Not Sure If We Cover Your Location? Check Coverage Here →

Grease Connections Blog

Stay informed with our latest articles and news updates, featuring in-depth analysis and expert commentary.

Popular Topics:

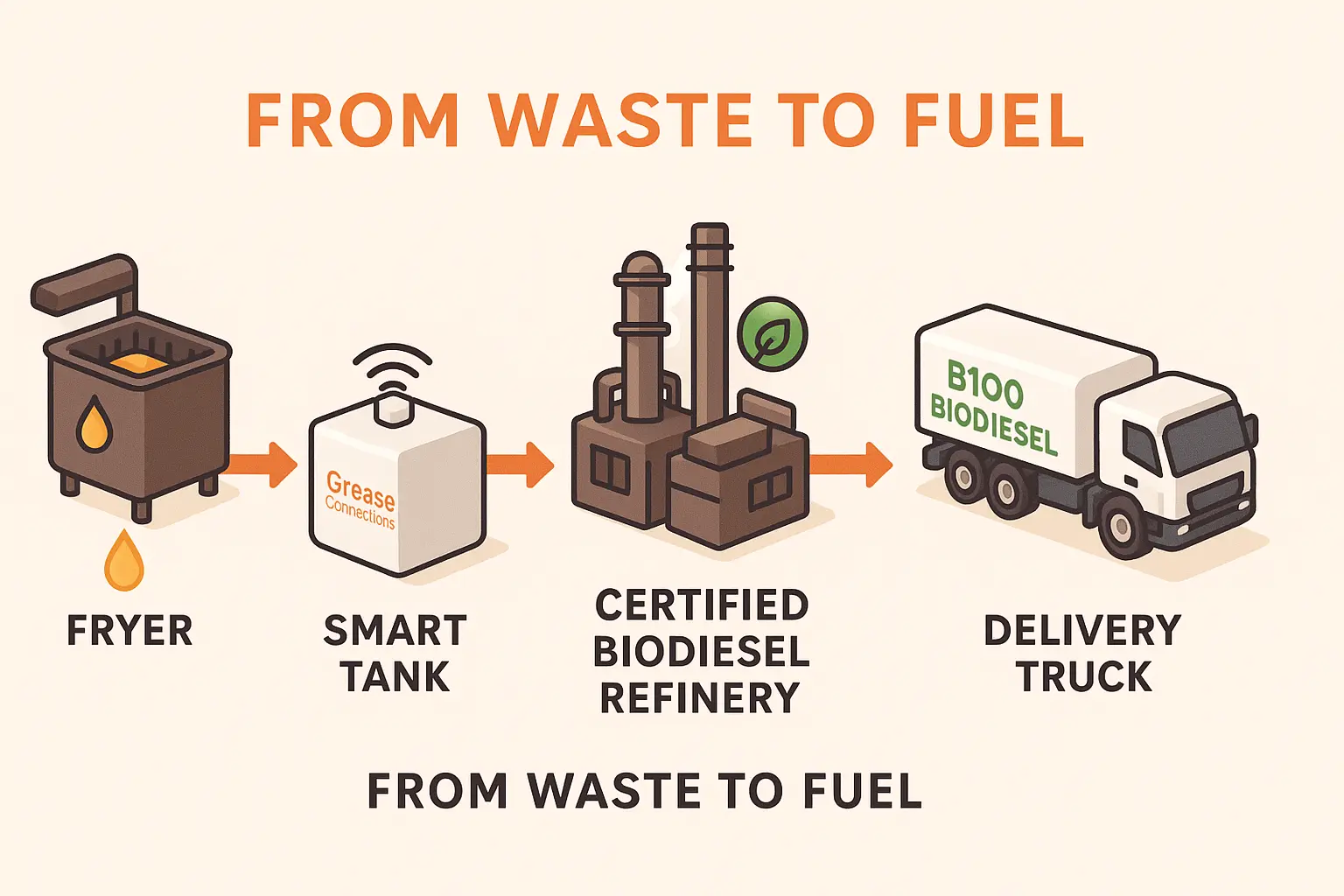

Which Oil Recyclers Make Real Biodiesel?

