Table of Contents

Why Today’s Jet Fuel Has a 50 % SAF Ceiling

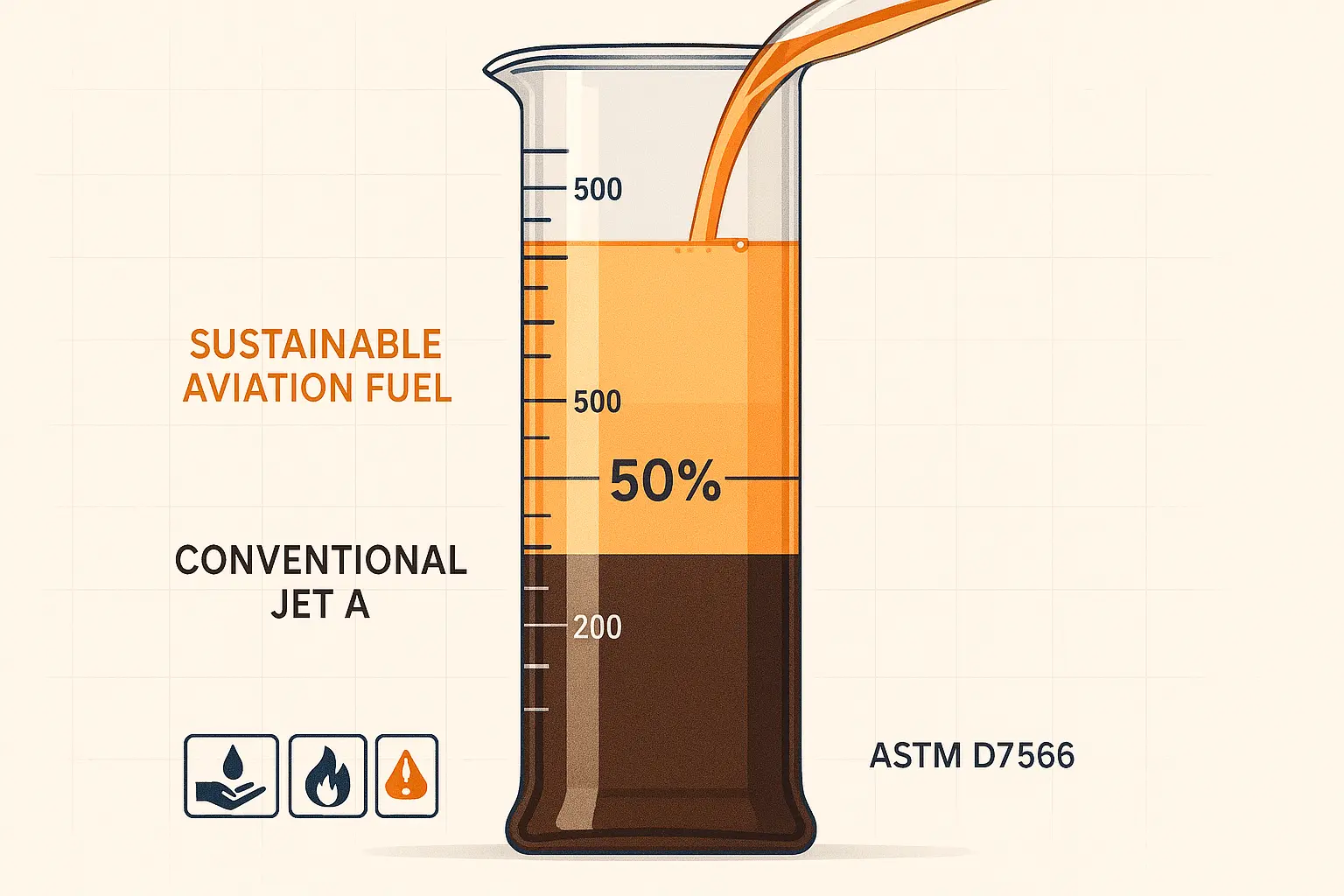

Ask any pilot about the SAF blending ratio and you’ll hear “no more than a 50 % SAF blend.” According to the U.S. Department of Energy, every ASTM approved pathway from HEFA SPK to FT SPK stops at that halfway mark. The Federal Aviation Administration echoes the rule, noting blend limits “capped at 50 %” for all commercial use. In practice, airports receive pre blended fuel so nothing changes at the wing. For restaurants eyeing SAF markets, this ceiling shapes demand for the yellow grease you recycle with us.

How ASTM and FAA Write the Fine Print

In aviation, sustainable aviation fuel regulations live inside ASTM D7566 and D1655, the gold standard tests for “drop in” quality. This is the heart of ASTM SAF blending: once synthetic fuel passes D7566, it must be blended, then recertified as Jet A under D1655 before take off. The FAA verifies that each batch meets those jet fuel blending requirements. Because ASTM keeps updating annexes, new feedstocks (corn ethanol ATJ in 2023, for instance) gain approval without rewriting the whole spec.

