Table of Contents

I’ll never forget the day a restaurant owner in Miami asked me point-blank: “Jorge, is this recycling thing actually making a difference, or are we just moving pollution from one place to another?”

Standing next to his grease container behind a busy Cuban restaurant, I realized this wasn’t just about collecting oil anymore. After 10 years in the used cooking oil industry, I’d heard every question imaginable. But this one? This one mattered.

Because here’s what most people don’t know: Used cooking oil biodiesel achieves 79% to 86% lower lifecycle emissions biodiesel used cooking oil compared to petroleum diesel. That’s not a typo. We’re talking about turning restaurant waste into fuel that’s fundamentally cleaner than what’s pumping through millions of diesel engines right now.

The $11.8 Billion Market in Restaurant Kitchens

Let me share something that might surprise you: The global used cooking oil vs diesel emissions debate isn’t just environmental—it’s economic. The global used cooking oil market was valued at $6.4 billion in 2023, and is projected to reach $11.8 billion by 2034.

Think about that. We’re sitting on an $11.8 billion industry that most people still see as waste.

But here’s the kicker: In 2022, global supplies of UCO were estimated at 3.7 billion gallons, with U.S. collection reaching 0.85 billion gallons. Industry experts estimate we’re only collecting about 30% of available UCO globally. That means there’s roughly 8 billion gallons going uncollected—straight into sewers or landfills.

The Diesel Problem Nobody Talks About

Every morning, I drive past hundreds of diesel trucks heading to the Port of Miami. In the U.S. alone, the transportation sector burns approximately 3 million barrels of diesel every day, resulting in 10% of the country’s total energy-related carbon dioxide emissions.

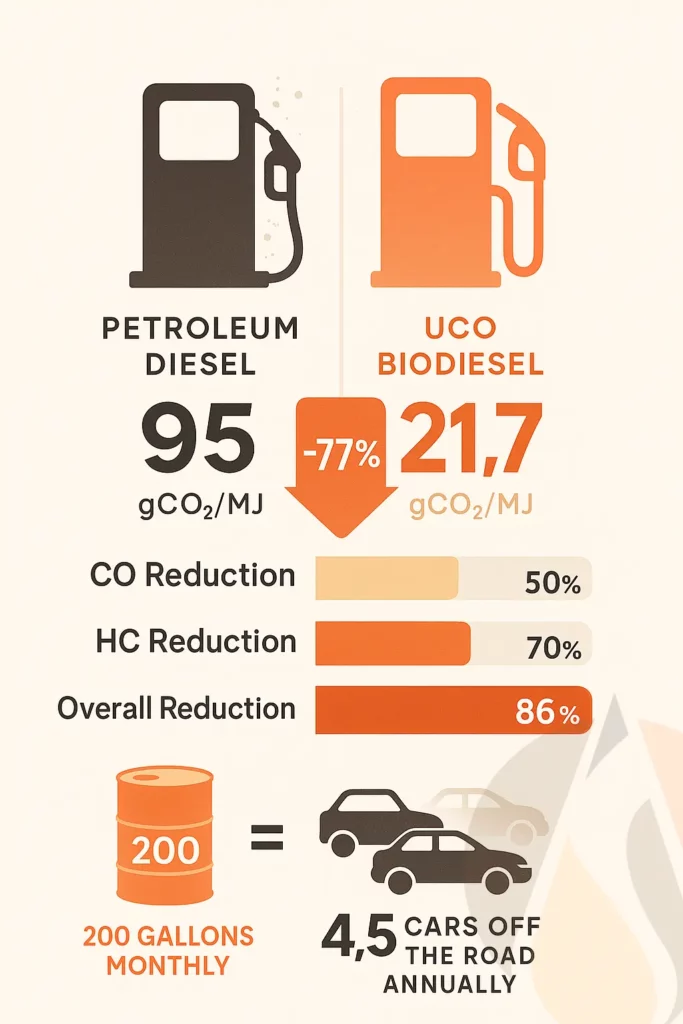

But here’s where the biodiesel carbon footprint comparison gets interesting: UCO-derived biodiesel has a significantly lower carbon footprint with a carbon intensity score of 21.7 gCO2/MJ, compared to petroleum diesel’s 95 gCO2/MJ. That’s not just a reduction—it’s a transformation.

The Numbers That Changed Everything

When I first started in this business, I thought we were just helping restaurants dispose of waste responsibly. Then I dove into the actual cooking oil biodiesel emissions data, and honestly? It blew my mind.

A comprehensive life cycle analysis from Shanghai revealed that biodiesel from used cooking oil produces only 359.33 kg of CO2 per ton of biodiesel – just 11.61% of petroleum diesel’s emissions.

But here’s what makes this even more compelling for businesses: The economics are shifting dramatically. UCO is the MOST subsidized oil that enters the American biofuel system because it has the lowest carbon intensity of any biodiesel feedstock.

The Real-World Emissions Breakdown

Let’s talk about the biodiesel vs petroleum diesel environmental impact at the tailpipe:

Carbon Monoxide (CO): CO emissions for biodiesel blends were significantly lower than diesel fuel—up to 50% reduction.