·

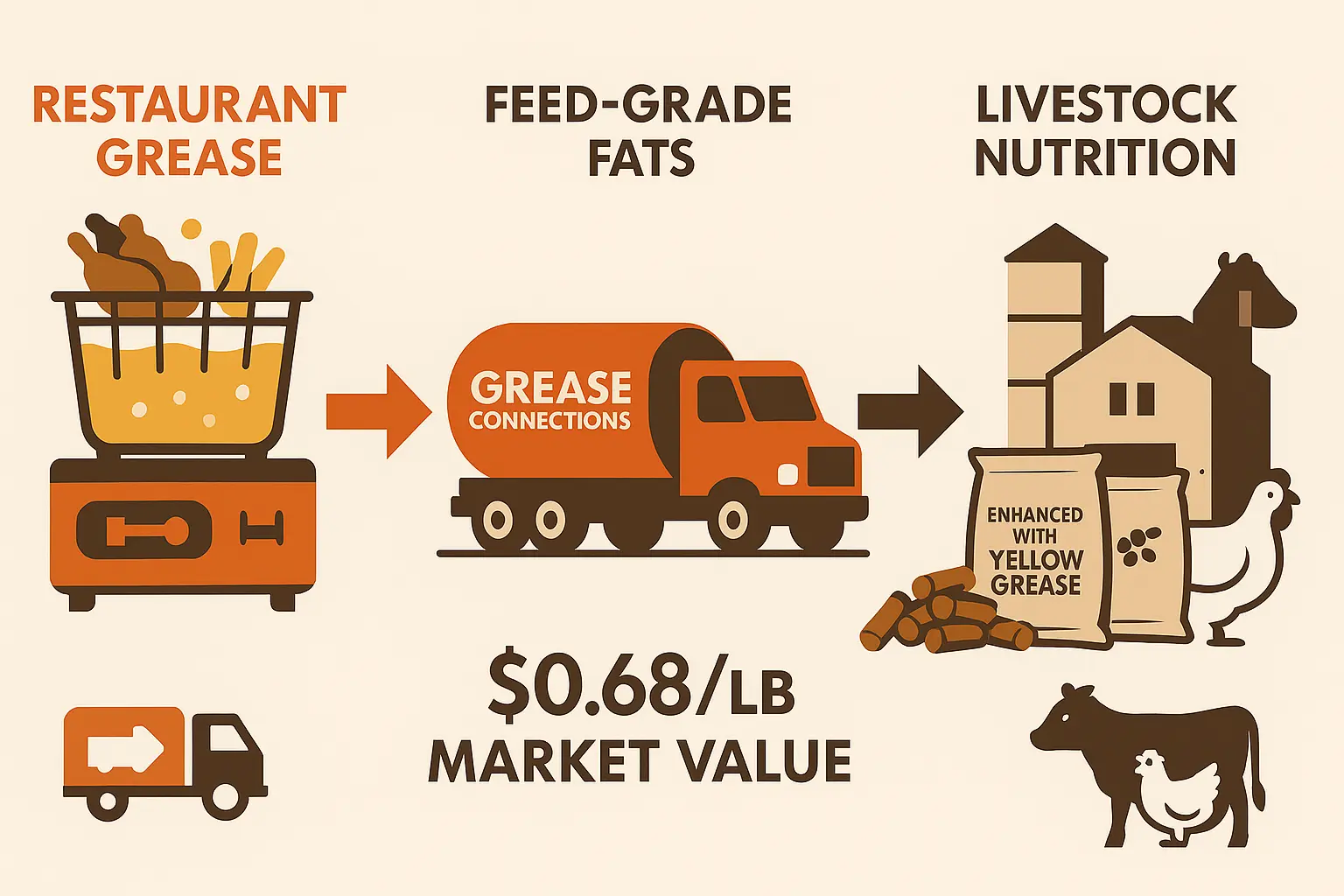

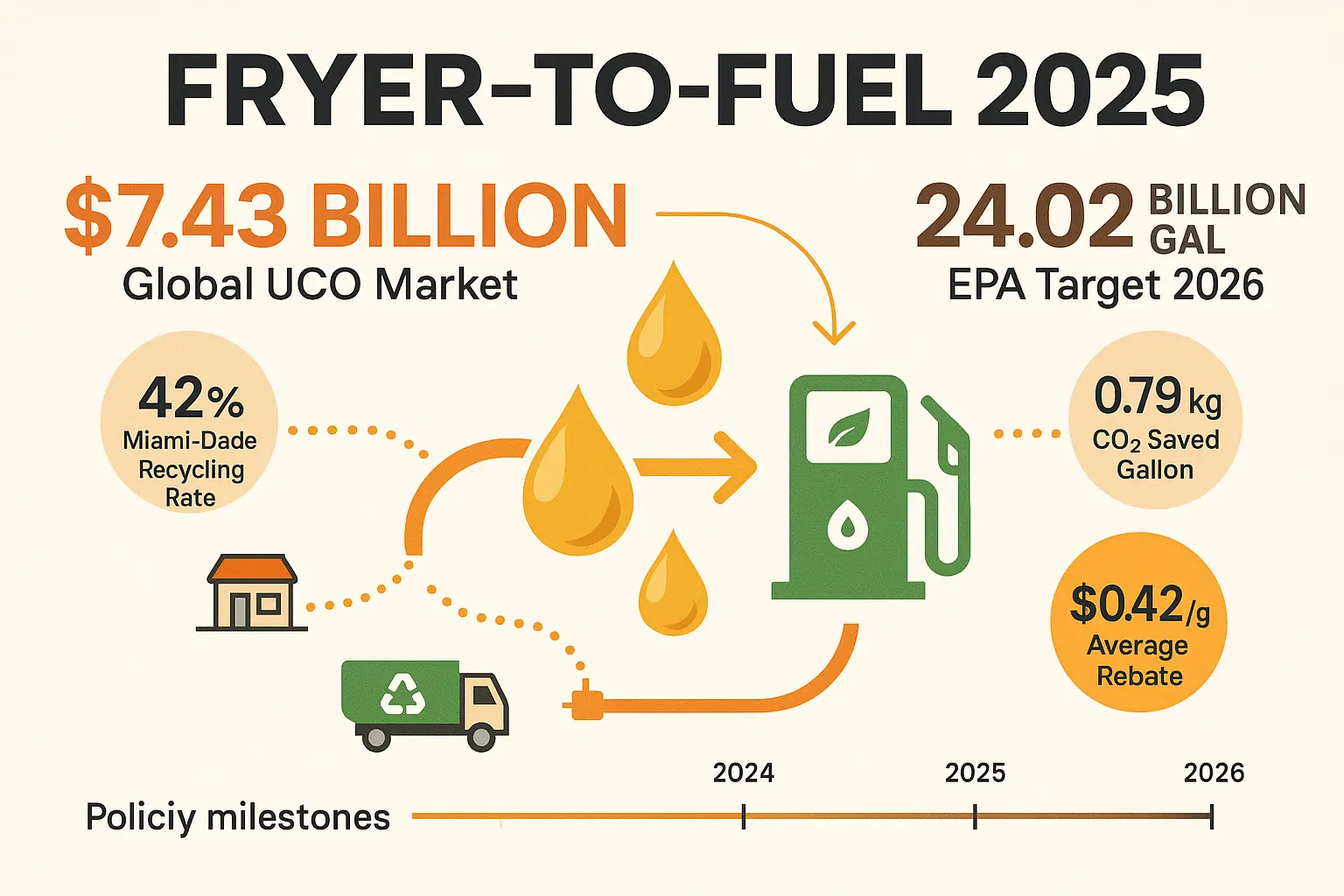

Verified recyclers like Diamond Green Diesel, Neste and Chevron REG turn used cooking oil into low carbon fuel; Grease Connections tracks every gallon to certified plants, eliminating guesswork and greenwash.