Neat SAF Trials Point Toward a Higher Maximum

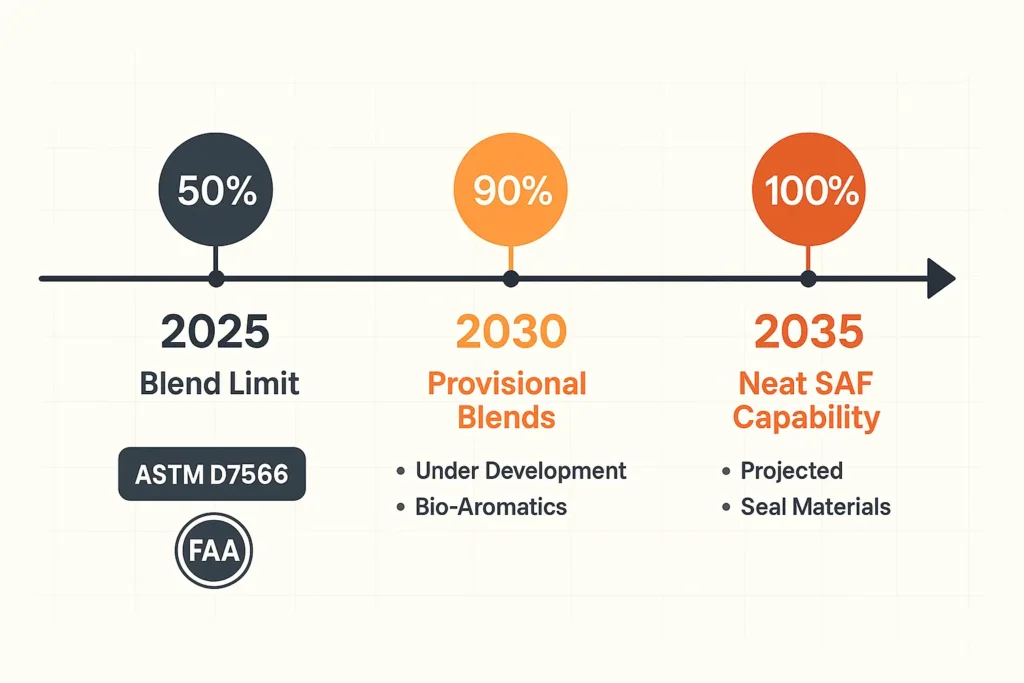

Engineers call 100 % fuel “neat SAF.” Boeing, Airbus, and United Airlines have already flown on it, gathering data on the next maximum SAF blend. On a 2021 United flight, one 737 MAX engine burned 100 % drop in SAF, while the other ran conventional fuel to prove parity. Airbus followed in 2024 with contrail reduction studies using 100 % SAF. Although passengers barely noticed, regulators still require the 50 % cap until material compatibility studies finish.

Aromatics, O Rings, and Seal Safety: Why Is SAF Blended?

So why is SAF blended at all? Classic Jet A carries 15 to 20 % aromatics that swell nitrile O rings, preventing leaks. Most SAF is paraffinic and nearly aromatic free. Lab work shows seals may shrink if aromatics drop below about eight percent, risking drips at altitude. Blending with petro fuel re introduces enough aromatics to hit that safety window, setting the hard SAF blend limit. Scientists are now testing bio aromatic additives so tomorrow’s 100 % SAF stays leak tight.

Policy Heat Map: CORSIA, ReFuelEU, and U.S. Goals

Globally, the ICAO’s CORSIA SAF requirements say any SAF used for carbon credit relief must meet ASTM specs and deliver at least 10 % life cycle CO₂ savings. Europe’s ReFuelEU law starts at a two percent blend in 2025, climbing to 6 % in 2030 and 70 % by 2050, all while certified only up to 50 % today. The U.S. SAF Grand Challenge aims for three billion gallons by 2030, but it keeps the same 50 % rule until ASTM revises D7566. For fleet managers, these mandates drive steady demand for waste oil feedstocks that can meet the carbon scorecard.

| ASTM Approved Pathway | Year Approved | Typical Feedstock (incl. used cooking oil) | Blend Limit |

|---|---|---|---|

| HEFA SPK | 2011 | Yellow grease, tallow | 50 % |

| FT SPK | 2009 | Forest waste, MSW | 50 % |

| ATJ SPK (ethanol) | 2018 | Corn stover sugars | 50 % |

| HFS SIP | 2014 | Cellulosic sugars | 10 % |

| HC HEFA (algae) | 2020 | Algal oils | 10 % |

From Fryer to Flight: Your Action Checklist

If you oversee a restaurant, the grease going into our trucks could power jets tomorrow. First, confirm your oil reaches an RFS registered processor; that paperwork is essential when airlines claim SAF credits. Second, track sulfur and water content as tight specs fetch premium prices. Finally, consider a long term contract with our Miami used cooking oil collection service to lock in volumes before blend mandates climb. Your kitchen waste may be a small stream, but multiplied across thousands of eateries, it fills the tanks that keep U.S. aviation on schedule.

| Year | EU Mandate | U.S. Target | Certified Blend Cap |

|---|---|---|---|

| 2025 | 2 % | — | 50 % |

| 2030 | 6 % | 3 Bn gal SAF | 50 % |

| 2050 | 70 % | 35 Bn gal SAF | TBD (goal: 100 %) |

Sources: EU ReFuelEU, DOE Grand Challenge

Roadmap to Higher Ratios

ASTM’s task force is isolating the exact seal swell chemistry to rewrite D7566 for “drop in 100 % SAF.” Airlines expect provisional 90 % blends within five years, followed by full approval once bio aromatic additives prove field durability. Industry partnerships like Boeing’s bio aromatic R&D cited above suggest commercial flights on fully synthetic kerosene by early 2030s, pending supply scale up and cost parity. Until then, the reliable SAF blending ratio remains 50 50; every gallon of clean fryer oil you divert keeps that pipeline flowing.

Key Takeaway

The 50 % limit is a safety lock, not a technical dead end. By tackling aromatics, seal materials, and clear policy incentives, the industry is already prying that lock open, one recycled gallon at a time.