Table of Contents

Summary

Used cooking oil spoils when oxygen, heat, water, and light trigger oxidation, hydrolysis, and polymerization. According to peer reviewed studies and fire protection codes, rancid oil not only ruins flavor but also raises free fatty acid (FFA) and total polar materials (TPM) levels, lowers flash points, and turns storage areas into fire and pest magnets. This guide explains the chemistry, early warning signs, legal thresholds, and step by step prevention tactics, backed by EPA rules, NFPA standards, and current industry best practice, to help you store, monitor, and recycle oil safely and profitably.

The Chemistry Behind Spoilage

Triglycerides break down in three main ways: oxidation (oxygen attacks double bonds), hydrolysis (water splits ester bonds), and thermal polymerization (molecules link into gums), reactions that accelerate every 10 °C, roughly doubling in rate, according to kinetic “rule of thumb” data. Elevated temperatures in fryer rooms, metal ions, and UV light form aldehydes and ketones that give rancid oil its acrid smell.

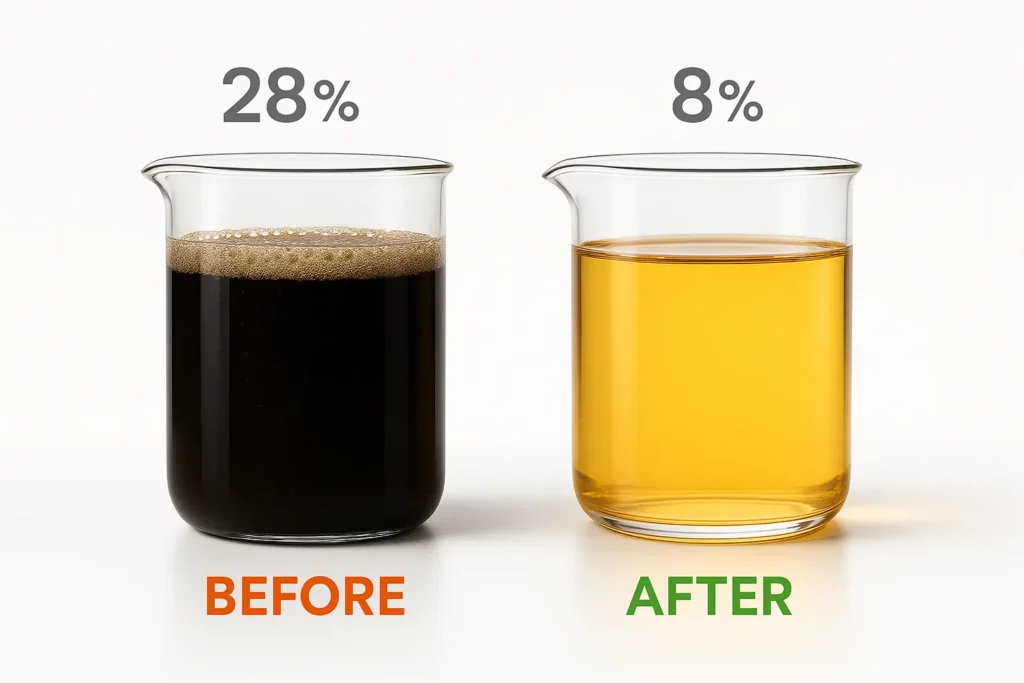

Visual, Smell & Performance Clues

A sour or metallic odor, darker hue, persistent foam, and thicker “sticky” feel mean oxidation products are climbing. According to SaveFryOil’s quality checklist, any off smell is an immediate red flag. Food tasting bitter after frying is another late stage cue noted in a peer reviewed rancidity survey. Grease Connections adds that cloudy oil or rapid smoking also signal spoilage.

Hidden Safety & Cost Hazards

Once TPM tops 24 to 25%, flash points fall and the oil becomes easier to ignite, increasing grease fire risk, according to NFPA 30 storage guidance and European TPM legislation. Spoiled oil absorbs more heat, forcing fryers to cycle longer and hike energy use. Sticky polymers clog filters and exhaust hoods, multiplying NFPA 96 cleaning costs.

Environmental Triggers in Your Storeroom

Heat is the primary catalyst; every 10 °C rise doubles oxidation rate, making rooms above 25 °C risky. Light exposure creates free radicals, while oxygen seeping past loose lids fuels hydroperoxide formation. According to EPA used oil guidance, containers must be “in good condition and closed” to slow these reactions. Humidity or fryer condensate drives hydrolysis, and iron or copper taps accelerate polymerization.