Grease Connections provides two hour, 24/7 used oil removal for luxury resorts across key FL, GA, and… Read More

Airlines aim for 10 % SAF use by 2030 and net zero by 2050. U.S. and EU… Read More

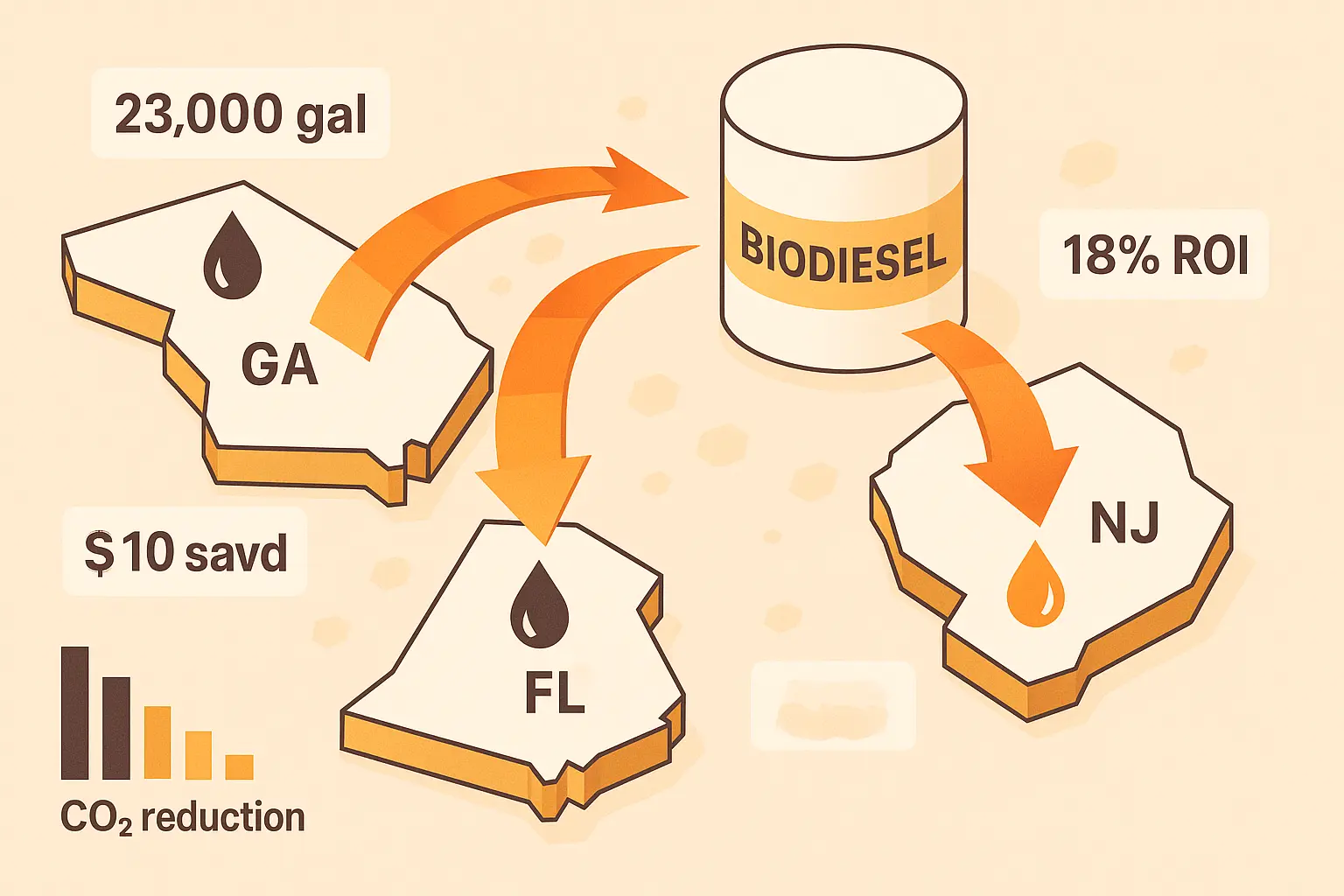

Grease Connections moves 5K plus gallons of used cooking oil for Atlanta restaurants every week, guaranteeing on… Read More