Hydrocarbons (HC): The EPA found that pure biodiesel can reduce HC as high as 70%.

Particulate Matter: Those black clouds from diesel trucks? Cut dramatically with UCO biodiesel.

NOx Emissions: This one’s nuanced. Cooking oil had the lowest oxides of nitrogen emissions, while B100 had the highest. The sweet spot? B5-B20 blends balance performance with emissions.

From Supply Chain Nightmare to Circular Economy Dream

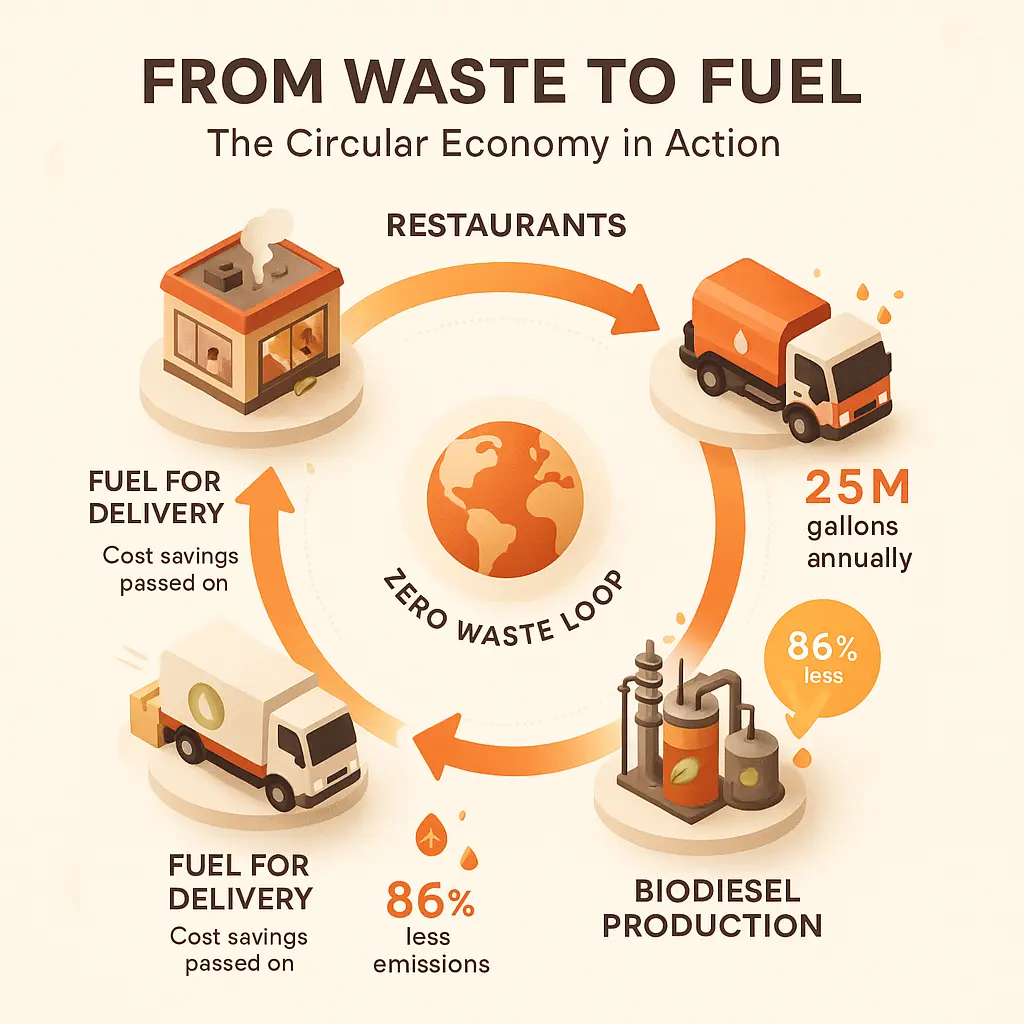

Here’s a story that shows how far we’ve come. Chevron Renewable Energy Group, Sheetz and Restaurant Technologies created a circular economy for processing used cooking oil. Restaurant Technologies collects UCO from over 37,000 commercial kitchens, delivers it to Chevron REG for processing into biodiesel, which Sheetz then sells at their stations.

That’s not just recycling—that’s a complete circular economy in action.

The Economic Revolution Nobody’s Talking About

Let me share some data that will make CFOs sit up straight. The California Low Carbon Fuel Standard (LCFS) creates credits where each represents one metric ton of carbon dioxide reduced. For restaurant owners, this translates to real money.

Here’s how the UCO biodiesel greenhouse gas reduction creates value:

- LCFS credits can be worth $100-200 per metric ton of CO2 reduced

- A typical restaurant producing 200 gallons of UCO monthly can generate credits worth $2,000-4,000 annually

- Add in the federal $1.00/gallon biodiesel tax credit, and the economics become compelling

The Global Supply Shock Coming Fast

Global supplies of used cooking oil are expected to more than double to 31 million metric tonnes by 2030 from the current 14 million mt. But here’s the challenge: Between 2021 and 2030, Stratas Advisors projects liquid biofuels made from oils and fats like UCO to increase by 14 MMT (+28%).

