Table of Contents

Why Fish Oil & FOG Control Matters on NJ’s Docks

New Jersey lands more than 100 seafood species and ships through six major ports, including Cape May, Barnegat Light, Atlantic City and Port Norris. The state’s 15 processors turn that catch into fillets, surimi and fishmeal leaving behind oily stick water that can hit 2,000 mg/L FOG and 15,000 mg/L COD if untreated.

When that mix slips into public sewers it clogs pumps, starves oxygen in estuaries and can trigger five figure fines. Phillipsburg’s ordinance alone levies up to $250 per annual inspection plus penalties for failed tests. Staying ahead means pairing good housekeeping with tech that captures sellable fish oil turning waste into revenue and goodwill.

From Cape May to Barnegat Light: How Plants Create High Strength Wastewater

Cape May’s Lund’s Fisheries handles up to 85 million lb of seafood a year, unloading 15 vessels daily. Barnegat Light’s Viking Village adds scallops and monkfish to the mix. Each filleting table, skinning drum and blast freezer rinses oils into floor drains. During peak scallop shucking, oily foam from “stick water” separators can spike, while grinders that mince crab shells add solids.

EPA studies show fish plant BOD mirrors domestic sewage but FOG is drastically higher, overwhelming POTWs. Understanding these streams lets plants batch tank high oils rinse water, slashing surcharge bills.

NJ Rules & Permits: What You Must Navigate

- NJDEP Pretreatment: Local limits cap animal & vegetable oil discharge; POTWs levy annual FOG inspection fees of $90 to $250.

- NSSP Shellfish Sanitation: Processors of clams, oysters and crabs must keep grease systems from cross contaminating product contact areas and maintain HACCP records.

- City Ordinances: Cape May County MUA requires high strength users to pretreat before releasing to its 31 MGD system.

- FOG Local Laws: Phillipsburg and other town codes ban any discharge over 100 mg/L oil & grease without a variance.

Keep copies of your wastewater permit, grease trap pump out logs and NJDEP “No Exposure” storm water certificate where inspectors can see them.

Proven Separation Tech That Pays for Itself

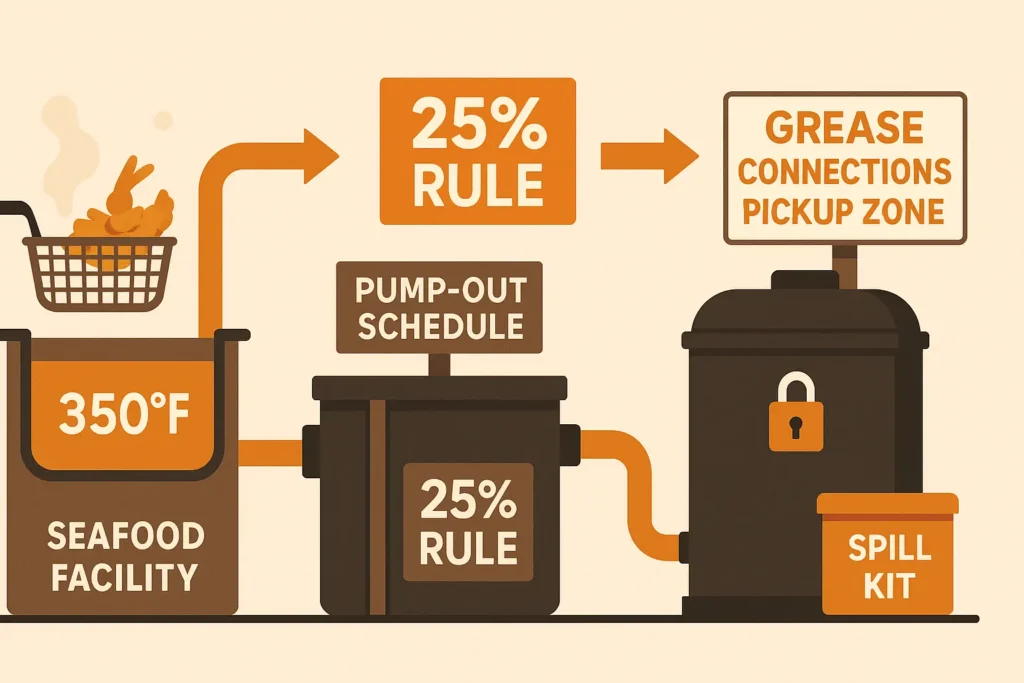

Three phase decanter centrifuges skim oil, water and solids in a single pass, recovering food grade fish oil at up to 25 m³/h. Plants that add dissolved air flotation (DAF) cut residual FOG to < 30 mg/L before sewer discharge. Alfa Laval and Flottweg report ROI in under 18 months when stick water is sold to Omega 3 blenders. For smaller crab picking houses, a 500 gal cone bottom tank and portable skimmer meet the 25% rule for pump outs.

Daily Practices that Keep Drains Clear & Inspectors Happy

- Warm Water Pre Rinse: 120 °F keeps fish proteins fluid without cooking them onto pipes.

- “Dry Scrape” Floors First: Removing scales and viscera with squeegees reduces BOD by up to 35 %.

- Log Every Pump Out: NJ inspectors ask for 3 year manifests during audits; Grease Connections emails PDFs automatically.

- Test Quick Dip Fat Strips Weekly: Allows early trap clean outs before exceeding the 25 % threshold.

- Rotate Spill Kits: Store fiber pads and hydrocarbon boom at every doorway; replace quarterly per EPA seafood taint guidance.

Spill & Leak Response: Five Minute Clock

A ruptured fish oil line can slick a cold storage dock fast. New Jersey spill law demands oral notice to 1‑877‑WARN‑DEP within 15 minutes if oil threatens surface water. Draft your one page plan:

- Hit Emergency Shut Off on pumps.

- Ring Grease Connections 24/7 line vacuum tanker arrives within four hours statewide.

- Deploy Absorbent Boom around floor drains; double bag saturated pads.

- Document With Photos for insurance; log volume lost.

- File Written Report to NJDEP within five days.

- Follow up ATP swabs confirm seafood isn’t tainted before re opening pack lines.

The Grease Connections Blueprint for NJ Seafood Plants

Grease Connections is the only used oil collection company with a dedicated seafood processor program: vacuum tankers rated for food grade oils, trap clean crews trained under NSSP, and smart sensors that ping our dispatch when your tank hits 70 %. We serve Cape May, Atlantic City, Newark, Jersey City, Elizabeth, Toms River, Trenton and Paterson on fixed routes, so pickups sync with your production cycles. Our manifest emails satisfy both NJDEP and FDA auditors, and recovered fish oil flows into certified biodiesel closing the loop.

Key NJ Ports & Permit Authorities

| Port / City | Anchor Processor | Primary Permit Office |

|---|---|---|

| Cape May | Lund’s Fisheries | Cape May MUA Pretreatment |

| Barnegat Light | Viking Village | Long Beach Township Utilities Dept. |

| Atlantic City | Atlantic Capes Fisheries | ACUA Industrial Pretreatment |

| Newark/Elizabeth | Multiple cold storages | PVSC Pretreatment (FOG fees) |

Delivering fish oil recovery expertise, real NJ regulations and proven tech in one place bookmark it, print it, share it with your plant team, and call Grease Connections before the next boat ties up.