2025 guide shows rebate ranges, state rules, hidden fee traps, and the Grease Connections guarantee for safe,… Read More

Is Cooking Oil Recycling Mandatory? Florida, GA & NJ Rules

·

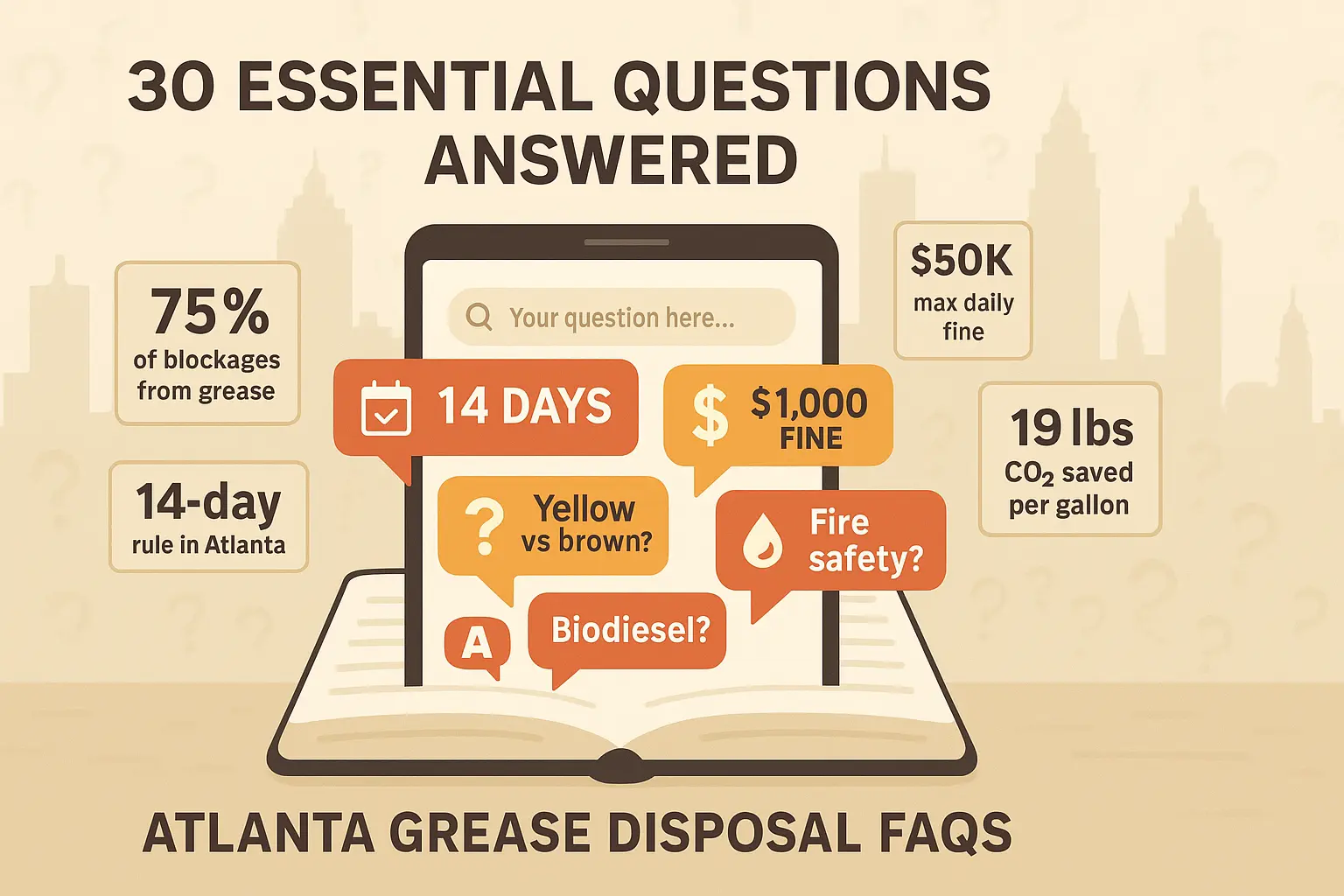

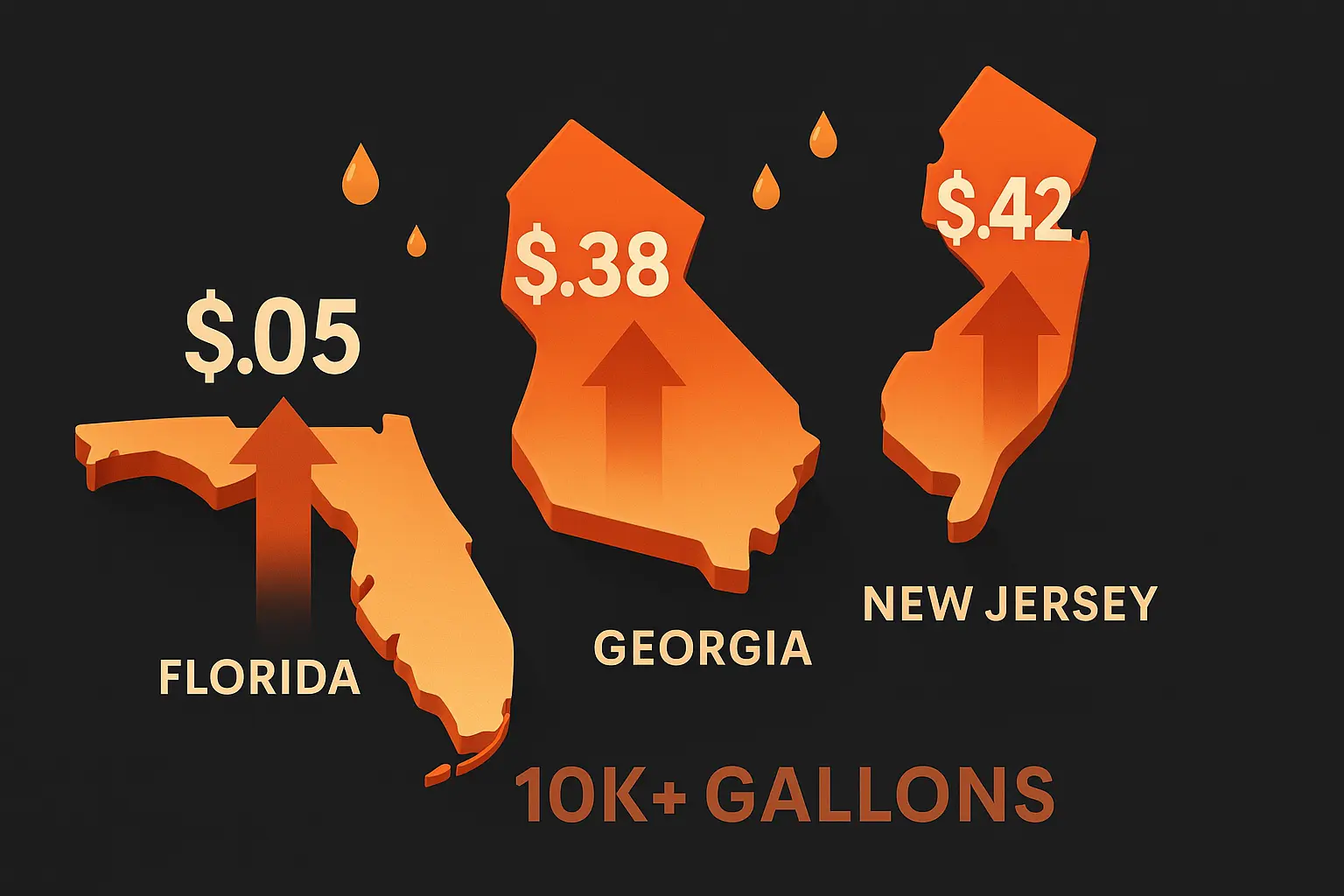

Recycling used cooking oil is mandatory in FL, GA, and NJ. This guide explains the 2025 rules, fines, and a worry free service that pays your penalty if a pickup…

Find vetted 24/7 grease spill responders in Florida, Georgia, and New Jersey, learn the fines for waiting,… Read More

Grease Connections explains how New Jersey restaurants and feed mills turn yellow grease and tallow into animal… Read More

Atlanta restaurants: use this one page checklist to secure permits, pump traps every 90 days, upload manifests… Read More

