Table of Contents

Why Grease Is the New Gold in Orlando

Every day local kitchens pour hundreds of gallons of leftover frying oil down the drain. That waste once choked sewers and drove up maintenance bills; now it powers garbage trucks and utility pickups. Since 2015 the City of Orlando’s recycling initiative has diverted thousands of gallons of fats, oils, and grease (FOG) into a circular-economy fuel stream, positioning the city as a Southeastern leader in municipal biofuels. Understanding the science and the community partnership behind it shows why “grease for diesel” is more than a clever slogan; it is critical climate infrastructure that keeps tourism buses moving and waterways clear. Over the next few sections we trace that journey from skillet to fuel tank and show you how to plug in.

Step 1: Citywide Collection That Starts in Your Kitchen

The process begins the moment cooking oil cools. Residents pour up to two gallons into any shatter proof jug, seal it, and drop it at one of a dozen neighborhood centers or participating fire stations. Restaurants enroll in the Grease Management Program, receive leak proof bins, and schedule free pickups that match their peak service hours. Used cooking oil recyclers such as Grease Connections consolidate loads at depots on the city’s industrial fringe before delivering the bulk oil to a preprocessing facility. Clear signage, online maps, and text alert reminders keep participation friction free, an important ranking factor for searchers seeking “easy cooking oil drop off Orlando.”

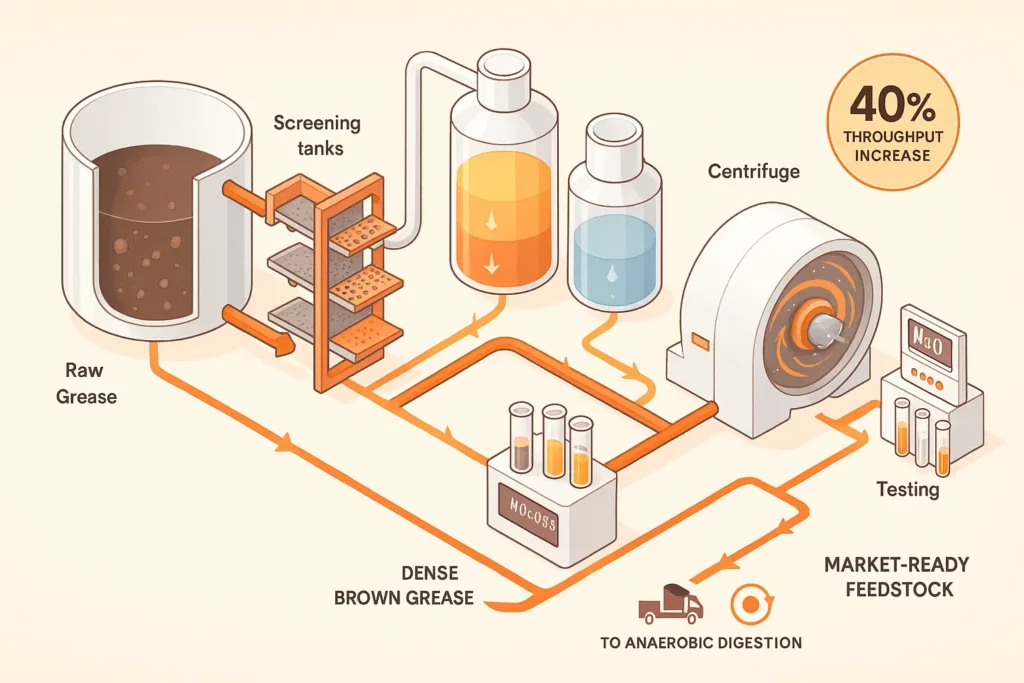

Step 2: Filtering, Dewatering, and FOG Separation

Raw grease arrives full of food particles and water, two impurities that would foul diesel engines. Operators pump the oil through screens, settle tanks, and a centrifuge that spin out crumbs and moisture. New Greasezilla® units slated for 2025 will boost throughput by 40 percent while generating a dense brown grease by product sold to anaerobic digestion plants. When testing confirms water content below 0.05 percent, the cleaned “yellow grease” is ready for chemistry. This intermediate product is already marketable as feedstock, but Orlando keeps the added value local by finishing the fuel in house.

Step 3: Transesterification: Chemistry That Makes Diesel from Doughnuts

In stainless steel reactors, technicians blend the filtered oil with methanol and a tiny amount of potassium hydroxide. The catalyst breaks the triglyceride molecules, swapping their glycerol backbone for methyl esters, the molecules we call biodiesel. A 20 minute reaction at 60 °C converts roughly 100 pounds of grease into 100 pounds of biodiesel and 10 pounds of marketable glycerin. The biodiesel is then washed, dried, and polished until it meets every parameter of ASTM D6751, from flash point to cloud point. Quality control is strict because B20 blends go straight into heavy duty refuse haulers that can’t afford mid route downtime.

Step 4: Blending, Storage, and Local Distribution

Finished B100 biodiesel is cooled, gravity fed into double walled day tanks, and blended on demand with ultra low sulfur diesel to create B20 or B30. Orlando Utilities Commission fuels more than 900 vehicles from two 10,000 gallon biodiesel islands at Pershing and Gardenia depots, logging over four million road miles since rollout. Because biodiesel has a naturally higher cetane number, mechanics report smoother cold starts and no performance loss. The city tracks every gallon through a cloud based fuel management system that also supplies data for its public sustainability dashboard, transparency that search engines and residents both reward.

Tangible Benefits: From Carbon Cuts to Clean Sewers

Converting waste grease to fuel reduces lifecycle greenhouse gas emissions by up to 86 percent compared with petroleum diesel, according to the U.S. Department of Energy. Locally, the city has slashed sewer overflows linked to FOG blockages by 30 percent since launching the program. Restaurants avoid costly plumbing backups, taxpayers save on sewer maintenance, and new green collar jobs appear in logistics, lab testing, and plant operations. Even the glycerin co product finds a second life in Central Florida soap manufacturing, completing the zero waste loop.

How Residents and Restaurants Can Join the Loop

Getting involved is easier than recycling cans. Home cooks should keep a dedicated jug under the sink, then use the city’s interactive map to locate the nearest drop-off. Restaurant managers can request a compliance audit and free bin swap through the Grease Management Portal, ensuring health department readiness before the busy holiday frying season. If you generate more than 50 gallons a month, our team at Grease Connections offers rebates up to $0.50 per gallon alongside 24 hour spill response. Book a pickup here. The more grease we capture, the more biodiesel powers local buses, and the cleaner our lakes remain.

What’s Next: Aviation Fuel and Net-Zero 2030 Goals

Orlando’s program is scaling beyond road transport. Cleaned yellow grease now ships to Neste’s Gulf Coast refinery, where it becomes sustainable aviation fuel (SAF) for flights out of MCO. Meanwhile, the city’s 2030 Action Plan calls for tripling household participation and introducing neighborhood “grease holidays” during Thanksgiving and Super Bowl weekends. With new drop boxes planned for every district and potential biogas to electricity integration at the Iron Bridge wastewater plant, Orlando is on course to make waste to fuel as routine as curbside recycling. Your leftover fry oil could soon help a plane take off, proof that small kitchen habits drive global change.