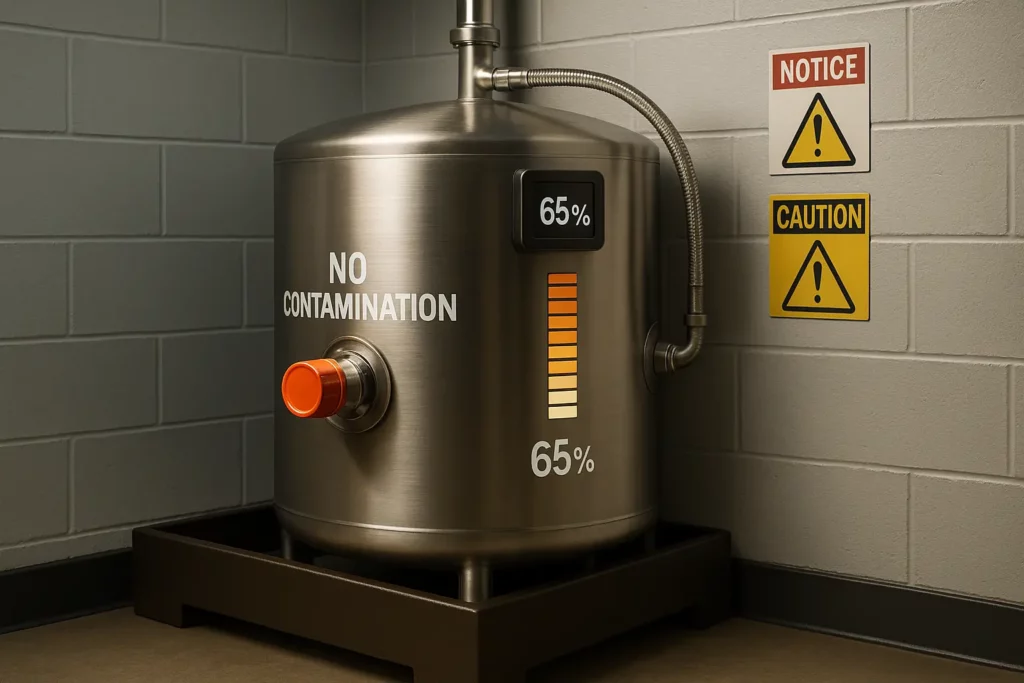

Choosing the Right Storage Hardware

Dark, food grade, welded steel or high density polyethylene tanks shield oil from light and rodents. Restaurant Technologies’ indoor and outdoor units use opaque walls and leak proof quick connects to block air and UV. Under the 2015 IFC §610, tanks must be UL listed, fitted with level gauges, and positioned away from ignition sources. For high volume sites, Grease Connections recommends automated 140 to 300 gallon systems that pump directly from fryers, eliminating messy “drag and dump” barrels.

Daily Monitoring & Quality Benchmarks

Quick read FFA strips and handheld TPM meters give objective discard calls in under 30 seconds. According to Oklahoma State University Extension, frying oils with >2% FFA should be replaced or blended down. Many chains adopt 24% TPM as their absolute limit.

| Quality Metric | Discard Threshold | Reason |

|---|---|---|

| Free Fatty Acids (FFA) | > 2% | Off flavors, soapiness |

| Total Polar Materials (TPM) | ≥ 24 to 25% | Toxic polymers, lower flash point |

| Smoke Point Drop | ≥ 50 °C loss | Volatile aldehydes escalate |

Training & Compliance Protocols

Label every tank “Used Cooking Oil: Food Waste” per EPA rules and post NFPA 96 cleaning logs near the fryer station. Staff should cool oil to <60 °C before transferring, wear gloves and goggles, and verify vent caps are clear, as UL notes tanks need both normal and emergency vents. Monthly self audits: temperature mapping, lid integrity, spill walk through, keep insurers satisfied and prevent costly code citations.

Closing the Loop: Recycling & ROI

Sealed, contaminant free oil fetches higher rebates from biodiesel collectors and lowers carbon footprints. Grease Connections reports that smart filtration plus closed loop pick ups can cut fryer spend by 50% while meeting sustainability KPIs. Separate water or food scraps before the hauler arrives; fines for adulterated loads now exceed disposal savings in many states.