All your questions answered here in this lengthy Q and A blog post! Read More

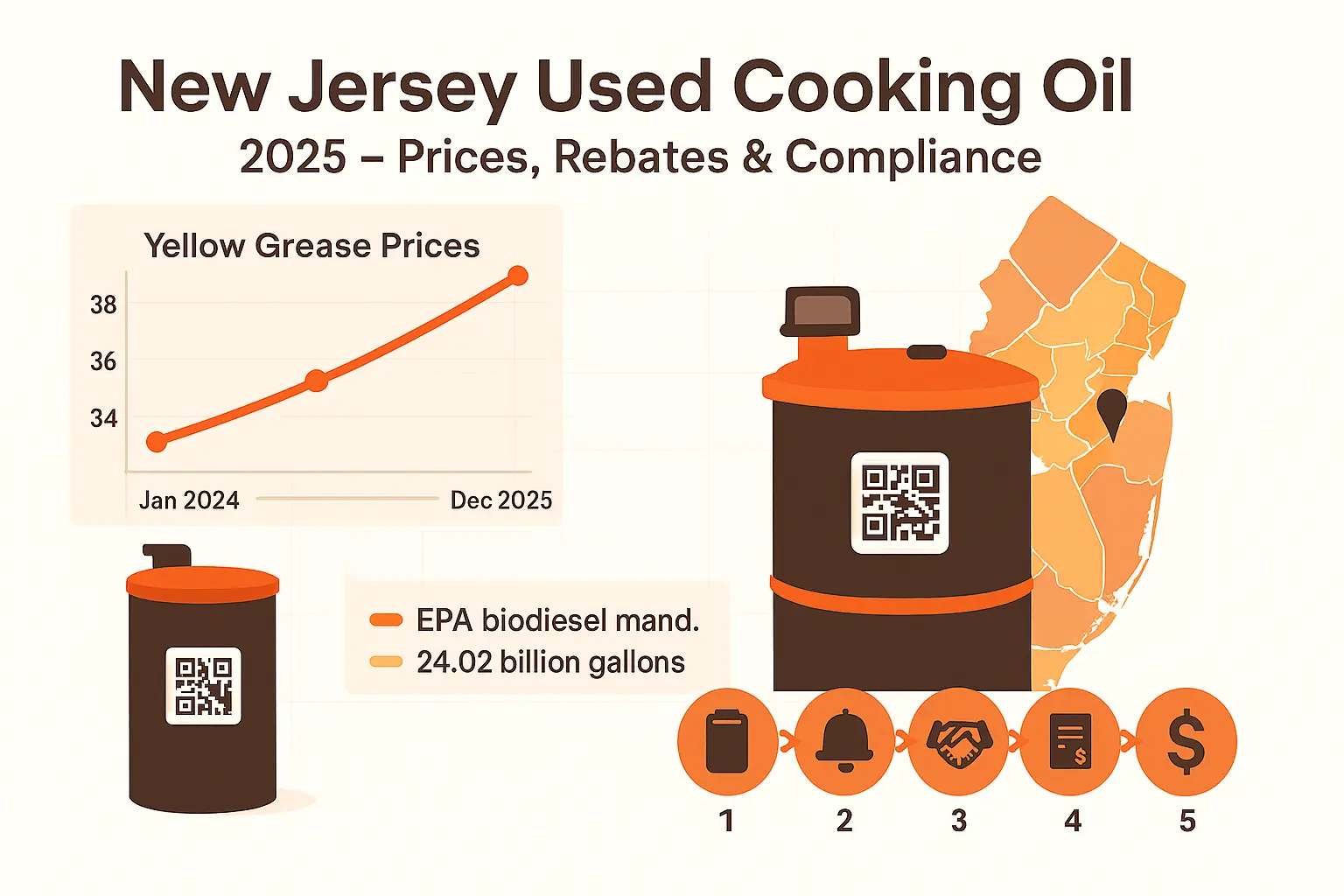

2025 NJ Used Oil Rebate & Price Tracker

·

Live tracker shows 2025 NJ fryer oil rebates, yellow grease prices, biodiesel links, and revenue math, helping restaurants earn more and stay compliant with Grease Connections guidance.

UCO quality, pickup volume, route miles and a partner’s honesty drive your rebate. Clean oil, consolidated loads… Read More

Track live Atlanta fryer oil rebate rates across metro neighborhoods. Access free dashboard, profit forecast calculator, and… Read More

500 gallon campuses earn $0.25 $0.50 per gal by recycling cooking oil. This guide explains rebate math,… Read More

This guide compares leading bulk used oil rebate programs for kitchens producing 10,000+ gallons monthly, reveals hidden… Read More

Oil Collection Companies That Supply Standardized Containers

·

Guide compares top collectors Dar Pro, RTI, Mahoney, Baker, SeQuential, ReGrease who include matching bins or tanks, helping multi location restaurants standardize grease handling and safety.

Grease Connections offers discreet, uniformed used oil pickups after peak hours across FL, GA, and NJ, keeping… Read More

