooling (2% grade maximum). Concrete ideal, compacted gravel acceptable. Avoid areas with standing water or soft soil.

Security Essentials: Motion-sensor lighting deters theft ($50-100 investment). Visible locations reduce vandalism. Locks should be commercial-grade and weather-resistant.

Weather Protection: Simple lean-to structures cost $200-500 but prevent water contamination that can eliminate rebates entirely. Natural building overhangs provide free protection.

Maintenance in Minutes

Weekly (5 minutes):

- Check lid seals

- Verify fill levels

- Inspect for damage

- Note contamination

Monthly (10 minutes):

- Clean surrounding area

- Test lock mechanisms

- Clear drainage paths

- Document oil quality

Seasonal (15 minutes):

- Adjust for weather changes

- Evaluate capacity needs

- Review pickup frequency

- Plan for volume shifts

Your Container Success Starts Now

Mike Rodriguez from our introduction eventually right-sized his container selection, switching to two 55-gallon drums that matched his actual needs. The change saved him $20 monthly in fees while improving oil quality through more frequent pickups. His annual UCO revenue increased by $500 simply by choosing the right container.

Your decision impacts profitability for years. The 30 minutes invested in proper selection prevents years of inefficiency and lost revenue. Unlike many restaurant decisions, container commitments typically last 2-3 years minimum.

Take Action Today

- This Week: Complete your space assessment using our measurement guide

- Next 2 Weeks: Track actual oil volume from all sources

- Week 3: Compare total costs using real data

- Week 4: Contact providers with confidence, knowing exactly what you need

Your Next Step

Download our free Container Assessment Tool that walks you through space evaluation, volume calculation, and cost comparison. This interactive calculator provides customized recommendations based on your specific inputs.

Don’t let container confusion delay your UCO implementation. Whether you need compact 55-gallon drums, efficient 240-gallon containers, or sophisticated automated systems, the right solution exists for your unique situation.

The difference between restaurants profiting from perfect container selection and those losing money to poor choices is simply information and action. Which side will you be on?

Ready to make the right container choice? Try our free Container Assessment Tool and join hundreds of restaurants maximizing UCO profitability through smart equipment selection.

“Disclosure: This page provides information from Grease Connections, a company that offers used cooking oil recycling services. Please be aware that the information may be implicitly biased towards Grease Connections’ solutions. Critical evaluation of the information and consideration of multiple options are encouraged.”

“Additional Resources:

* Used Cooking Oil Management Fact Sheet

* List of UCO Providers

* Waste Management Companies

* U.S EPA Environmental Protection Agency