This creates a massive opportunity. Asia was the largest supplier of UCO, with most of its product exported either as UCO or biomass-based diesel. But with local production ramping up globally, we’re seeing a fundamental shift in the market.

Real Impact, Real Numbers: A Miami Case Study

Last month, I visited a restaurant group generating 200 gallons of UCO monthly. Here’s the complete carbon savings used cooking oil breakdown:

Environmental Impact:

- 200 gallons UCO = 200 gallons biodiesel

- Monthly carbon reduction: 3,800 pounds CO2

- Annual impact: 45,600 pounds CO2 eliminated

- Equivalent to removing 4.5 cars from roads annually

Economic Impact:

- Zero disposal costs (saves $200-400/month)

- LCFS credit potential: $167-333/month

- Creates local jobs in collection and processing

- Protects sewage systems from costly blockages

The Technology Breakthrough That Changes Everything

Just when I thought the industry couldn’t get more exciting, researchers developed a simple, low-temperature process that converts waste cooking oil to biodiesel at just above room temperature, converting about 85% of used cooking oil into industry-standard biodiesel.

This breakthrough means:

- Small restaurants could potentially process their own fuel

- Lower energy requirements = lower costs

- Simpler technology = wider adoption potential

Why California is 20 Years Ahead

Here’s a stat that shows where we’re headed: 70% of the diesel consumed in California comes from biofuels. California didn’t get there overnight—it took smart policy and infrastructure investment.

The rest of the country is catching up. Europe accounted for a share of more than 46.7% of the global biodiesel market in 2021, showing this isn’t just a California phenomenon.

The Jobs Revolution in Your Neighborhood

Promoting biofuels can have a positive effect on employment; the creation of new green jobs, such as UCO collectors, can enhance the local and circular economy.

In South Florida alone, I’ve watched the UCO collection industry create:

- 500+ direct collection jobs

- 200+ processing facility positions

- Countless indirect jobs in logistics and support

- Average wages 20% above minimum wage

Addressing the Elephant in the Room: Performance

I hear it all the time: “But does biodiesel really perform as well?”

Here’s what the data shows: B5 provided the best balance of performance, emissions, fuel economy, and convenience. Modern engines run B5-B20 blends without any modifications.

For heavy-duty applications, Restaurant Technologies will initially utilize a B30-B50 blend, 30-50% InfiniD™ (biodiesel), with the remainder petroleum diesel in their commercial fleet—proving high-blend biodiesel works in real-world conditions.

The Future is Already Here—Just Not Evenly Distributed

The global used cooking oil market was estimated to be around USD 7 billion in 2024… expected to grow from USD 7.4 billion in 2025 to USD 12.2 billion by 2034.

But growth isn’t just about market size. It’s about infrastructure. Europe currently dominates the used cooking oil market, accounting for a share of 44.3% in 2024, while The used cooking oil market from household cooking oil segment was valued at USD 2.8 billion in 2024, and it is anticipated to expand by 5.9% CAGR.

Your Role in the $12 Billion Revolution

After a decade in this industry, I can tell you with absolute certainty: We’re at a tipping point. Life cycle analysis shows emissions for 100% biodiesel are 74% lower than petroleum diesel.

Here’s what restaurant owners need to know:

- Your waste has measurable value—both environmental and economic

- Collection infrastructure is expanding rapidly—if it’s not in your area yet, it will be soon

- The economics work today—between avoided disposal costs and potential credits, ROI is immediate

- You’re part of the solution—every gallon counts in fighting climate change

The Bottom Line That Matters

That restaurant owner in Miami? After seeing these numbers, he didn’t just sign up for our service. He became an advocate, bringing five other restaurants into the program within two months.

Because here’s the undeniable truth: Converting tallow, used cooking oil, and distillers corn oil to biodiesel could achieve higher GHG reductions of 79% to 86% lower than petroleum diesel.

This isn’t marginal improvement. This is transformative change hiding in plain sight.

Every time I collect used cooking oil, I’m not just providing a service. I’m part of a solution that’s reducing carbon emissions by up to 86%, preventing water pollution, creating jobs, and building a circular economy that benefits everyone.

The question isn’t whether UCO biodiesel is better than petroleum diesel. The data is crystal clear on that. The question is: How quickly can we scale this solution?

Because every day we wait, that’s another 3 million barrels of petroleum diesel burned. Another day of preventable emissions. Another day we could have been converting waste into wealth.

Your used cooking oil isn’t waste. It’s liquid gold for our planet’s future—and your bottom line.

Ready to turn your restaurant’s waste oil into clean fuel and join the $12 billion revolution? The future isn’t just greener than you think—it’s more profitable too.

About the Author: Jorge Argota has spent over 10 years in the used cooking oil collection and recycling industry, helping restaurants across South Florida turn their waste into renewable fuel. He’s passionate about showing businesses how environmental responsibility and profitability go hand in hand.