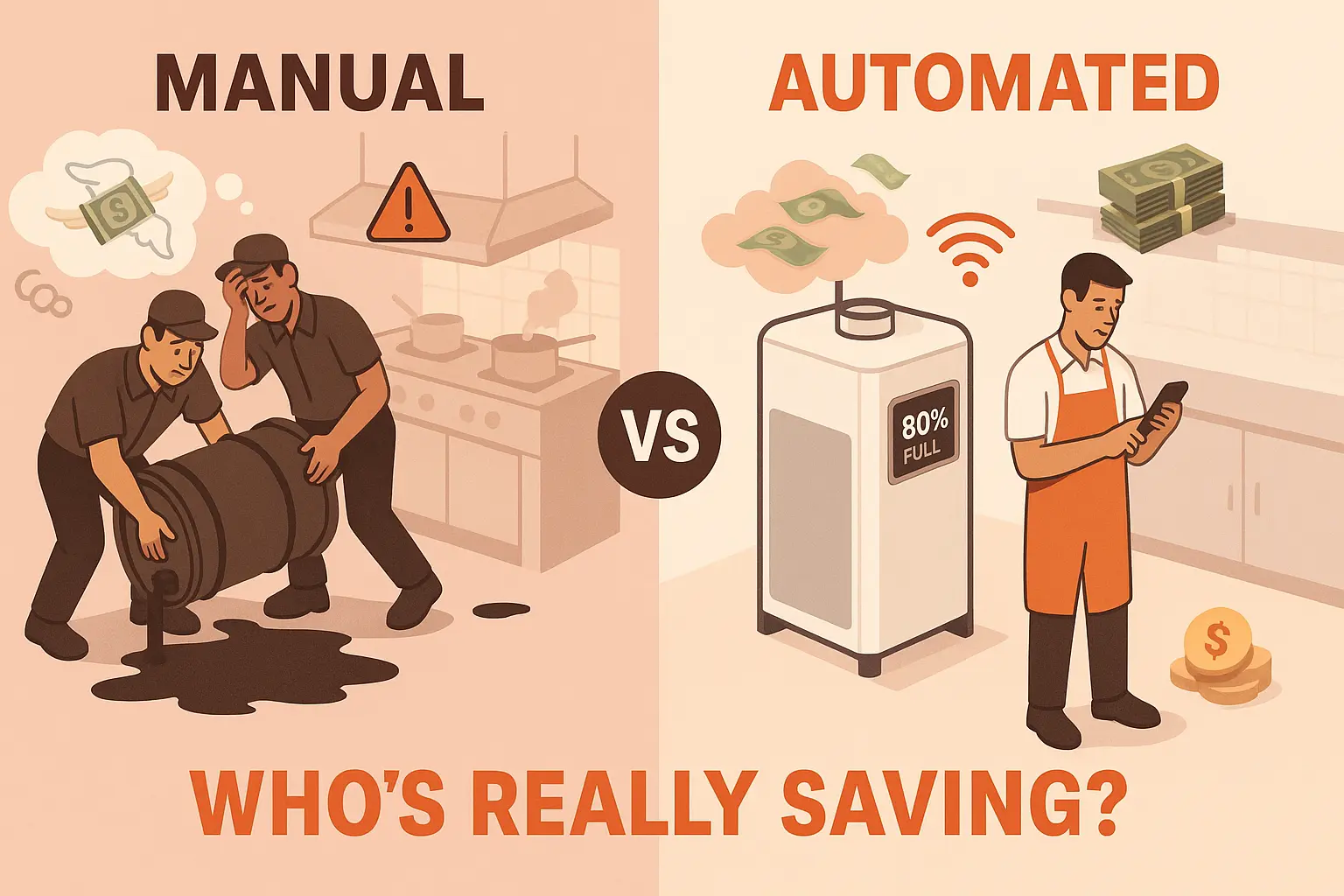

Automated grease systems save high volume kitchens ~65 % in labor, pump out fees, and fines, paying… Read More

Grease Connections’ automated system pairs smart tanks and open APIs with 24/7 dashboards so Florida, Georgia and… Read More

Grease Connections pairs next day oil pickup with open API links to major POS systems and live… Read More

Miami Food Truck Grease Pickup

·

Grease Connections lets Miami food truck fleets schedule compliant grease pickup 24/7, preventing $250 FOG fines and earning fast rebates through hurricane rated containers and a mobile portal.

Grease Connections pairs next day oil pickup with open API links to major POS systems and live… Read More

This guide compares leading bulk used oil rebate programs for kitchens producing 10,000+ gallons monthly, reveals hidden… Read More

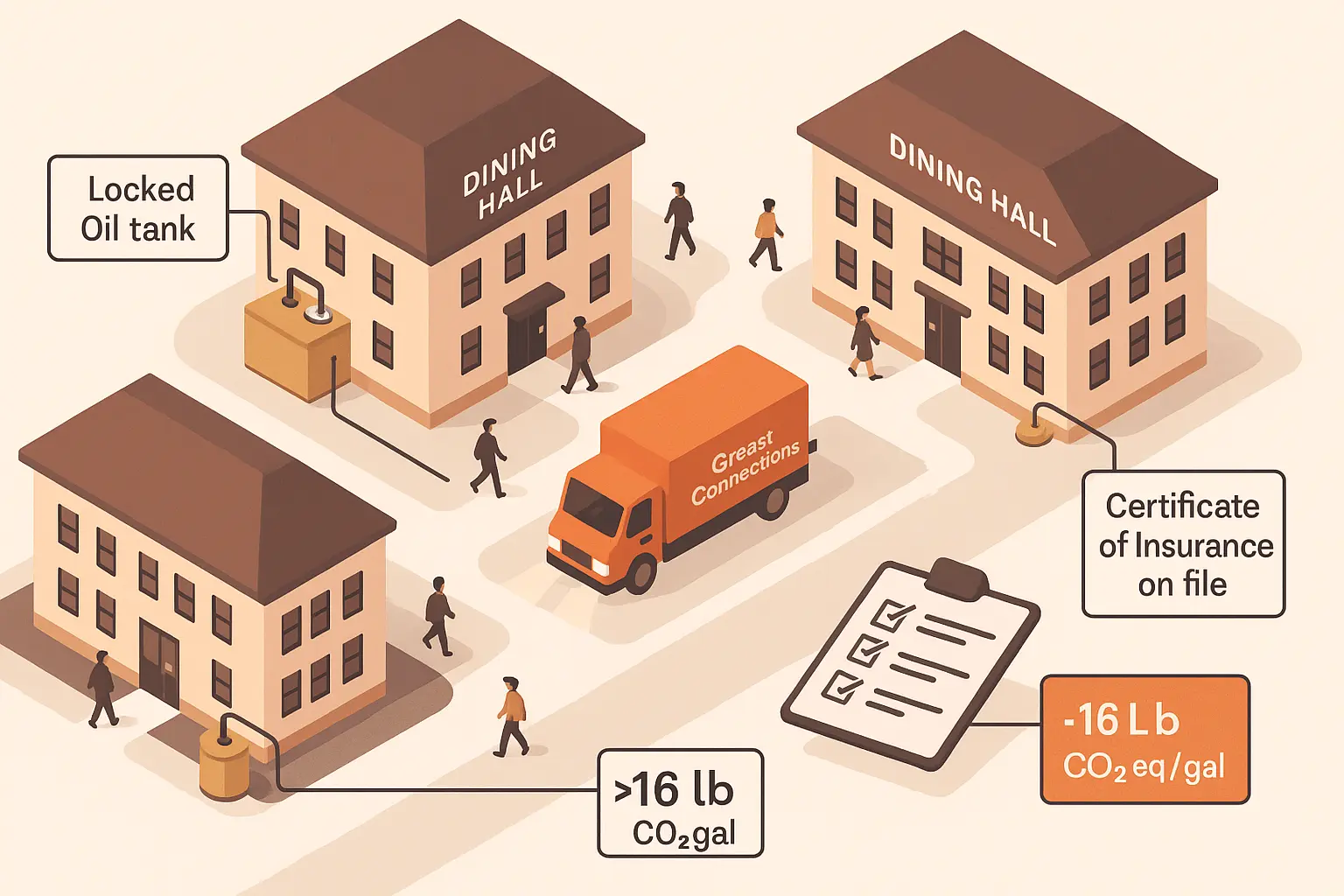

How three dining halls serving 5 000+ meals daily secure insured, on schedule used oil pickups across… Read More

Find out which grease firms give you one monthly report and why Grease Connections tops them all… Read More

Long Term Effects of Cooking Oil Pollution

·

Cooking oil pollution leaves dead zones, soil damage, fatbergs, and costly repairs that linger for decades. Learn the science, real costs, recovery timelines, and how Grease Connections’ 24/7 monitored program…

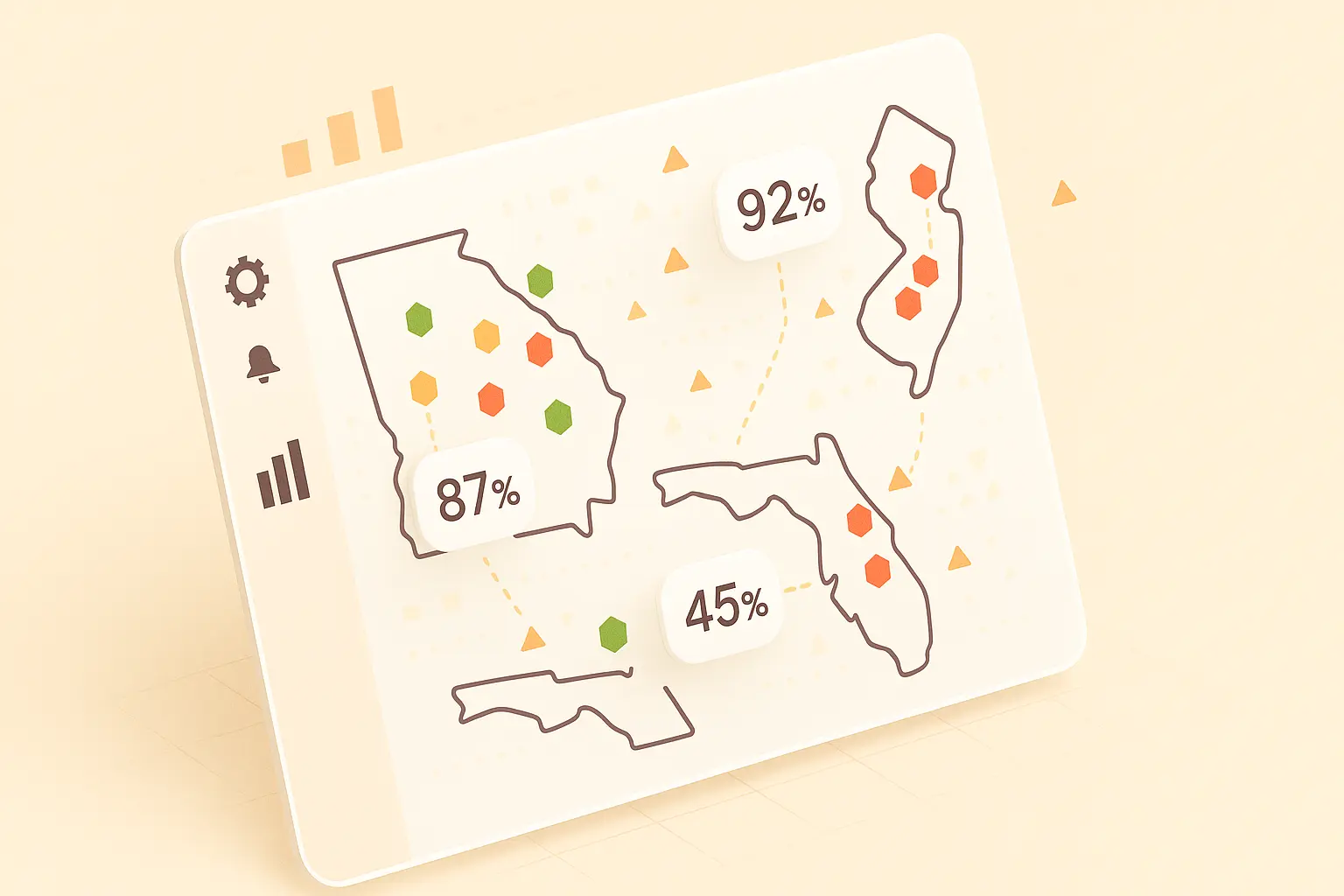

Comprehensive 2025 analysis of used cooking oil recycling across six key counties. Explore market volumes, rebate rates,… Read More

Transform Atlanta’s 12 million gallons of annual fryer oil into revenue. Complete guide to Fulton County compliance,… Read More

Live tracker shows 2025 NJ fryer oil rebates, yellow grease prices, biodiesel links, and revenue math, helping… Read More

Find vetted 24/7 grease spill responders in Florida, Georgia, and New Jersey, learn the fines for waiting,… Read More